Alloy pet materials exhibit excellent weldability due to their chemical composition, ensuring strong, durable joints in fabrication processes. However, their machinability can be challenging, requiring specialized tools and techniques to achieve precise cuts without compromising material integrity. Balancing weldability and machinability is essential for optimizing manufacturing efficiency and product performance in alloy pet applications.

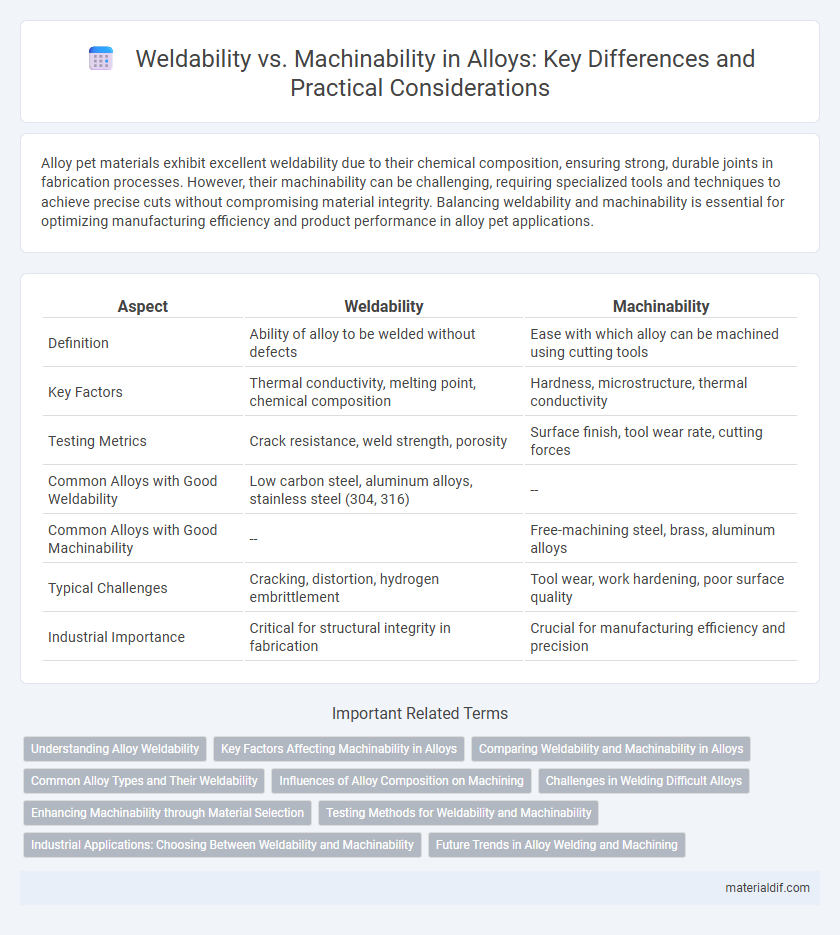

Table of Comparison

| Aspect | Weldability | Machinability |

|---|---|---|

| Definition | Ability of alloy to be welded without defects | Ease with which alloy can be machined using cutting tools |

| Key Factors | Thermal conductivity, melting point, chemical composition | Hardness, microstructure, thermal conductivity |

| Testing Metrics | Crack resistance, weld strength, porosity | Surface finish, tool wear rate, cutting forces |

| Common Alloys with Good Weldability | Low carbon steel, aluminum alloys, stainless steel (304, 316) | -- |

| Common Alloys with Good Machinability | -- | Free-machining steel, brass, aluminum alloys |

| Typical Challenges | Cracking, distortion, hydrogen embrittlement | Tool wear, work hardening, poor surface quality |

| Industrial Importance | Critical for structural integrity in fabrication | Crucial for manufacturing efficiency and precision |

Understanding Alloy Weldability

Weldability in alloys refers to the material's ability to be joined by welding without compromising structural integrity, influenced by factors such as chemical composition, thermal conductivity, and melting point. Understanding alloy weldability involves analyzing its susceptibility to defects like cracking, porosity, and distortion during welding processes, which varies significantly between ferrous and non-ferrous alloys. Machinability, while related to ease of shaping and finishing, does not directly predict weldability, as alloys optimized for machining may require specialized welding techniques to ensure strong and defect-free joints.

Key Factors Affecting Machinability in Alloys

Key factors affecting machinability in alloys include composition, microstructure, and hardness, which influence tool wear and surface finish quality. Elements such as sulfur, lead, and phosphorus can enhance machinability by improving chip breaking and reducing built-up edge formation during cutting. Heat treatment processes alter grain size and phase distribution, directly impacting the alloy's machinability and overall performance in manufacturing applications.

Comparing Weldability and Machinability in Alloys

Weldability in alloys refers to the ease with which different metals can be joined without defects such as cracking or porosity, often influenced by composition, thermal conductivity, and grain structure. Machinability, on the other hand, measures how readily an alloy can be cut, shaped, or finished using machining processes, depending on factors like hardness, tensile strength, and thermal properties. Comparing these properties reveals that alloys with high weldability, such as low-carbon steels, may exhibit lower machinability, while alloys optimized for machining, like free-machining stainless steels, often require specific precautions during welding to prevent weakening or distortion.

Common Alloy Types and Their Weldability

Common alloy types such as carbon steel, stainless steel, and aluminum alloys exhibit varying weldability characteristics due to their distinct chemical compositions and microstructures. Carbon steel offers excellent weldability with minimal preheating, while stainless steel requires careful control of heat input to prevent sensitization and corrosion. Aluminum alloys generally present challenges in weldability because of their high thermal conductivity and oxidation tendencies, necessitating specialized welding techniques.

Influences of Alloy Composition on Machining

Alloy composition significantly influences machining by affecting hardness, strength, and thermal conductivity, which determine tool wear and cutting efficiency. Elements like chromium, nickel, and molybdenum enhance corrosion resistance but can reduce machinability due to increased hardness. Conversely, lead and sulfur additions improve machinability by promoting chip breakage and reducing friction during cutting processes.

Challenges in Welding Difficult Alloys

Welding difficult alloys presents significant challenges due to their inherent metallurgical properties, including high thermal conductivity and susceptibility to cracking. These alloys often require precise control of heat input and specialized filler materials to maintain structural integrity and avoid defects. Machinability issues further complicate welding, as surface hardness and work hardening can reduce weld quality and increase production time.

Enhancing Machinability through Material Selection

Enhancing machinability in alloys requires careful material selection emphasizing low-hardness and uniform microstructure to reduce tool wear and improve surface finish. Alloys with optimized chemical compositions, such as free-machining steels containing sulfur or lead, provide better chip breaking and lower cutting forces. Prioritizing machinability over weldability often involves choosing alloys with minimal alloying elements that cause brittleness or hot cracking during welding.

Testing Methods for Weldability and Machinability

Testing methods for weldability often include bead-on-plate welding, tensile testing on welded joints, and microstructural analysis to evaluate weld integrity and susceptibility to cracking. Machinability testing involves measuring parameters such as cutting forces, tool wear rates, surface finish, and chip formation during standardized machining processes like turning, milling, or drilling. Both testing approaches rely on precise control of processing variables and metallurgical examination to optimize alloy selection for specific manufacturing requirements.

Industrial Applications: Choosing Between Weldability and Machinability

In industrial applications, selecting alloys with superior weldability ensures robust joint strength and minimizes defects in fabrication processes such as pipeline construction and automotive manufacturing. Conversely, alloys with high machinability reduce tool wear and cycle time, making them ideal for precision components in aerospace and electronics industries. Balancing weldability and machinability depends on the end-use requirements, production efficiency, and cost-effectiveness of the alloy in specific manufacturing environments.

Future Trends in Alloy Welding and Machining

Advancements in additive manufacturing and machine learning are driving future trends in alloy welding and machining, enhancing weldability through real-time defect detection and adaptive process control. Emerging alloys with refined microstructures improve machinability by reducing tool wear and increasing precision in complex geometries. Integration of smart sensors and AI-driven optimization is set to revolutionize alloy processing by minimizing errors and maximizing efficiency in industrial applications.

Weldability vs Machinability Infographic

materialdif.com

materialdif.com