Ferritic stainless steel offers superior corrosion resistance in chloride environments and better stress corrosion cracking resistance compared to austenitic stainless steel, making it ideal for automotive exhaust systems and industrial applications. Austenitic stainless steel, known for its excellent formability, high toughness at low temperatures, and outstanding resistance to oxidation, is widely used in food processing, chemical, and architectural industries. While ferritic grades are magnetic and less expensive, austenitic stainless steels provide greater versatility and enhanced mechanical properties for a broader range of demanding applications.

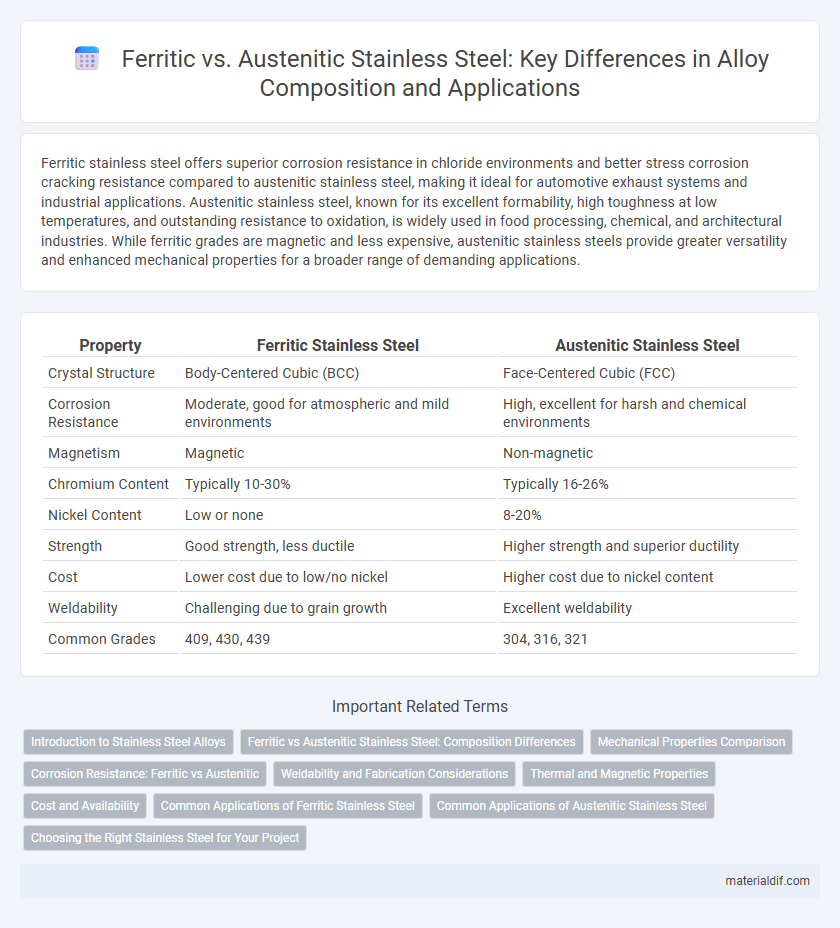

Table of Comparison

| Property | Ferritic Stainless Steel | Austenitic Stainless Steel |

|---|---|---|

| Crystal Structure | Body-Centered Cubic (BCC) | Face-Centered Cubic (FCC) |

| Corrosion Resistance | Moderate, good for atmospheric and mild environments | High, excellent for harsh and chemical environments |

| Magnetism | Magnetic | Non-magnetic |

| Chromium Content | Typically 10-30% | Typically 16-26% |

| Nickel Content | Low or none | 8-20% |

| Strength | Good strength, less ductile | Higher strength and superior ductility |

| Cost | Lower cost due to low/no nickel | Higher cost due to nickel content |

| Weldability | Challenging due to grain growth | Excellent weldability |

| Common Grades | 409, 430, 439 | 304, 316, 321 |

Introduction to Stainless Steel Alloys

Ferritic stainless steel contains high chromium content (10.5-30%) and low carbon, offering excellent corrosion resistance and magnetic properties, primarily used in automotive and industrial applications. Austenitic stainless steel, composed mainly of iron with 16-26% chromium and 6-22% nickel, provides superior corrosion resistance, ductility, and non-magnetic characteristics, commonly utilized in kitchen equipment and chemical processing. Both alloys offer distinct mechanical and chemical advantages tailored to specific environmental and structural requirements in stainless steel applications.

Ferritic vs Austenitic Stainless Steel: Composition Differences

Ferritic stainless steel primarily contains 10.5% to 30% chromium with minimal or no nickel, resulting in a body-centered cubic (BCC) crystal structure that enhances magnetic properties and corrosion resistance in chloride environments. Austenitic stainless steel typically includes 16% to 26% chromium and 6% to 22% nickel, featuring a face-centered cubic (FCC) structure that offers superior toughness, ductility, and resistance to oxidation and various chemicals. The absence of nickel in ferritic grades makes them more cost-effective but less formable compared to the highly ductile, nickel-enriched austenitic alloys.

Mechanical Properties Comparison

Ferritic stainless steel exhibits higher magnetic permeability and better resistance to stress corrosion cracking compared to austenitic stainless steel, making it suitable for applications requiring moderate strength and good ductility. Austenitic stainless steel offers superior tensile strength, excellent toughness at low temperatures, and enhanced formability due to its face-centered cubic crystal structure. The mechanical properties of austenitic grades like 304 or 316 typically include yield strengths around 215-290 MPa and elongation percentages exceeding 40%, whereas ferritic grades such as 430 provide yield strengths closer to 200 MPa with lower ductility.

Corrosion Resistance: Ferritic vs Austenitic

Ferritic stainless steel exhibits moderate corrosion resistance, particularly effective against stress corrosion cracking and chloride-induced corrosion due to its high chromium content and low nickel levels. Austenitic stainless steel offers superior corrosion resistance in highly corrosive environments, attributed to its higher nickel and chromium content, making it ideal for acidic and marine applications. The choice between ferritic and austenitic types depends on the specific exposure conditions, where austenitic grades generally withstand a broader range of aggressive chemicals and temperatures.

Weldability and Fabrication Considerations

Ferritic stainless steel offers superior weldability due to its lower thermal expansion and higher thermal conductivity, reducing distortion and cracking risks during fabrication. Austenitic stainless steel, while more prone to weld-related issues like sensitization and grain growth, benefits from its excellent ductility and toughness, facilitating complex fabrication and forming processes. Selecting the appropriate grade depends on balancing these factors with application-specific corrosion resistance and mechanical requirements.

Thermal and Magnetic Properties

Ferritic stainless steel exhibits superior thermal conductivity and lower coefficient of thermal expansion compared to austenitic stainless steel, making it ideal for applications requiring efficient heat dissipation. Ferritic grades are magnetic due to their body-centered cubic (BCC) crystal structure, whereas austenitic stainless steel, with a face-centered cubic (FCC) structure, is generally non-magnetic. These distinct thermal and magnetic properties influence the selection of stainless steel types in fields such as automotive exhaust systems and heat exchangers.

Cost and Availability

Ferritic stainless steel generally offers lower cost and better availability compared to austenitic stainless steel due to its simpler chemical composition and lower nickel content. Austenitic stainless steel, rich in nickel and chromium, tends to be more expensive and less readily available because of fluctuating raw material prices and higher demand in specialized applications. Cost-efficiency and supply stability make ferritic grades preferable for large-scale industrial use, while austenitic grades dominate in corrosion-resistant environments despite their premium price.

Common Applications of Ferritic Stainless Steel

Ferritic stainless steel is widely used in automotive exhaust systems, kitchen utensils, and architectural panels due to its excellent corrosion resistance and magnetic properties. It is preferred for industrial equipment, such as heat exchangers and chemical processing tanks, where moderate strength and good oxidation resistance are required. Ferritic grades like 409 and 430 stainless steel offer cost-effective solutions for applications exposed to mild corrosive environments.

Common Applications of Austenitic Stainless Steel

Austenitic stainless steel is widely used in food processing equipment, chemical plants, and architectural structures due to its excellent corrosion resistance and high ductility. It is commonly found in kitchen utensils, medical instruments, and automotive exhaust systems, offering superior durability in harsh environments. The alloy's non-magnetic properties and ability to withstand extreme temperatures make it essential for cryogenic and high-temperature applications.

Choosing the Right Stainless Steel for Your Project

Ferritic stainless steel offers excellent corrosion resistance and magnetic properties, making it ideal for automotive exhaust systems and industrial equipment requiring strength at moderate temperatures. Austenitic stainless steel provides superior corrosion resistance, high ductility, and non-magnetic characteristics, preferred for chemical processing, food handling, and architectural applications. Selecting between ferritic and austenitic stainless steel depends on factors like corrosion environment, mechanical stress, temperature exposure, and cost efficiency.

Ferritic stainless steel vs Austenitic stainless steel Infographic

materialdif.com

materialdif.com