Precipitation-hardened alloys gain strength through the formation of fine particles within the metal matrix, providing superior hardness and resistance to deformation under stress. Solution-hardened alloys achieve increased strength by dissolving alloying elements uniformly in the base metal, enhancing ductility and toughness while maintaining corrosion resistance. Choosing between precipitation-hardened and solution-hardened alloys depends on the desired balance between mechanical strength, workability, and environmental durability for specific applications.

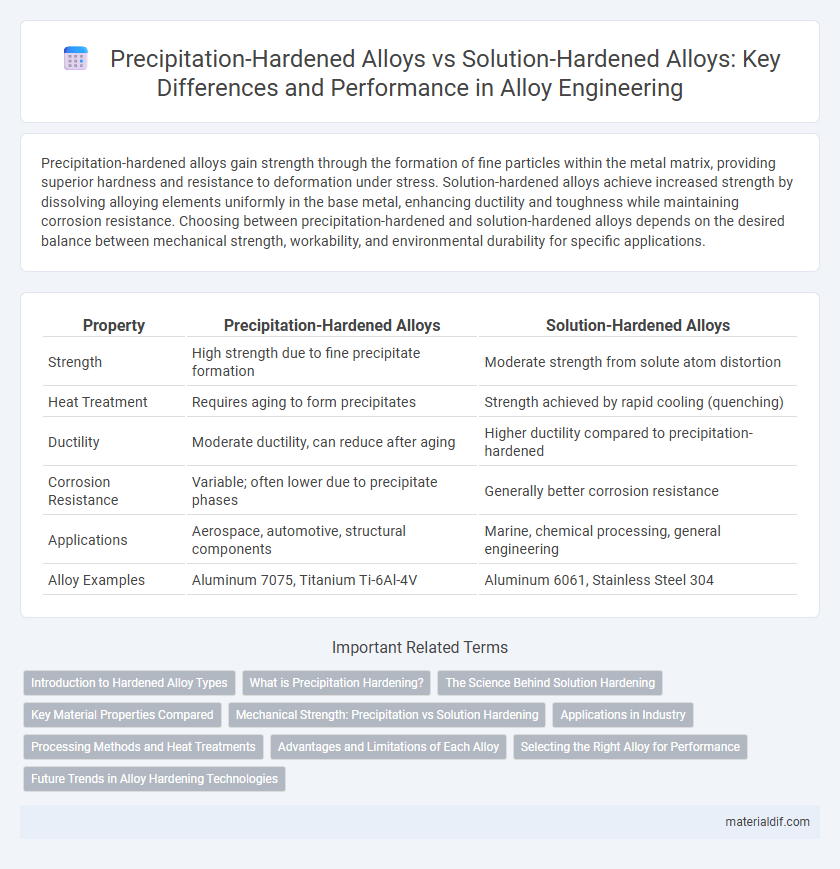

Table of Comparison

| Property | Precipitation-Hardened Alloys | Solution-Hardened Alloys |

|---|---|---|

| Strength | High strength due to fine precipitate formation | Moderate strength from solute atom distortion |

| Heat Treatment | Requires aging to form precipitates | Strength achieved by rapid cooling (quenching) |

| Ductility | Moderate ductility, can reduce after aging | Higher ductility compared to precipitation-hardened |

| Corrosion Resistance | Variable; often lower due to precipitate phases | Generally better corrosion resistance |

| Applications | Aerospace, automotive, structural components | Marine, chemical processing, general engineering |

| Alloy Examples | Aluminum 7075, Titanium Ti-6Al-4V | Aluminum 6061, Stainless Steel 304 |

Introduction to Hardened Alloy Types

Precipitation-hardened alloys achieve increased strength through the formation of fine particles that hinder dislocation movement during aging heat treatments, enhancing mechanical properties. Solution-hardened alloys rely on the uniform distribution of alloying elements dissolved within the metal matrix, creating lattice distortions that impede dislocation motion for improved hardness and strength. These hardening mechanisms are fundamental to tailoring alloy performance for aerospace, automotive, and structural applications.

What is Precipitation Hardening?

Precipitation hardening, also known as age hardening, is a heat treatment process that increases the strength and hardness of alloys by forming finely dispersed particles within the metal matrix. These precipitates hinder dislocation movement, significantly enhancing mechanical properties compared to solution-hardened alloys, where alloying elements remain in a solid solution. Common precipitation-hardened alloys include aluminum, titanium, and nickel-based superalloys used in aerospace and automotive industries.

The Science Behind Solution Hardening

Solution hardening occurs when solute atoms dissolve uniformly within the solvent metal's crystal lattice, creating lattice distortions that impede dislocation motion and increase alloy strength. This atomic-level interaction enhances mechanical properties without compromising ductility, making solution-hardened alloys ideal for structural applications. The effectiveness depends on factors such as solute concentration, atomic size difference, and material temperature during alloy formation.

Key Material Properties Compared

Precipitation-hardened alloys exhibit superior strength and hardness due to fine, uniformly distributed secondary phase particles that impede dislocation motion, whereas solution-hardened alloys gain strength primarily from solute atom distortion within the crystal lattice. These precipitation-hardened alloys typically offer enhanced thermal stability and resistance to creep compared to solution-hardened alloys, which may lose strength at elevated temperatures due to solute atom diffusion. Corrosion resistance varies by alloy composition but generally, solution-hardened alloys show improved ductility and toughness, making them suitable for applications requiring moderate strength with enhanced formability.

Mechanical Strength: Precipitation vs Solution Hardening

Precipitation-hardened alloys exhibit superior mechanical strength due to finely distributed secondary phase particles that impede dislocation movement more effectively than the solute atoms in solution-hardened alloys. The coherent precipitates formed during aging create strong obstacles to slip, resulting in higher yield and tensile strength. In contrast, solution hardening relies on atomic size mismatch and modulus differences, which produce less significant barriers to dislocation glide.

Applications in Industry

Precipitation-hardened alloys are extensively used in aerospace and automotive industries due to their superior strength-to-weight ratio and excellent corrosion resistance, enabling high-performance engine components and structural parts. Solution-hardened alloys find applications in marine and chemical processing industries where resistance to stress corrosion cracking and enhanced toughness are essential for pumps, valves, and heat exchangers. Both alloy types contribute significantly to advanced manufacturing with tailored mechanical properties suited for demanding environmental conditions.

Processing Methods and Heat Treatments

Precipitation-hardened alloys undergo controlled aging heat treatments to form finely distributed precipitates that enhance strength, typically involving solution treatment followed by quenching and aging at elevated temperatures. Solution-hardened alloys achieve strengthening by dissolving alloying elements uniformly in the matrix at high temperatures, followed by rapid quenching to retain a supersaturated solid solution without significant precipitation. Processing methods for precipitation-hardened alloys emphasize precise temperature control during aging to optimize precipitate size and distribution, whereas solution-hardened alloys rely on rapid cooling rates to lock alloying elements in solution for increased hardness and ductility.

Advantages and Limitations of Each Alloy

Precipitation-hardened alloys offer superior strength and hardness due to finely dispersed particles formed during heat treatment, enhancing mechanical properties and resistance to wear, but they can be prone to over-aging and decreased toughness over time. Solution-hardened alloys provide improved ductility and corrosion resistance by dissolving alloying elements uniformly within the metal matrix, yet they have lower ultimate strength compared to precipitation-hardened alloys and are less effective at high-temperature applications. Each alloy type balances performance characteristics based on the intended use, with precipitation-hardened alloys favored for aerospace and automotive parts requiring high strength, while solution-hardened alloys suit applications needing better formability and corrosion resistance.

Selecting the Right Alloy for Performance

Precipitation-hardened alloys offer superior strength and hardness due to finely dispersed particles formed during heat treatment, making them ideal for applications requiring high performance under stress. Solution-hardened alloys rely on solute atoms dissolved in the metal matrix to enhance strength and corrosion resistance, suitable for environments demanding durability and toughness. Selecting the right alloy depends on balancing mechanical properties, environmental conditions, and manufacturing processes to optimize performance and longevity.

Future Trends in Alloy Hardening Technologies

Precipitation-hardened alloys are evolving with nanoscale precipitate engineering to enhance strength and corrosion resistance, while solution-hardened alloys focus on advanced solute distribution for improved ductility and thermal stability. Emerging technologies such as additive manufacturing and machine learning-driven alloy design enable precise control over microstructural features, accelerating the development of high-performance alloys. Future trends emphasize sustainable processing techniques and multi-scale modeling to optimize hardening mechanisms for aerospace, automotive, and energy sectors.

Precipitation-hardened alloys vs Solution-hardened alloys Infographic

materialdif.com

materialdif.com