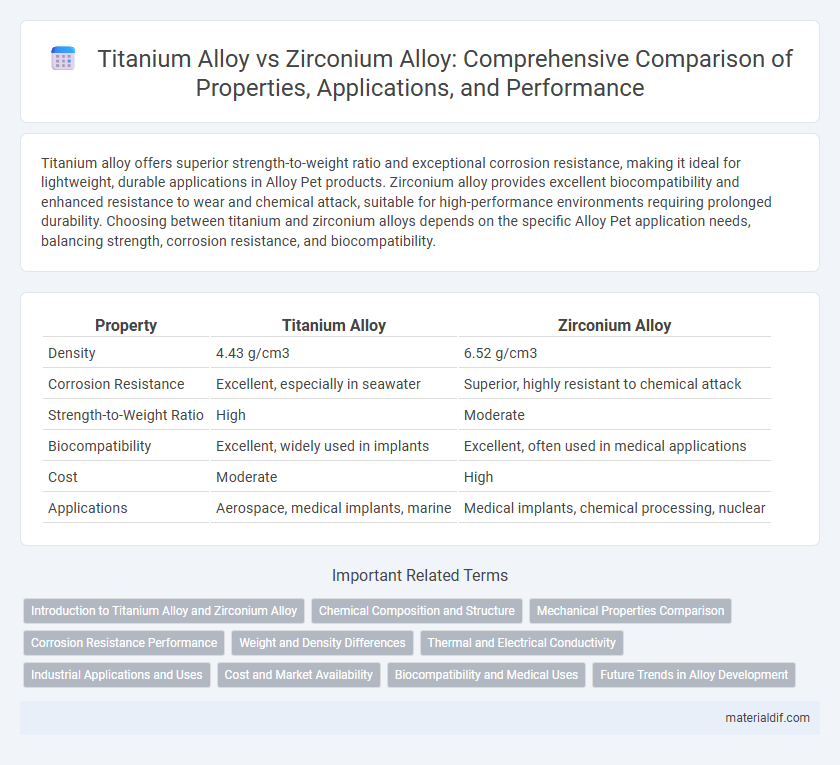

Titanium alloy offers superior strength-to-weight ratio and exceptional corrosion resistance, making it ideal for lightweight, durable applications in Alloy Pet products. Zirconium alloy provides excellent biocompatibility and enhanced resistance to wear and chemical attack, suitable for high-performance environments requiring prolonged durability. Choosing between titanium and zirconium alloys depends on the specific Alloy Pet application needs, balancing strength, corrosion resistance, and biocompatibility.

Table of Comparison

| Property | Titanium Alloy | Zirconium Alloy |

|---|---|---|

| Density | 4.43 g/cm3 | 6.52 g/cm3 |

| Corrosion Resistance | Excellent, especially in seawater | Superior, highly resistant to chemical attack |

| Strength-to-Weight Ratio | High | Moderate |

| Biocompatibility | Excellent, widely used in implants | Excellent, often used in medical applications |

| Cost | Moderate | High |

| Applications | Aerospace, medical implants, marine | Medical implants, chemical processing, nuclear |

Introduction to Titanium Alloy and Zirconium Alloy

Titanium alloys are renowned for their high strength-to-weight ratio, excellent corrosion resistance, and biocompatibility, making them ideal for aerospace, medical implants, and marine applications. Zirconium alloys exhibit superior corrosion resistance, especially in aggressive environments such as nuclear reactors, due to their low neutron absorption and exceptional thermal stability. Both alloys combine metallic elements to enhance mechanical properties and resist degradation, but titanium alloys emphasize lightweight strength while zirconium alloys prioritize chemical durability and radiation resistance.

Chemical Composition and Structure

Titanium alloys primarily consist of titanium with varying amounts of aluminum, vanadium, and iron, offering a hexagonal close-packed (HCP) alpha-phase structure that enhances strength and corrosion resistance. Zirconium alloys, composed mainly of zirconium with tin, iron, and chromium additions, exhibit a similar HCP structure but have superior neutron absorption and resistance to corrosion in nuclear reactors. The differing elemental compositions directly influence their microstructures, resulting in titanium alloys having higher strength-to-weight ratios while zirconium alloys provide better radiological performance and chemical stability.

Mechanical Properties Comparison

Titanium alloys exhibit exceptional strength-to-weight ratios, offering tensile strengths up to 1,200 MPa and excellent fatigue resistance, making them ideal for aerospace and biomedical applications. Zirconium alloys, while slightly lower in tensile strength around 800 MPa, provide superior corrosion resistance and enhanced ductility, which is beneficial in nuclear reactors and chemical processing environments. Both alloys demonstrate significant differences in modulus of elasticity, with titanium alloys averaging 110 GPa compared to zirconium alloys' 90 GPa, influencing their deformation behaviors under mechanical stress.

Corrosion Resistance Performance

Titanium alloys exhibit superior corrosion resistance in highly aggressive environments such as seawater and acidic solutions due to the formation of a stable oxide layer. Zirconium alloys demonstrate exceptional corrosion resistance in nuclear reactors, especially against high-temperature water and steam. The choice between titanium and zirconium alloys depends on specific application requirements, balancing corrosion resistance with mechanical properties and cost.

Weight and Density Differences

Titanium alloys have a density of approximately 4.5 g/cm3, making them significantly lighter than zirconium alloys, which typically have a density around 6.5 g/cm3. The lower density of titanium alloys translates into reduced weight, providing advantages in aerospace and automotive applications where weight savings are critical. Zirconium alloys, despite their higher density, offer superior corrosion resistance, but their increased weight limits their use in weight-sensitive designs.

Thermal and Electrical Conductivity

Titanium alloys typically exhibit lower thermal conductivity, averaging around 6.7 W/m*K, compared to zirconium alloys which range near 20 W/m*K, making zirconium alloys more efficient for heat dissipation applications. In terms of electrical conductivity, titanium alloys possess about 1.8% IACS (International Annealed Copper Standard), significantly lower than zirconium alloys which can reach approximately 1% IACS, both being relatively poor conductors but titanium alloys are slightly better in this regard. The distinct thermal and electrical conductivities influence their suitability in aerospace, biomedical, and nuclear industries where heat management and electrical insulation are critical.

Industrial Applications and Uses

Titanium alloys are widely used in aerospace, medical implants, and chemical processing due to their high strength-to-weight ratio, corrosion resistance, and biocompatibility. Zirconium alloys find primary applications in nuclear reactors and chemical industries, valued for their excellent resistance to heat and corrosion, particularly in aggressive environments. Industrial use of titanium alloys prioritizes lightweight durability, while zirconium alloys are critical for high-temperature corrosion resistance and neutron transparency.

Cost and Market Availability

Titanium alloys generally command higher costs due to their complex extraction and processing methods, while zirconium alloys often have moderate pricing but are less widely available. The titanium alloy market benefits from broader industrial demand, particularly in aerospace and medical sectors, ensuring better availability and supply chain robustness. Zirconium alloys, although advantageous in corrosion resistance, face limited market penetration and niche applications, restricting their accessibility and driving up relative costs.

Biocompatibility and Medical Uses

Titanium alloys exhibit superior biocompatibility due to their excellent corrosion resistance and ability to osseointegrate, making them ideal for orthopedic implants and dental prosthetics. Zirconium alloys, while also biocompatible, offer enhanced wear resistance and radiopacity, which benefits cardiovascular stents and surgical instruments. Both alloys are extensively used in medical applications, but titanium's proven track record in load-bearing implants often makes it the preferred choice.

Future Trends in Alloy Development

Emerging trends in alloy development emphasize enhancing corrosion resistance, strength-to-weight ratio, and biocompatibility in titanium and zirconium alloys for aerospace and medical applications. Titanium alloys continue evolving with additive manufacturing techniques enabling complex, lightweight structures, while zirconium alloys gain attention for nuclear reactors due to superior neutron absorption and high-temperature stability. Advancements in nanostructuring and hybrid alloy compositions are poised to drive next-generation materials with tailored mechanical and chemical properties.

Titanium alloy vs Zirconium alloy Infographic

materialdif.com

materialdif.com