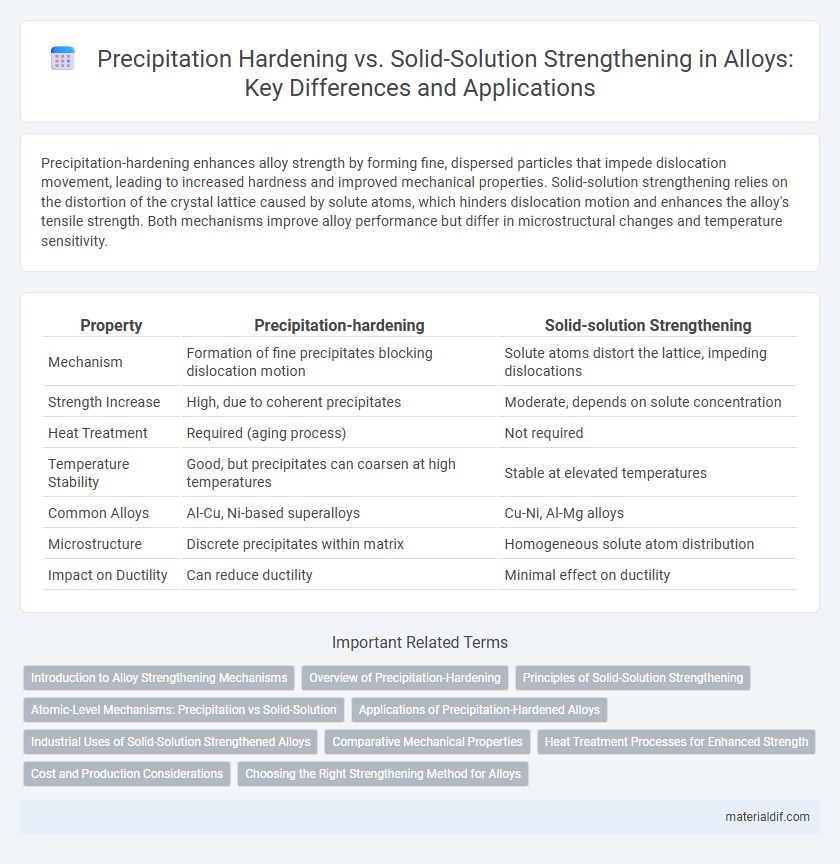

Precipitation-hardening enhances alloy strength by forming fine, dispersed particles that impede dislocation movement, leading to increased hardness and improved mechanical properties. Solid-solution strengthening relies on the distortion of the crystal lattice caused by solute atoms, which hinders dislocation motion and enhances the alloy's tensile strength. Both mechanisms improve alloy performance but differ in microstructural changes and temperature sensitivity.

Table of Comparison

| Property | Precipitation-hardening | Solid-solution Strengthening |

|---|---|---|

| Mechanism | Formation of fine precipitates blocking dislocation motion | Solute atoms distort the lattice, impeding dislocations |

| Strength Increase | High, due to coherent precipitates | Moderate, depends on solute concentration |

| Heat Treatment | Required (aging process) | Not required |

| Temperature Stability | Good, but precipitates can coarsen at high temperatures | Stable at elevated temperatures |

| Common Alloys | Al-Cu, Ni-based superalloys | Cu-Ni, Al-Mg alloys |

| Microstructure | Discrete precipitates within matrix | Homogeneous solute atom distribution |

| Impact on Ductility | Can reduce ductility | Minimal effect on ductility |

Introduction to Alloy Strengthening Mechanisms

Precipitation-hardening in alloys occurs through the formation of fine, dispersed particles that obstruct dislocation movement, significantly enhancing strength by creating barriers within the metal's microstructure. Solid-solution strengthening relies on the incorporation of solute atoms into the solvent metal lattice, causing lattice distortions that impede dislocation motion and improve mechanical properties. Both mechanisms are fundamental in tailoring alloy performance by manipulating microstructural features to resist deformation under stress.

Overview of Precipitation-Hardening

Precipitation-hardening in alloys enhances mechanical strength by forming fine, dispersed secondary phase particles within the metal matrix, which hinder dislocation movement. This process typically involves solution treatment, quenching, and aging to control precipitate size and distribution, resulting in improved hardness and yield strength. Compared to solid-solution strengthening, which relies on lattice distortions from solute atoms, precipitation-hardening provides superior strength through coherent or semi-coherent precipitates that effectively obstruct dislocation glide.

Principles of Solid-Solution Strengthening

Solid-solution strengthening enhances alloy strength by introducing impurity atoms into the host metal's crystal lattice, creating lattice distortions that impede dislocation movement. These distortions increase the yield strength proportional to the size and concentration of solute atoms, with substitutional and interstitial solutes producing different effects. The resulting strain fields around solute atoms interact with dislocations, raising the stress required for plastic deformation and improving mechanical hardness without the need for phase transformations or heat treatments.

Atomic-Level Mechanisms: Precipitation vs Solid-Solution

Precipitation-hardening enhances alloy strength by forming nanoscale secondary phase particles that obstruct dislocation motion through coherency strain and modulus mismatch at the atomic level. Solid-solution strengthening relies on atomic size and modulus differences between solute and solvent atoms, causing localized lattice distortions that impede dislocation glide. The key atomic mechanism in precipitation-hardening is particle-dislocation interaction, while solid-solution strengthening depends on solute atom-dislocation elastic interactions.

Applications of Precipitation-Hardened Alloys

Precipitation-hardened alloys exhibit enhanced mechanical properties through the formation of finely dispersed particles, making them ideal for aerospace components, automotive parts, and high-performance turbines requiring superior strength and fatigue resistance. These alloys outperform solid-solution strengthened materials in applications demanding elevated temperature stability and wear resistance, such as jet engine blades and structural airframe elements. Their ability to maintain hardness and toughness under cyclic stresses significantly expands their use in critical engineering applications.

Industrial Uses of Solid-Solution Strengthened Alloys

Solid-solution strengthening enhances alloy performance by introducing impurity atoms that distort the crystal lattice, improving strength and corrosion resistance without compromising ductility. Industrially, these alloys are widely used in aerospace components, automotive parts, and marine applications where moderate strength combined with excellent toughness and weldability is essential. Compared to precipitation-hardening alloys, solid-solution strengthened alloys offer superior performance under high temperature and corrosive environments, making them crucial in chemical processing and power generation industries.

Comparative Mechanical Properties

Precipitation-hardening alloys exhibit higher yield strength and tensile strength due to the formation of fine, dispersed secondary phases that impede dislocation movement more effectively than solid-solution strengthening, which relies on lattice distortions caused by solute atoms. Precipitation-hardened alloys typically demonstrate superior hardness and improved high-temperature performance, whereas solid-solution strengthened alloys often offer better ductility and corrosion resistance. The balance between strength and toughness in precipitation-hardened alloys makes them ideal for aerospace and automotive applications requiring high mechanical performance.

Heat Treatment Processes for Enhanced Strength

Precipitation-hardening alloys achieve enhanced strength through heat treatment processes that involve solution treatment, quenching, and aging, creating fine, dispersed precipitates that impede dislocation motion. Solid-solution strengthening relies on the uniform distribution of alloying elements within the matrix, with heat treatment primarily optimizing solute atom distribution and lattice distortion. Precipitation-hardening offers superior strength improvements compared to solid-solution strengthening due to the controlled formation of coherent precipitates during aging.

Cost and Production Considerations

Precipitation-hardening alloys often incur higher production costs due to complex heat treatment processes and longer processing times compared to solid-solution strengthened alloys. Solid-solution strengthening typically involves simpler alloying and processing steps, resulting in lower manufacturing expenses and faster production cycles. The selection between these methods depends on balancing performance requirements with cost efficiency in industrial applications.

Choosing the Right Strengthening Method for Alloys

Precipitation-hardening alloys achieve superior strength through finely dispersed secondary phase particles that hinder dislocation motion, making them ideal for applications requiring high strength and toughness. Solid-solution strengthening relies on dissolving alloying elements into the base metal lattice, causing lattice distortions that impede dislocation movement and improve ductility along with moderate strength. Selecting the right method depends on factors like desired mechanical properties, operating temperature, and manufacturing feasibility, where precipitation-hardening suits aerospace components, and solid-solution strengthening fits applications needing greater corrosion resistance and formability.

Precipitation-hardening vs Solid-solution strengthening Infographic

materialdif.com

materialdif.com