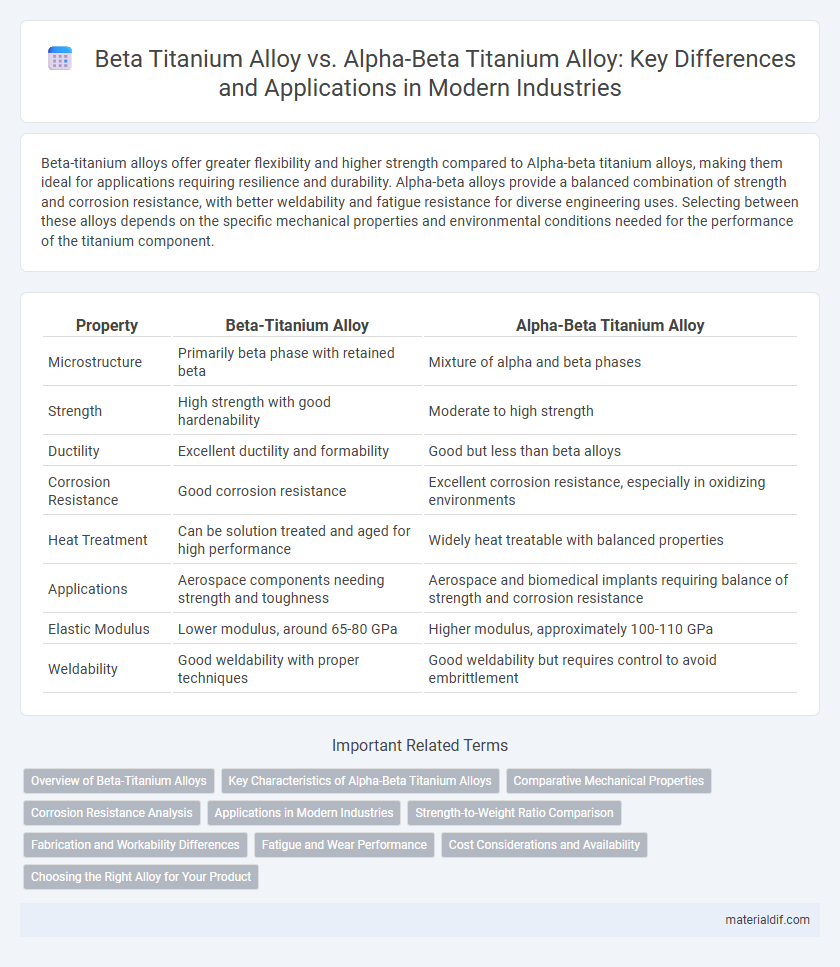

Beta-titanium alloys offer greater flexibility and higher strength compared to Alpha-beta titanium alloys, making them ideal for applications requiring resilience and durability. Alpha-beta alloys provide a balanced combination of strength and corrosion resistance, with better weldability and fatigue resistance for diverse engineering uses. Selecting between these alloys depends on the specific mechanical properties and environmental conditions needed for the performance of the titanium component.

Table of Comparison

| Property | Beta-Titanium Alloy | Alpha-Beta Titanium Alloy |

|---|---|---|

| Microstructure | Primarily beta phase with retained beta | Mixture of alpha and beta phases |

| Strength | High strength with good hardenability | Moderate to high strength |

| Ductility | Excellent ductility and formability | Good but less than beta alloys |

| Corrosion Resistance | Good corrosion resistance | Excellent corrosion resistance, especially in oxidizing environments |

| Heat Treatment | Can be solution treated and aged for high performance | Widely heat treatable with balanced properties |

| Applications | Aerospace components needing strength and toughness | Aerospace and biomedical implants requiring balance of strength and corrosion resistance |

| Elastic Modulus | Lower modulus, around 65-80 GPa | Higher modulus, approximately 100-110 GPa |

| Weldability | Good weldability with proper techniques | Good weldability but requires control to avoid embrittlement |

Overview of Beta-Titanium Alloys

Beta-titanium alloys exhibit a fully beta-phase microstructure at room temperature, offering superior strength and exceptional corrosion resistance compared to alpha-beta titanium alloys, which contain both alpha and beta phases. These alloys feature enhanced formability and heat treatability, enabling precise mechanical property adjustments for aerospace and biomedical applications. Key beta-titanium alloys include Ti-15V-3Cr-3Al-3Sn and Ti-13V-11Cr-3Al, known for their high fracture toughness and improved fatigue performance.

Key Characteristics of Alpha-Beta Titanium Alloys

Alpha-beta titanium alloys exhibit a balanced combination of strength, ductility, and corrosion resistance due to their dual-phase microstructure consisting of both alpha and beta phases. These alloys offer excellent weldability and are commonly used in aerospace, automotive, and biomedical applications where high performance and toughness are required. The ability to tailor mechanical properties through heat treatment enhances their versatility compared to beta-titanium alloys, which predominantly feature higher strength but lower ductility.

Comparative Mechanical Properties

Beta-titanium alloys exhibit higher strength and improved fatigue resistance compared to alpha-beta titanium alloys, making them ideal for aerospace and biomedical applications requiring superior mechanical performance. Alpha-beta titanium alloys offer better weldability and corrosion resistance while maintaining good strength and toughness, suitable for general engineering uses. The enhanced ductility and lower modulus of elasticity in beta-titanium alloys contribute to reduced stress shielding in implant applications, surpassing the mechanical adaptability of alpha-beta alloys.

Corrosion Resistance Analysis

Beta-titanium alloys exhibit superior corrosion resistance compared to alpha-beta titanium alloys due to their homogeneous microstructure and higher beta phase content, which enhances passivation and reduces susceptibility to localized corrosion. The increased molybdenum and vanadium alloying elements in beta-titanium contribute to improved resistance against chloride-induced pitting and crevice corrosion. In contrast, alpha-beta titanium alloys, with mixed phases, often display varied corrosion behavior that can lead to galvanic corrosion between alpha and beta regions under aggressive environments.

Applications in Modern Industries

Beta-titanium alloys offer excellent strength, corrosion resistance, and formability, making them ideal for aerospace components, medical implants, and high-performance automotive parts. Alpha-beta titanium alloys combine the benefits of both alpha and beta phases, providing superior fatigue resistance and weldability, which suits them for aircraft structural components, chemical processing equipment, and marine applications. Both alloy types cater to modern industries demanding lightweight, durable, and corrosion-resistant materials for enhanced performance and longevity.

Strength-to-Weight Ratio Comparison

Beta-titanium alloys exhibit a higher strength-to-weight ratio compared to alpha-beta titanium alloys, making them ideal for aerospace and automotive applications where lightweight durability is critical. The microstructure of beta-titanium alloys allows for enhanced work hardening and better strain hardening capabilities, resulting in superior tensile strength without significant weight increase. Alpha-beta titanium alloys, while offering good strength and corrosion resistance, generally have a lower strength-to-weight ratio due to their mixed alpha and beta phase compositions.

Fabrication and Workability Differences

Beta-titanium alloys exhibit superior formability and higher strength during fabrication compared to alpha-beta titanium alloys, making them ideal for complex structural components requiring extensive deformation processes. Alpha-beta titanium alloys combine good weldability with moderate workability, suitable for applications needing a balance between strength and ease of manufacturing. The fabrication of beta-titanium alloys often demands precise temperature control during heat treatment to enhance ductility and mechanical performance, whereas alpha-beta alloys allow more flexible processing conditions with diverse welding techniques.

Fatigue and Wear Performance

Beta-titanium alloys exhibit superior fatigue resistance and enhanced wear performance due to their homogeneous microstructure and higher strength compared to alpha-beta titanium alloys. The increased fatigue life in beta-titanium alloys results from their ability to inhibit crack initiation and propagation under cyclic loading conditions. Wear resistance improvements in beta-titanium alloys stem from their denser phase distribution, which reduces material removal and surface degradation during mechanical contact.

Cost Considerations and Availability

Beta-titanium alloys tend to be more expensive than alpha-beta titanium alloys due to their complex production processes and higher raw material costs. Alpha-beta titanium alloys, such as Ti-6Al-4V, are more widely available and benefit from established supply chains, making them more cost-effective for large-scale manufacturing. The broader industrial adoption of alpha-beta alloys also ensures easier procurement and reduced lead times compared to the more specialized beta alloys.

Choosing the Right Alloy for Your Product

Beta-titanium alloys exhibit higher strength and superior corrosion resistance compared to Alpha-beta titanium alloys, making them ideal for high-performance aerospace and medical applications. Alpha-beta titanium alloys offer better weldability and formability, which is crucial for complex shapes and cost-effective manufacturing in automotive and structural components. Selecting the right alloy depends on balancing mechanical properties, fabrication requirements, and environmental resistance to ensure optimal product performance and longevity.

Beta-titanium alloy vs Alpha-beta titanium alloy Infographic

materialdif.com

materialdif.com