Duplex alloys combine austenitic and ferritic microstructures, offering superior corrosion resistance and high strength, making them ideal for harsh environments like chemical processing and marine applications. Martensitic alloys, characterized by their high hardness and wear resistance, are commonly used in applications requiring toughness and strength, such as blades and surgical instruments. The choice between duplex and martensitic alloys depends on the required balance of corrosion resistance versus mechanical properties.

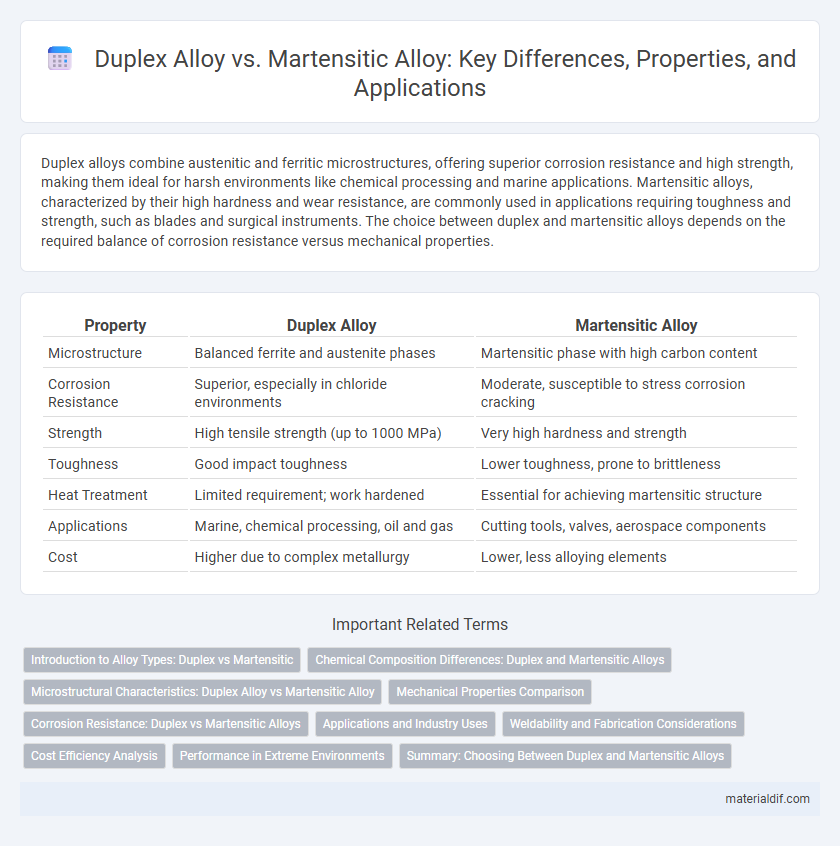

Table of Comparison

| Property | Duplex Alloy | Martensitic Alloy |

|---|---|---|

| Microstructure | Balanced ferrite and austenite phases | Martensitic phase with high carbon content |

| Corrosion Resistance | Superior, especially in chloride environments | Moderate, susceptible to stress corrosion cracking |

| Strength | High tensile strength (up to 1000 MPa) | Very high hardness and strength |

| Toughness | Good impact toughness | Lower toughness, prone to brittleness |

| Heat Treatment | Limited requirement; work hardened | Essential for achieving martensitic structure |

| Applications | Marine, chemical processing, oil and gas | Cutting tools, valves, aerospace components |

| Cost | Higher due to complex metallurgy | Lower, less alloying elements |

Introduction to Alloy Types: Duplex vs Martensitic

Duplex alloys combine austenitic and ferritic microstructures, offering a balanced composition that provides enhanced strength and corrosion resistance, particularly in chloride environments. Martensitic alloys feature a predominantly martensitic microstructure, known for high hardness and moderate corrosion resistance, commonly used in applications requiring wear resistance and toughness. Understanding these fundamental differences aids in selecting the appropriate alloy for demanding industrial applications such as chemical processing and marine engineering.

Chemical Composition Differences: Duplex and Martensitic Alloys

Duplex alloys feature a balanced microstructure of approximately 50% austenite and 50% ferrite, with chemical composition typically containing 18-28% chromium, 4-7% nickel, and 2-5% molybdenum, enhancing corrosion resistance and strength. Martensitic alloys primarily consist of 12-17% chromium with lower nickel content, and carbon levels ranging from 0.1% to 1.2%, which contribute to high hardness and wear resistance but reduced corrosion resistance compared to duplex grades. The significant differences in chromium, nickel, and carbon contents between duplex and martensitic alloys dictate their distinct mechanical properties and suitability for various applications.

Microstructural Characteristics: Duplex Alloy vs Martensitic Alloy

Duplex alloys exhibit a balanced microstructure consisting of approximately equal parts austenite and ferrite, enhancing corrosion resistance and mechanical strength. Martensitic alloys feature a predominantly martensitic phase with a body-centered tetragonal structure, providing high hardness and tensile strength but reduced corrosion resistance. The microstructural contrast directly influences their performance in applications requiring toughness and durability.

Mechanical Properties Comparison

Duplex alloys exhibit a balanced combination of high strength and excellent corrosion resistance due to their mixed austenitic-ferritic microstructure, offering superior toughness and fatigue resistance compared to martensitic alloys. Martensitic alloys, characterized by their body-centered tetragonal structure, deliver higher hardness and tensile strength but typically display lower ductility and corrosion resistance. The choice between duplex and martensitic alloys depends on the specific application requirements, prioritizing toughness and corrosion performance or maximum hardness and strength.

Corrosion Resistance: Duplex vs Martensitic Alloys

Duplex alloys exhibit superior corrosion resistance compared to martensitic alloys due to their balanced microstructure of austenite and ferrite, which enhances resistance to pitting and stress corrosion cracking. Martensitic alloys, characterized by a predominantly martensitic phase, generally have lower corrosion resistance and are more susceptible to localized corrosion in aggressive environments. This makes duplex alloys preferable for applications in highly corrosive settings such as chemical processing and marine environments.

Applications and Industry Uses

Duplex alloys, characterized by their balanced austenitic and ferritic phases, excel in chemical processing, oil and gas industries, and marine applications due to their superior corrosion resistance and high strength. Martensitic alloys, known for their hardenability and wear resistance, are widely used in aerospace, automotive, and tooling industries where high mechanical strength and toughness are critical. The selection between duplex and martensitic alloys depends on the specific environmental conditions and mechanical demands of the application.

Weldability and Fabrication Considerations

Duplex alloys offer superior weldability compared to martensitic alloys due to their balanced microstructure of ferrite and austenite, which reduces the risk of cracking and distortion during fabrication. Martensitic alloys, characterized by high carbon content and hardness, require precise control of heat input and post-weld heat treatment to prevent brittleness and maintain mechanical properties. Fabricators prioritize duplex alloys for applications demanding excellent corrosion resistance and structural integrity, while martensitic alloys are chosen for wear-resistant components requiring rigorous welding protocols.

Cost Efficiency Analysis

Duplex alloys offer superior cost efficiency by combining high strength with excellent corrosion resistance, reducing maintenance and replacement expenses in harsh environments. Martensitic alloys, while generally less expensive upfront, often incur higher lifecycle costs due to lower corrosion resistance and more frequent repairs. Choosing duplex alloys optimizes total cost of ownership in industrial applications requiring long-term durability.

Performance in Extreme Environments

Duplex alloys exhibit superior corrosion resistance and enhanced strength in extreme environments due to their balanced austenitic and ferritic microstructure, making them ideal for harsh chemical and marine applications. Martensitic alloys offer high hardness and excellent wear resistance but typically have lower corrosion resistance, which can limit their performance in highly corrosive or high-temperature conditions. The choice between duplex and martensitic alloys depends on the specific environmental stresses, with duplex alloys preferred for combined mechanical and corrosive resistance while martensitic alloys excel in applications demanding high strength and hardness.

Summary: Choosing Between Duplex and Martensitic Alloys

Duplex alloys offer a balanced combination of high strength and excellent corrosion resistance, making them ideal for aggressive environments like chemical processing and marine applications. Martensitic alloys provide superior hardness and wear resistance, suitable for applications requiring impact strength and precision machining, such as turbine blades and cutting tools. Selecting between duplex and martensitic alloys depends on the specific mechanical requirements and environmental conditions, with duplex favored for corrosion resilience and martensitic preferred for hardness and toughness.

Duplex Alloy vs Martensitic Alloy Infographic

materialdif.com

materialdif.com