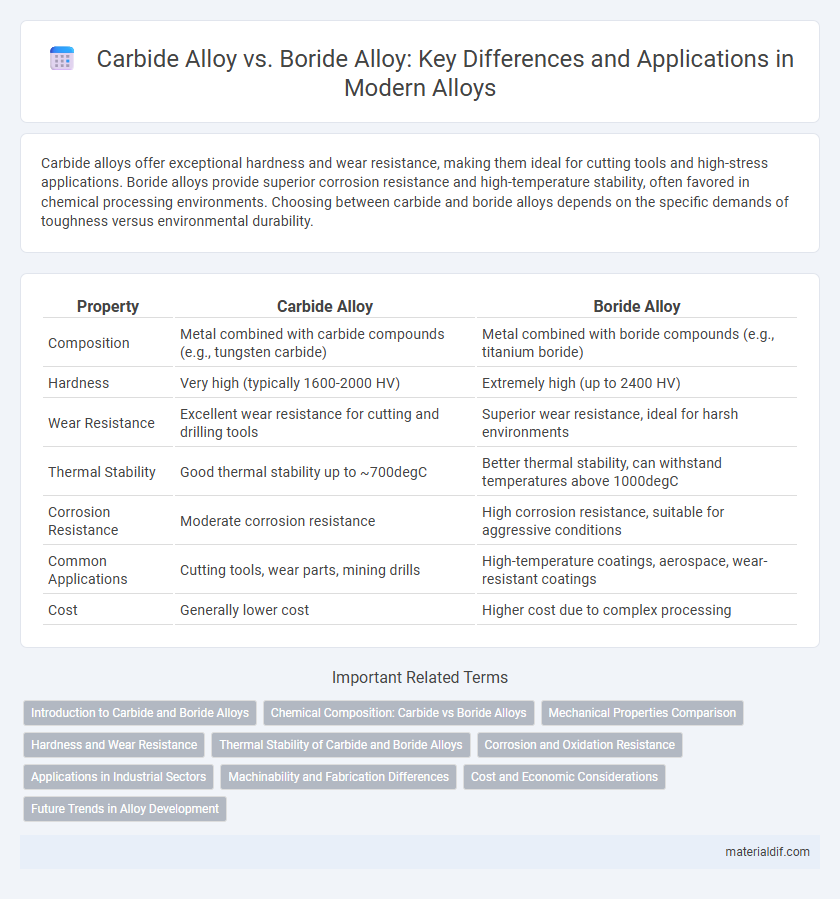

Carbide alloys offer exceptional hardness and wear resistance, making them ideal for cutting tools and high-stress applications. Boride alloys provide superior corrosion resistance and high-temperature stability, often favored in chemical processing environments. Choosing between carbide and boride alloys depends on the specific demands of toughness versus environmental durability.

Table of Comparison

| Property | Carbide Alloy | Boride Alloy |

|---|---|---|

| Composition | Metal combined with carbide compounds (e.g., tungsten carbide) | Metal combined with boride compounds (e.g., titanium boride) |

| Hardness | Very high (typically 1600-2000 HV) | Extremely high (up to 2400 HV) |

| Wear Resistance | Excellent wear resistance for cutting and drilling tools | Superior wear resistance, ideal for harsh environments |

| Thermal Stability | Good thermal stability up to ~700degC | Better thermal stability, can withstand temperatures above 1000degC |

| Corrosion Resistance | Moderate corrosion resistance | High corrosion resistance, suitable for aggressive conditions |

| Common Applications | Cutting tools, wear parts, mining drills | High-temperature coatings, aerospace, wear-resistant coatings |

| Cost | Generally lower cost | Higher cost due to complex processing |

Introduction to Carbide and Boride Alloys

Carbide alloys consist primarily of metal carbides known for their exceptional hardness and wear resistance, often used in cutting tools and industrial machinery. Boride alloys contain metal borides that provide high-temperature strength and corrosion resistance, making them ideal for aerospace and defense applications. Both alloys combine metal matrices with ceramic properties, enhancing durability in extreme conditions.

Chemical Composition: Carbide vs Boride Alloys

Carbide alloys primarily consist of carbon combined with metals such as tungsten, titanium, or chromium, forming hard, wear-resistant carbides. Boride alloys contain boron bonded with metals like iron, cobalt, or nickel, resulting in compounds with exceptional hardness and high-temperature stability. The chemical composition of carbide alloys emphasizes carbon-metal bonds for abrasion resistance, while boride alloys rely on boron-metal bonds to enhance thermal and chemical resilience.

Mechanical Properties Comparison

Carbide alloys exhibit superior hardness and wear resistance due to their dense carbide precipitates, making them ideal for cutting tools and wear-resistant applications. Boride alloys offer enhanced toughness and impact resistance, attributed to their boride phase distribution, which improves fracture toughness under high-stress conditions. Mechanical property tests reveal carbide alloys excel in compressive strength, while boride alloys provide better ductility and thermal stability.

Hardness and Wear Resistance

Carbide alloys exhibit superior hardness due to the presence of tungsten carbide particles, making them highly resistant to abrasive wear and suitable for cutting tools and wear-resistant coatings. Boride alloys, reinforced with metal borides such as titanium boride, offer enhanced wear resistance combined with improved toughness and thermal stability, ideal for heavy-duty applications and high-temperature environments. While carbide alloys lead in hardness, boride alloys provide a balanced performance with better impact resistance and prolonged service life under cyclic stress.

Thermal Stability of Carbide and Boride Alloys

Carbide alloys exhibit superior thermal stability due to their high melting points and robust crystal structures, which enhance resistance to deformation and oxidation at elevated temperatures. Boride alloys demonstrate even greater thermal stability, often surpassing carbides, as borides form extremely hard, refractory phases that maintain strength and hardness under extreme heat. Both alloys are critical in high-temperature applications, but boride alloys are preferred when maximum thermal stability and wear resistance are required.

Corrosion and Oxidation Resistance

Carbide alloys exhibit superior corrosion resistance due to the stable carbide phases that form protective barriers against aggressive environments, whereas boride alloys often demonstrate enhanced oxidation resistance attributed to the formation of dense, adherent boride scales that prevent oxygen diffusion. In high-temperature applications, carbide alloys maintain structural integrity by resisting corrosive attack, while boride alloys excel by minimizing oxidation-induced degradation. Selecting between carbide and boride alloys depends on the specific environmental conditions, with carbide alloys favored in chemically corrosive mediums and boride alloys preferred for oxidation-prone atmospheres.

Applications in Industrial Sectors

Carbide alloys excel in cutting tools, wear-resistant parts, and mining equipment due to their exceptional hardness and thermal stability. Boride alloys offer superior corrosion resistance and high-temperature strength, making them ideal for aerospace components, chemical processing machinery, and turbine blades. Both alloys find critical applications in manufacturing industries requiring durability under extreme mechanical and thermal conditions.

Machinability and Fabrication Differences

Carbide alloys exhibit superior hardness and wear resistance but pose significant challenges in machinability, often requiring specialized tooling and slower cutting speeds to prevent tool wear. Boride alloys, while also hard, typically offer improved machinability due to their relatively lower brittleness and better thermal conductivity, facilitating faster fabrication and reduced tooling costs. These differences in machinability and fabrication efficiency make carbide alloys more suitable for high-wear applications, whereas boride alloys are preferred when ease of manufacturing and cost-effectiveness are critical.

Cost and Economic Considerations

Carbide alloys generally offer a lower initial cost compared to boride alloys, making them more accessible for widespread industrial applications. Boride alloys, while typically more expensive, provide superior hardness and wear resistance, which can reduce long-term maintenance and replacement expenses. Choosing between carbide and boride alloys depends on balancing upfront material costs with the projected lifecycle and performance benefits specific to the application's demands.

Future Trends in Alloy Development

Future trends in alloy development emphasize enhancing wear resistance and thermal stability by optimizing carbide and boride alloy compositions. Carbide alloys, known for their exceptional hardness and toughness, are evolving with nanostructured carbides to improve durability in extreme environments. Boride alloys are gaining attention for their superior high-temperature oxidation resistance, making them ideal candidates for aerospace and energy applications.

Carbide Alloy vs Boride Alloy Infographic

materialdif.com

materialdif.com