Alloy casting involves pouring molten metal into a mold to create complex shapes with precise dimensions, making it ideal for intricate designs and lower production volumes. Forging shapes metal through compressive forces, enhancing its strength and grain structure, which results in superior mechanical properties suited for high-stress applications. Choosing between casting and forging depends on the required strength, complexity, and cost-efficiency of the final alloy product.

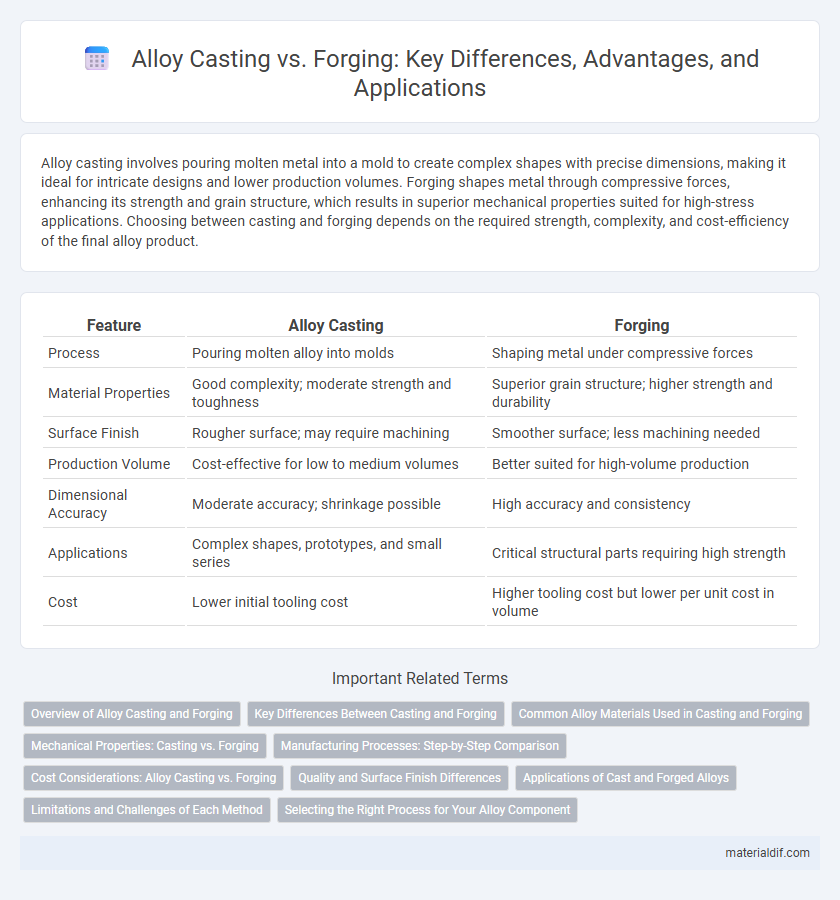

Table of Comparison

| Feature | Alloy Casting | Forging |

|---|---|---|

| Process | Pouring molten alloy into molds | Shaping metal under compressive forces |

| Material Properties | Good complexity; moderate strength and toughness | Superior grain structure; higher strength and durability |

| Surface Finish | Rougher surface; may require machining | Smoother surface; less machining needed |

| Production Volume | Cost-effective for low to medium volumes | Better suited for high-volume production |

| Dimensional Accuracy | Moderate accuracy; shrinkage possible | High accuracy and consistency |

| Applications | Complex shapes, prototypes, and small series | Critical structural parts requiring high strength |

| Cost | Lower initial tooling cost | Higher tooling cost but lower per unit cost in volume |

Overview of Alloy Casting and Forging

Alloy casting involves pouring molten metal into molds to achieve complex shapes and detailed features with excellent dimensional accuracy, ideal for intricate components. Forging reshapes solid metal using compressive forces, resulting in improved mechanical properties and grain structure, suitable for high-strength applications. Both processes enhance alloy characteristics but differ significantly in production techniques, material properties, and application suitability.

Key Differences Between Casting and Forging

Alloy casting involves pouring molten metal into a mold to shape complex geometries, offering high design flexibility and suitability for large, intricate parts. Forging applies compressive forces to shape metal, enhancing mechanical properties like strength and grain structure through deformation. Key differences include casting's ability to produce intricate shapes at lower strength versus forging's superior strength and fatigue resistance but limited geometric complexity.

Common Alloy Materials Used in Casting and Forging

Common alloy materials used in casting include aluminum alloys, cast iron, and bronze, prized for their excellent fluidity and ability to form complex shapes. In forging, steel alloys, particularly carbon steel and stainless steel, dominate due to their superior strength and ductility after deformation. Copper and nickel alloys are also favored in both processes for their corrosion resistance and thermal properties.

Mechanical Properties: Casting vs. Forging

Forged alloys exhibit superior mechanical properties compared to cast alloys, including higher tensile strength, improved fatigue resistance, and enhanced ductility due to the refined grain structure formed under compressive forces. Cast alloys often contain internal porosities and microstructural defects, leading to lower impact toughness and reduced fatigue life. The forging process aligns the metal grains, resulting in increased uniformity and mechanical reliability essential for critical structural applications.

Manufacturing Processes: Step-by-Step Comparison

Alloy casting involves melting the alloy and pouring it into molds to solidify, enabling complex shapes and internal cavities with minimal machining. Forging heats the alloy and deforms it under high pressure, resulting in superior grain structure, enhanced mechanical properties, and increased strength. Casting suits intricate designs and lower production volumes, while forging excels in durability and performance for critical components.

Cost Considerations: Alloy Casting vs. Forging

Alloy casting typically incurs lower initial tooling costs compared to forging, making it more economical for complex geometries and small production runs. Forging, although more expensive upfront due to die and equipment costs, offers superior material strength and reduced waste, which can lead to cost savings in high-volume manufacturing. The choice between casting and forging hinges on balancing upfront investment with long-term performance benefits and production scale.

Quality and Surface Finish Differences

Alloy casting provides intricate shapes with a uniform surface finish due to molten metal solidifying in molds, often resulting in minimal machining requirements and good dimensional accuracy. Forging enhances material quality through plastic deformation, increasing strength and grain flow continuity, which improves fatigue resistance but may require additional surface treatments for smooth finishes. Surface finish in casting varies by mold type and cooling rate, while forging typically achieves a superior mechanical property profile but with a rougher initial surface needing polishing for aesthetic or functional purposes.

Applications of Cast and Forged Alloys

Cast alloys find extensive application in complex-shaped components such as automotive engine blocks, pump housings, and aerospace turbine blades due to their ability to form intricate geometries with excellent wear resistance. Forged alloys are primarily used in high-stress applications like crankshafts, connecting rods, and aircraft landing gear, where superior strength, fatigue resistance, and structural integrity are paramount. The choice between casting and forging depends on performance requirements, with forged alloys favored in critical mechanical parts demanding high toughness and cast alloys utilized for detailed, cost-effective production.

Limitations and Challenges of Each Method

Alloy casting presents limitations such as porosity, shrinkage, and lower mechanical strength due to grain structure irregularities, which can lead to defects and reduced fatigue resistance. Forging challenges include higher production costs and complexity, limited geometric design flexibility, and significant energy consumption during the deformation process. Both methods require precise control over temperature and material properties to minimize defects and optimize performance.

Selecting the Right Process for Your Alloy Component

Selecting the right process for alloy components hinges on factors like mechanical strength, complexity, and cost efficiency. Alloy casting offers excellent design flexibility and is ideal for intricate shapes but often results in lower tensile strength compared to forging. Forging produces components with superior grain structure and enhanced durability, making it the preferred choice for high-stress applications requiring maximum reliability.

Alloy Casting vs Forging Infographic

materialdif.com

materialdif.com