Hastelloy C-276 offers excellent resistance to reducing and oxidizing environments, making it ideal for chemical processing applications involving strong acids and high temperatures. Hastelloy C-22 provides superior corrosion resistance in more aggressive environments, including environments with mixed oxidizing and reducing agents, due to its higher chromium content. Both alloys deliver exceptional durability, but C-22 is preferred for more demanding conditions such as those involving strong oxidizers and chloride stress.

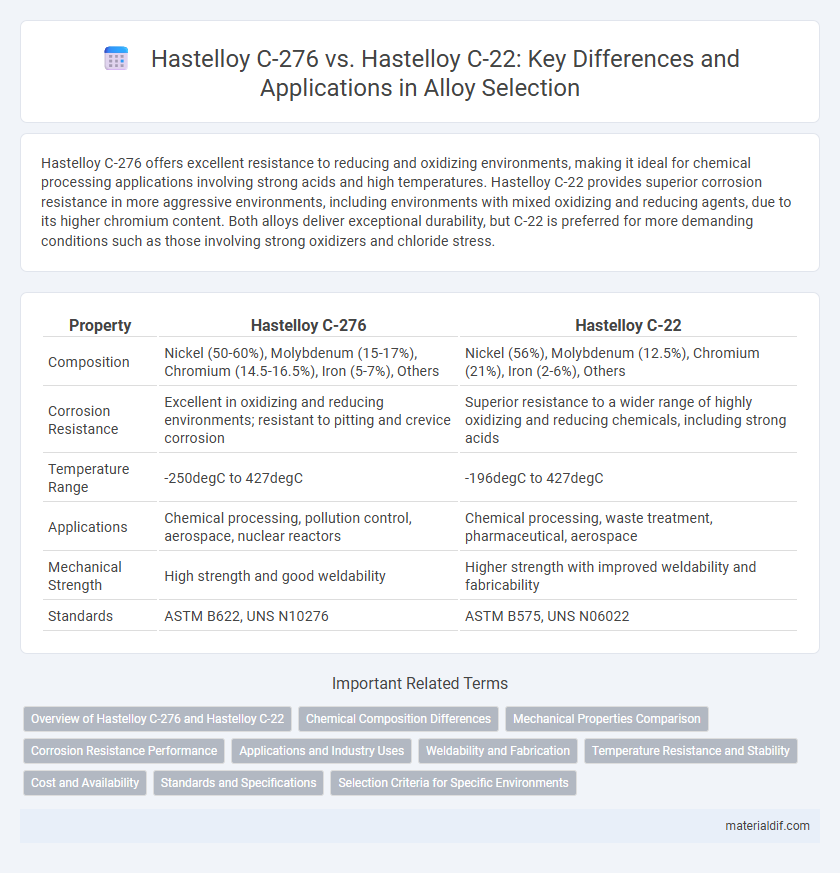

Table of Comparison

| Property | Hastelloy C-276 | Hastelloy C-22 |

|---|---|---|

| Composition | Nickel (50-60%), Molybdenum (15-17%), Chromium (14.5-16.5%), Iron (5-7%), Others | Nickel (56%), Molybdenum (12.5%), Chromium (21%), Iron (2-6%), Others |

| Corrosion Resistance | Excellent in oxidizing and reducing environments; resistant to pitting and crevice corrosion | Superior resistance to a wider range of highly oxidizing and reducing chemicals, including strong acids |

| Temperature Range | -250degC to 427degC | -196degC to 427degC |

| Applications | Chemical processing, pollution control, aerospace, nuclear reactors | Chemical processing, waste treatment, pharmaceutical, aerospace |

| Mechanical Strength | High strength and good weldability | Higher strength with improved weldability and fabricability |

| Standards | ASTM B622, UNS N10276 | ASTM B575, UNS N06022 |

Overview of Hastelloy C-276 and Hastelloy C-22

Hastelloy C-276 is a nickel-molybdenum-chromium alloy renowned for its exceptional corrosion resistance in oxidizing and reducing environments, making it ideal for chemical processing applications. Hastelloy C-22, a more advanced nickel-chromium-molybdenum-iron alloy, offers superior resistance to pitting, crevice corrosion, and stress corrosion cracking, enhancing durability in highly aggressive media. Both alloys are preferred for their strength and chemical stability, but C-22's enhanced composition provides greater performance in harsh, oxidizing conditions.

Chemical Composition Differences

Hastelloy C-276 features a chemical composition primarily consisting of 15-17% molybdenum, 14.5-16.5% chromium, and 3-4.5% iron, offering excellent resistance to a wide range of chemical environments. In contrast, Hastelloy C-22 contains higher chromium and molybdenum levels, with 20-22% chromium and 12-14.5% molybdenum, enhancing its resistance to oxidizing and reducing agents. The increased chromium and molybdenum content in Hastelloy C-22 results in superior corrosion resistance compared to Hastelloy C-276, particularly in aggressive chemical processing environments.

Mechanical Properties Comparison

Hastelloy C-276 exhibits superior tensile strength and excellent corrosion resistance, with a typical tensile strength of around 860 MPa and yield strength near 414 MPa. Hastelloy C-22 offers comparable mechanical properties, but with slightly enhanced resistance to stress corrosion cracking and pitting, maintaining tensile strength approximately 770 MPa and yield strength around 310 MPa. Both alloys provide excellent ductility and toughness, suitable for demanding chemical processing applications, though C-276 tends to perform better under high mechanical stress conditions.

Corrosion Resistance Performance

Hastelloy C-22 exhibits superior corrosion resistance compared to Hastelloy C-276, particularly against oxidizing agents like chlorine and nitric acid. The enhanced chromium and molybdenum content in Hastelloy C-22 makes it more resistant to pitting, crevice corrosion, and stress corrosion cracking. Both alloys perform well in harsh chemical environments, but Hastelloy C-22 is preferred for applications requiring maximum protection against a broader range of aggressive chemicals.

Applications and Industry Uses

Hastelloy C-276 offers exceptional resistance to oxidizing and reducing agents, making it ideal for chemical processing, pollution control, and aerospace applications. Hastelloy C-22 exhibits superior corrosion resistance in aggressive environments containing strong oxidizers and chlorides, commonly used in chemical reactors, heat exchangers, and waste treatment plants. Both alloys are preferred in industries requiring high-performance materials that withstand extreme conditions, but C-22 is often selected for more aggressive or variable chemical environments.

Weldability and Fabrication

Hastelloy C-276 exhibits excellent weldability and ease of fabrication due to its balanced composition of nickel, molybdenum, and chromium, minimizing cracking and distortion during welding. Hastelloy C-22 offers superior corrosion resistance but presents more challenges in weldability, requiring careful control of heat input and filler materials to prevent sensitization and maintain structural integrity. Both alloys support fabrication for chemical processing equipment, but C-276 is generally preferred when welding performance is a critical factor.

Temperature Resistance and Stability

Hastelloy C-276 exhibits superior temperature resistance, maintaining structural integrity up to approximately 1200degF (649degC), making it ideal for high-temperature chemical processing environments. Hastelloy C-22 offers enhanced stability and corrosion resistance at elevated temperatures, particularly excelling in aggressive oxidative and reducing conditions up to around 1300degF (704degC). Both alloys deliver exceptional performance, but C-22's advanced stability under fluctuating thermal and corrosive stresses provides a critical advantage for long-term industrial applications.

Cost and Availability

Hastelloy C-276 typically costs less than Hastelloy C-22 due to its broader availability and less complex alloy composition, making it a more budget-friendly option for corrosion-resistant applications. Hastelloy C-22, while more expensive, offers superior resistance to oxidizing and reducing agents, but its limited production scale impacts both cost and availability. Procurement of Hastelloy C-22 may face longer lead times compared to Hastelloy C-276, which is widely stocked by suppliers globally.

Standards and Specifications

Hastelloy C-276 and Hastelloy C-22 both conform to stringent ASTM and ASME standards, ensuring reliable performance in corrosive environments. Hastelloy C-276 is primarily specified under standards such as ASTM B619 and ASME SB622, while Hastelloy C-22 is governed by ASTM B575 and ASME SB575, reflecting differences in their chemical composition and application suitability. Both alloys meet UNS N10276 and UNS N06022 specifications respectively, highlighting their specific corrosion resistance properties and mechanical strength benchmarks.

Selection Criteria for Specific Environments

Hastelloy C-276 offers superior resistance to a wide range of aggressive chemicals, making it ideal for highly corrosive environments with strong oxidizers and reducing agents, such as chemical processing and waste treatment plants. Hastelloy C-22 excels in environments with elevated temperatures and highly oxidizing conditions, commonly used in aerospace, pollution control, and nuclear reactors, due to its enhanced oxidation resistance and stability. Selection between C-276 and C-22 depends on specific environmental factors like temperature, chemical composition, and stress conditions to ensure optimal corrosion resistance and material performance.

Hastelloy C-276 vs Hastelloy C-22 Infographic

materialdif.com

materialdif.com