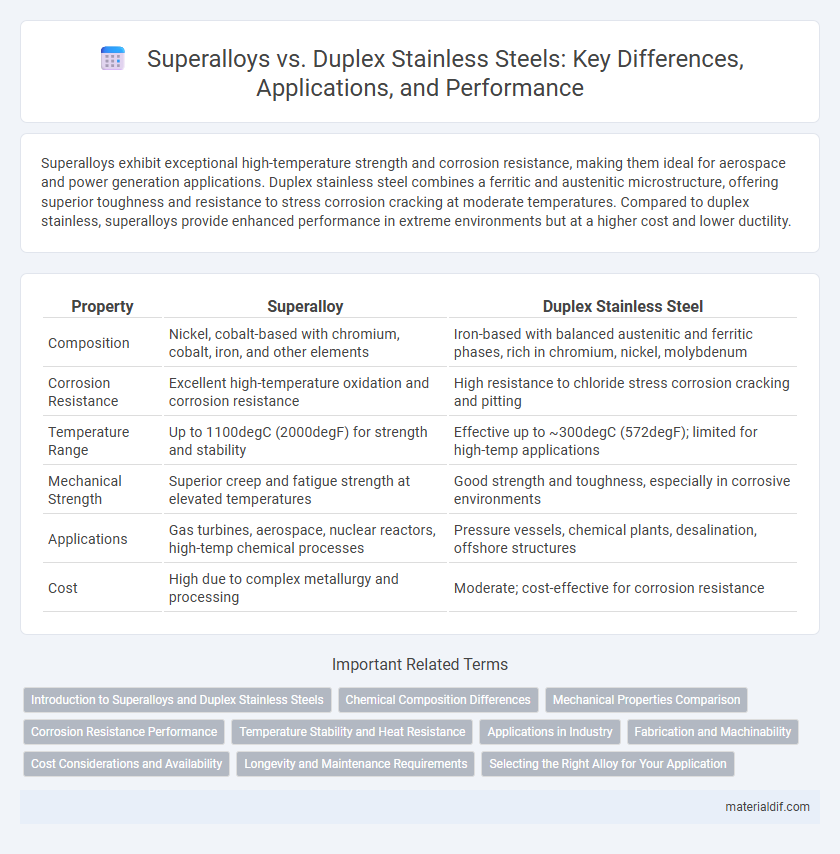

Superalloys exhibit exceptional high-temperature strength and corrosion resistance, making them ideal for aerospace and power generation applications. Duplex stainless steel combines a ferritic and austenitic microstructure, offering superior toughness and resistance to stress corrosion cracking at moderate temperatures. Compared to duplex stainless, superalloys provide enhanced performance in extreme environments but at a higher cost and lower ductility.

Table of Comparison

| Property | Superalloy | Duplex Stainless Steel |

|---|---|---|

| Composition | Nickel, cobalt-based with chromium, cobalt, iron, and other elements | Iron-based with balanced austenitic and ferritic phases, rich in chromium, nickel, molybdenum |

| Corrosion Resistance | Excellent high-temperature oxidation and corrosion resistance | High resistance to chloride stress corrosion cracking and pitting |

| Temperature Range | Up to 1100degC (2000degF) for strength and stability | Effective up to ~300degC (572degF); limited for high-temp applications |

| Mechanical Strength | Superior creep and fatigue strength at elevated temperatures | Good strength and toughness, especially in corrosive environments |

| Applications | Gas turbines, aerospace, nuclear reactors, high-temp chemical processes | Pressure vessels, chemical plants, desalination, offshore structures |

| Cost | High due to complex metallurgy and processing | Moderate; cost-effective for corrosion resistance |

Introduction to Superalloys and Duplex Stainless Steels

Superalloys, primarily based on nickel, cobalt, or iron, are engineered for exceptional mechanical strength, resistance to thermal creep deformation, and oxidation at high temperatures, making them ideal for aerospace and power generation applications. Duplex stainless steels exhibit a balanced microstructure of austenite and ferrite, offering superior corrosion resistance and enhanced strength compared to standard stainless steels, widely used in chemical processing and marine environments. Both materials serve critical roles where durability under extreme conditions is paramount, but superalloys focus more on high-temperature performance while duplex stainless steels emphasize corrosion resistance and toughness.

Chemical Composition Differences

Superalloys primarily consist of high concentrations of nickel, cobalt, and chromium, with additions of elements like molybdenum, aluminum, and titanium enhancing their high-temperature strength and corrosion resistance. Duplex stainless steels feature a balanced chemical composition of approximately 20-30% chromium, 4-7% nickel, and 1.5-3% molybdenum, combining ferritic and austenitic phases for improved mechanical properties and corrosion resistance in chloride environments. The key difference lies in superalloys' emphasis on nickel and cobalt content for extreme temperature applications, while duplex stainless steels optimize chromium and molybdenum to resist stress corrosion cracking and improve durability.

Mechanical Properties Comparison

Superalloys exhibit superior mechanical properties such as exceptional tensile strength, creep resistance, and high-temperature stability, making them ideal for aerospace and turbine engine components. Duplex stainless steels provide a balanced combination of high strength and excellent corrosion resistance due to their dual-phase microstructure, suitable for chemical processing and marine applications. While superalloys outperform duplex stainless steels in extreme temperature conditions, duplex grades offer better resistance to stress corrosion cracking and fatigue in moderate environments.

Corrosion Resistance Performance

Superalloys exhibit exceptional corrosion resistance in extreme environments due to their high nickel and chromium content, making them ideal for high-temperature, oxidative, and acidic conditions. Duplex stainless steels combine austenitic and ferritic phases, offering superior resistance to stress corrosion cracking and pitting, especially in chloride-rich environments. Corrosion resistance of superalloys generally surpasses duplex stainless steels at elevated temperatures, while duplex steels provide cost-effective protection in moderate corrosive settings.

Temperature Stability and Heat Resistance

Superalloys exhibit exceptional temperature stability and heat resistance, maintaining mechanical strength and oxidation resistance at temperatures exceeding 1000degC, making them ideal for turbine engines and aerospace applications. Duplex stainless steels offer moderate heat resistance with temperature stability up to approximately 300-400degC, benefiting corrosion resistance but limiting high-temperature applications. The superior performance of superalloys in extreme thermal environments outweighs the duplex stainless advantage in corrosion resistance for high-temperature use cases.

Applications in Industry

Superalloys excel in high-temperature applications such as aerospace turbine engines and power plant components due to their exceptional strength and oxidation resistance. Duplex stainless steels are favored in chemical processing, marine environments, and oil and gas industries for their superior corrosion resistance and high mechanical strength. Both materials are critical in industries requiring reliability under extreme conditions, with superalloys dominating thermal stress environments and duplex stainless steels preferred for corrosive service.

Fabrication and Machinability

Superalloys exhibit superior high-temperature strength and corrosion resistance but require specialized fabrication techniques such as precision casting, hot working, and heat treatment due to their complex microstructure. Duplex stainless steels offer enhanced machinability and weldability because of their balanced austenitic-ferritic phases, enabling cost-effective fabrication with conventional methods like forging and machining. The choice between superalloys and duplex stainless steels depends on the application's thermal and mechanical demands, where fabrication complexity and machinability are critical factors.

Cost Considerations and Availability

Superalloys generally incur higher costs due to their complex manufacturing processes and expensive raw materials like nickel and cobalt, whereas duplex stainless steels offer a more cost-effective solution with lower nickel content and simpler fabrication requirements. Availability of superalloys can be limited as they are often produced in specialized facilities with longer lead times, while duplex stainless steels enjoy broader market availability and quicker procurement due to their widespread industrial use. Cost-effectiveness and accessibility make duplex stainless steels preferable for large-scale applications where budget constraints and supply reliability are critical.

Longevity and Maintenance Requirements

Superalloys exhibit superior longevity due to exceptional corrosion resistance and high-temperature strength, making them ideal for demanding environments like aerospace and power generation. Duplex stainless steels offer a balanced performance with good corrosion resistance and moderate maintenance needs, especially in chemical processing and marine applications. Maintenance requirements for superalloys are minimal but often costly, while duplex stainless steels require more frequent inspections yet allow easier and less expensive upkeep.

Selecting the Right Alloy for Your Application

Superalloys offer exceptional resistance to high temperatures and corrosion, making them ideal for aerospace and power generation applications where strength retention under extreme conditions is critical. Duplex stainless steels combine excellent mechanical properties with superior resistance to stress corrosion cracking, suitable for chemical processing and marine environments. Selecting the right alloy involves evaluating temperature limits, corrosion resistance requirements, mechanical strength, and cost-effectiveness tailored to the specific operational environment.

Superalloy vs Duplex Stainless Infographic

materialdif.com

materialdif.com