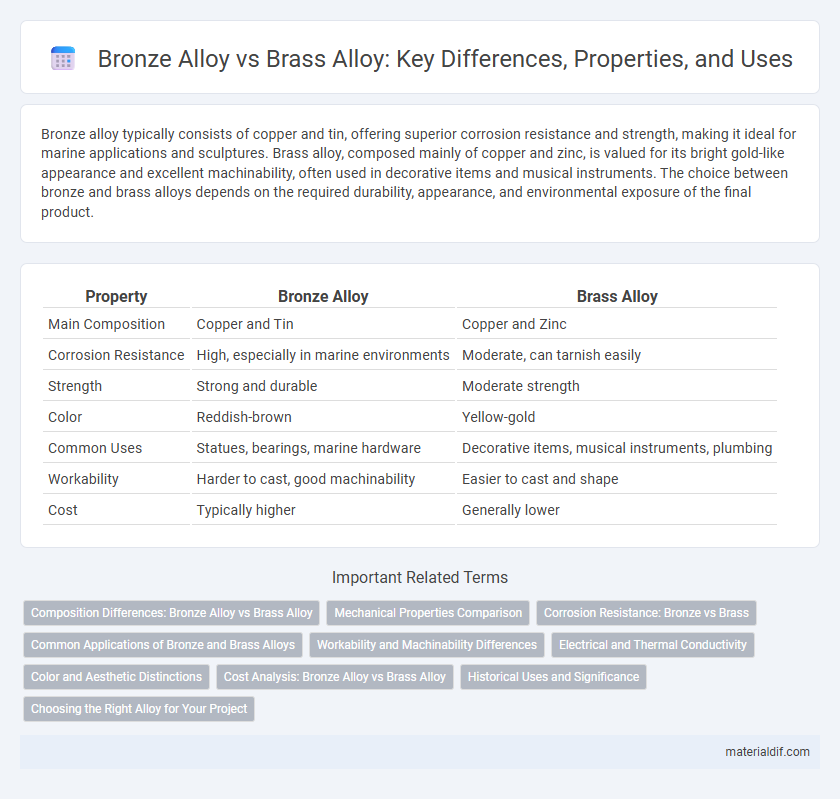

Bronze alloy typically consists of copper and tin, offering superior corrosion resistance and strength, making it ideal for marine applications and sculptures. Brass alloy, composed mainly of copper and zinc, is valued for its bright gold-like appearance and excellent machinability, often used in decorative items and musical instruments. The choice between bronze and brass alloys depends on the required durability, appearance, and environmental exposure of the final product.

Table of Comparison

| Property | Bronze Alloy | Brass Alloy |

|---|---|---|

| Main Composition | Copper and Tin | Copper and Zinc |

| Corrosion Resistance | High, especially in marine environments | Moderate, can tarnish easily |

| Strength | Strong and durable | Moderate strength |

| Color | Reddish-brown | Yellow-gold |

| Common Uses | Statues, bearings, marine hardware | Decorative items, musical instruments, plumbing |

| Workability | Harder to cast, good machinability | Easier to cast and shape |

| Cost | Typically higher | Generally lower |

Composition Differences: Bronze Alloy vs Brass Alloy

Bronze alloy primarily consists of copper and tin, with tin content typically ranging from 5% to 20%, resulting in enhanced hardness and corrosion resistance. Brass alloy, on the other hand, is mainly composed of copper and zinc, with zinc content varying between 5% and 40%, contributing to its increased ductility and machinability. The distinct elemental compositions of bronze and brass alloys directly influence their mechanical properties and common applications in industries such as construction, marine, and musical instruments.

Mechanical Properties Comparison

Bronze alloys typically exhibit higher tensile strength and superior corrosion resistance compared to brass alloys, making them ideal for heavy-duty applications. Brass alloys offer greater malleability and better machinability, which suits intricate components requiring detailed shaping. Both alloys vary in hardness and fatigue resistance, with bronze generally outperforming brass in durability under mechanical stress.

Corrosion Resistance: Bronze vs Brass

Bronze alloy, primarily composed of copper and tin, exhibits superior corrosion resistance compared to brass alloy, which consists mainly of copper and zinc. The tin content in bronze forms a protective oxide layer that enhances durability in marine and industrial environments. Brass, while offering good corrosion resistance, tends to be more susceptible to dezincification, especially in acidic or saline conditions.

Common Applications of Bronze and Brass Alloys

Bronze alloys, known for their high corrosion resistance and durability, are commonly used in marine hardware, bearings, and sculptures. Brass alloys, prized for their excellent machinability and acoustic properties, find applications in musical instruments, plumbing fittings, and decorative items. Both alloys serve critical roles in industrial and artistic fields, with bronze favored for heavy-duty environments and brass preferred for aesthetic and functional versatility.

Workability and Machinability Differences

Bronze alloy, primarily composed of copper and tin, exhibits superior wear resistance but lower machinability compared to brass alloy, which consists mainly of copper and zinc. Brass alloy offers better workability due to its lower melting point and greater malleability, facilitating easier forming and shaping processes. Machining bronze requires specialized tools and slower speeds to avoid tool wear, while brass machines efficiently with standard equipment, making it preferred for intricate components.

Electrical and Thermal Conductivity

Bronze alloy, primarily composed of copper and tin, exhibits lower electrical and thermal conductivity compared to brass alloy, which consists mainly of copper and zinc. Brass alloy's superior conductivity makes it more suitable for electrical components and heat exchangers. The presence of zinc in brass enhances electron mobility, resulting in better performance in applications requiring efficient energy transfer.

Color and Aesthetic Distinctions

Bronze alloy exhibits a warm, reddish-brown hue due to its high copper and tin content, creating a classic, antique aesthetic commonly used in sculptures and architectural details. Brass alloy, characterized by a brighter, yellow-gold color from its copper and zinc composition, offers a shiny, polished appearance favored for decorative hardware and musical instruments. The distinct color differences between bronze and brass alloys influence their selection in design applications based on desired visual impact and stylistic preferences.

Cost Analysis: Bronze Alloy vs Brass Alloy

Bronze alloy generally incurs higher material costs than brass alloy due to its copper-tin composition, which typically involves more expensive raw materials. Brass alloy, composed primarily of copper and zinc, offers a cost-effective alternative with widespread availability and easier machinability, resulting in lower manufacturing expenses. For projects emphasizing budget efficiency, brass alloy often provides better economic value without compromising essential mechanical properties.

Historical Uses and Significance

Bronze alloy, primarily composed of copper and tin, has been historically significant since the Bronze Age for tools, weapons, and sculptures, facilitating advancements in ancient civilizations. Brass alloy, a mixture of copper and zinc, gained prominence later for its acoustic properties in musical instruments and corrosion resistance in decorative items and architectural elements. The distinct compositions influenced their respective uses, with bronze favored for durability and brass for aesthetic appeal and malleability.

Choosing the Right Alloy for Your Project

Bronze alloy, composed primarily of copper and tin, offers superior corrosion resistance and strength, making it ideal for heavy-duty applications like marine hardware and sculptures. Brass alloy, mainly copper and zinc, provides excellent machinability and a bright, gold-like appearance, suitable for decorative items and plumbing fittings. Selecting between bronze and brass depends on factors such as environmental exposure, mechanical strength requirements, and aesthetic preferences for your specific project.

Bronze Alloy vs Brass Alloy Infographic

materialdif.com

materialdif.com