Wrought alloys offer superior mechanical properties and enhanced durability due to their refined grain structure achieved through mechanical working processes. Cast alloys, formed by pouring molten metal into molds, generally provide more complex shapes but may exhibit porosity and lower strength compared to wrought alloys. Choosing between wrought and cast alloys depends on the specific application requirements, balancing strength, formability, and cost.

Table of Comparison

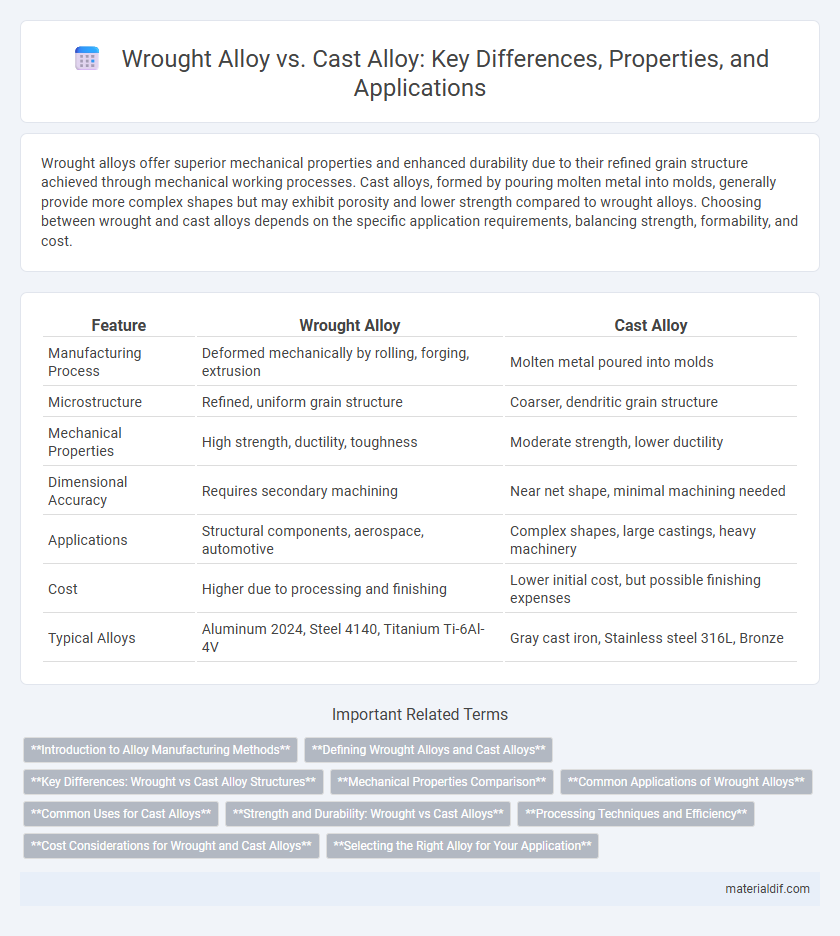

| Feature | Wrought Alloy | Cast Alloy |

|---|---|---|

| Manufacturing Process | Deformed mechanically by rolling, forging, extrusion | Molten metal poured into molds |

| Microstructure | Refined, uniform grain structure | Coarser, dendritic grain structure |

| Mechanical Properties | High strength, ductility, toughness | Moderate strength, lower ductility |

| Dimensional Accuracy | Requires secondary machining | Near net shape, minimal machining needed |

| Applications | Structural components, aerospace, automotive | Complex shapes, large castings, heavy machinery |

| Cost | Higher due to processing and finishing | Lower initial cost, but possible finishing expenses |

| Typical Alloys | Aluminum 2024, Steel 4140, Titanium Ti-6Al-4V | Gray cast iron, Stainless steel 316L, Bronze |

Introduction to Alloy Manufacturing Methods

Wrought alloys are manufactured through mechanical deformation processes such as rolling, forging, or extrusion, which refine the grain structure and enhance mechanical properties like strength and ductility. Cast alloys are produced by melting and pouring molten metal into molds, allowing complex shapes to be formed but often resulting in coarser grain structures and potential porosity. The choice between wrought and cast alloy manufacturing significantly impacts microstructure, mechanical performance, and application suitability in industries such as aerospace and automotive engineering.

Defining Wrought Alloys and Cast Alloys

Wrought alloys are metals mechanically worked by processes such as rolling, forging, or extrusion to produce desired shapes with refined grain structures and improved mechanical properties. Cast alloys are formed by melting the metal and pouring it into molds where it solidifies, allowing complex geometries but often resulting in coarser grain structures and potential porosity. The fundamental difference lies in wrought alloys being plastically deformed for enhanced strength and toughness, while cast alloys prioritize shape complexity and manufacturing ease.

Key Differences: Wrought vs Cast Alloy Structures

Wrought alloys exhibit a refined, uniform grain structure due to mechanical working processes such as rolling or forging, enhancing their strength and ductility. Cast alloys form through solidification in molds, resulting in coarser grains and potential porosity, which can reduce mechanical performance. The microstructural differences between wrought and cast alloys significantly influence their mechanical properties and suitability for various industrial applications.

Mechanical Properties Comparison

Wrought alloys exhibit superior mechanical properties compared to cast alloys due to their refined grain structure and enhanced toughness from plastic deformation processes. Cast alloys often show increased brittleness and lower tensile strength because of porosity and coarse microstructures formed during solidification. The enhanced ductility, fatigue resistance, and impact strength in wrought alloys make them ideal for high-stress applications.

Common Applications of Wrought Alloys

Wrought alloys are extensively used in aerospace components, automotive parts, and structural applications due to their superior mechanical properties and enhanced fatigue resistance compared to cast alloys. These alloys are preferred for manufacturing sheets, plates, bars, and wires where high strength, toughness, and ductility are essential. Common applications include aircraft fuselages, engine components, pressure vessels, and heavy machinery that require precise dimensional tolerances and excellent surface finishes.

Common Uses for Cast Alloys

Cast alloys are primarily utilized in automotive engine blocks, pump housings, and intricate machine components due to their ability to form complex shapes with high dimensional accuracy. These alloys offer excellent fluidity and reduced grain size, making them ideal for mass production of parts requiring detailed geometries and consistent mechanical properties. Cast alloys also find common applications in aerospace components, valves, and heavy-duty equipment where strength and thermal stability are critical.

Strength and Durability: Wrought vs Cast Alloys

Wrought alloys exhibit superior strength and durability due to their refined grain structures achieved through mechanical working processes like rolling and forging, which enhance resistance to fatigue and impact. Cast alloys often contain larger, irregular grain structures and porosity from solidification, resulting in lower tensile strength and increased brittleness compared to wrought counterparts. This fundamental difference makes wrought alloys ideal for high-stress applications demanding exceptional toughness and longevity.

Processing Techniques and Efficiency

Wrought alloys undergo mechanical processing methods such as rolling, forging, and extrusion, which enhance grain structure uniformity and improve mechanical properties, resulting in higher strength and ductility. Cast alloys are shaped by melting and pouring into molds, enabling complex geometries but often leading to coarser microstructures and potential porosity, which can reduce mechanical performance. Wrought alloy processing generally demands more energy and time but yields superior efficiency in producing components with consistent mechanical properties and tighter tolerances.

Cost Considerations for Wrought and Cast Alloys

Wrought alloys generally incur higher production costs due to extensive mechanical working and machining processes, which enhance strength and ductility but increase labor and energy expenses. Cast alloys offer cost efficiency with lower manufacturing complexity by melting and pouring metal into molds, making them ideal for large and intricate shapes with moderate mechanical properties. Material waste and tooling costs also differ, with wrought alloys producing less scrap but requiring more expensive equipment, while cast alloys benefit from economies of scale in mold production and bulk melting.

Selecting the Right Alloy for Your Application

Selecting the right alloy for your application depends on factors such as mechanical strength, corrosion resistance, and manufacturing process requirements. Wrought alloys offer superior toughness and machinability due to their grain structure refinement achieved through rolling or forging, making them ideal for high-stress applications. Cast alloys provide complex shapes with lower production costs but often have inferior mechanical properties and higher porosity, suitable for applications where intricate geometry is prioritized over strength.

Wrought Alloy vs Cast Alloy Infographic

materialdif.com

materialdif.com