Copper alloy offers superior electrical conductivity and corrosion resistance compared to bronze alloy, making it ideal for applications requiring efficient energy transfer. Bronze alloy, composed primarily of copper and tin, provides enhanced strength and wear resistance, suitable for heavy-duty mechanical components. Choosing between copper and bronze alloys depends on the specific needs for conductivity versus durability in industrial and decorative uses.

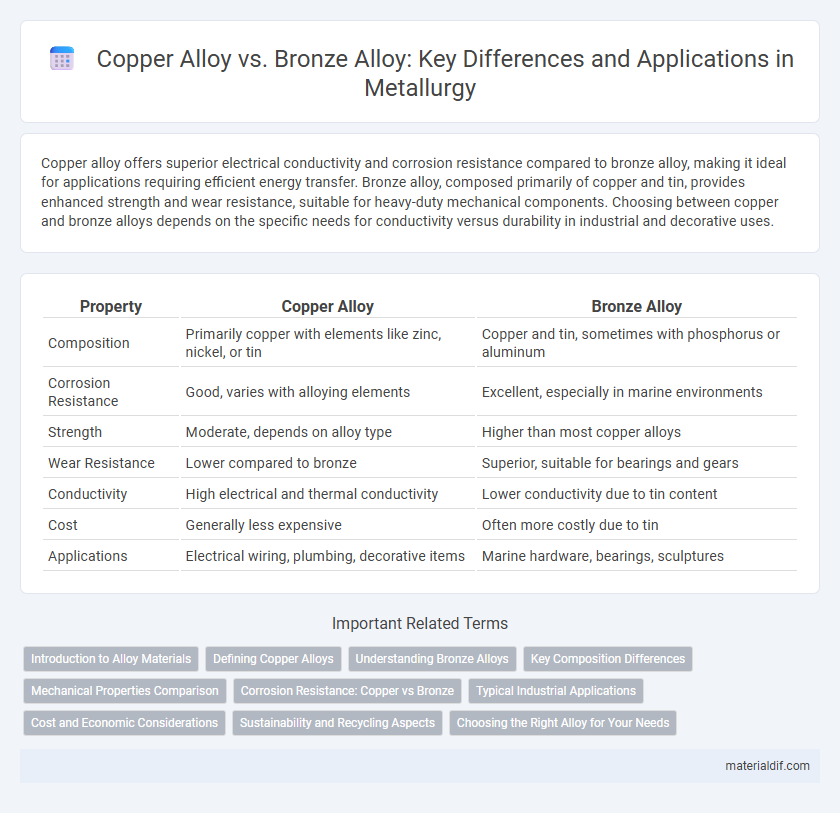

Table of Comparison

| Property | Copper Alloy | Bronze Alloy |

|---|---|---|

| Composition | Primarily copper with elements like zinc, nickel, or tin | Copper and tin, sometimes with phosphorus or aluminum |

| Corrosion Resistance | Good, varies with alloying elements | Excellent, especially in marine environments |

| Strength | Moderate, depends on alloy type | Higher than most copper alloys |

| Wear Resistance | Lower compared to bronze | Superior, suitable for bearings and gears |

| Conductivity | High electrical and thermal conductivity | Lower conductivity due to tin content |

| Cost | Generally less expensive | Often more costly due to tin |

| Applications | Electrical wiring, plumbing, decorative items | Marine hardware, bearings, sculptures |

Introduction to Alloy Materials

Copper alloy and bronze alloy are essential categories of metal materials known for their durability and corrosion resistance. Copper alloys primarily consist of copper combined with elements like zinc, nickel, or tin, enhancing strength and electrical conductivity. Bronze alloys specifically include copper and tin, offering superior hardness and wear resistance, making them ideal for applications in machinery, marine parts, and decorative items.

Defining Copper Alloys

Copper alloys are metallic mixtures primarily composed of copper combined with other elements such as zinc, tin, aluminum, or nickel to enhance properties like strength, corrosion resistance, and machinability. Bronze alloys specifically consist of copper and tin, sometimes with small amounts of phosphorus, manganese, or aluminum, making them distinct within the broader category of copper alloys. Defining copper alloys involves identifying the constituent elements and their proportions, which determine the alloy's mechanical characteristics and suitability for various industrial applications.

Understanding Bronze Alloys

Bronze alloys primarily consist of copper combined with tin, creating a material known for its hardness, corrosion resistance, and excellent wear properties compared to pure copper alloys. The addition of tin typically ranges from 5% to 20%, significantly enhancing mechanical strength and making bronze ideal for applications like bearings, gears, and sculptures. Understanding the specific composition and manufacturing processes of bronze alloys is crucial for optimizing their performance in industrial and artistic uses.

Key Composition Differences

Copper alloys primarily consist of copper combined with elements such as zinc, aluminum, and nickel, enhancing strength and corrosion resistance. Bronze alloys are a subset of copper alloys mainly composed of copper and tin, offering superior hardness and wear resistance. The tin content in bronze significantly influences its mechanical properties, distinguishing it from other copper-based alloys.

Mechanical Properties Comparison

Copper alloys generally exhibit higher electrical conductivity and better corrosion resistance, while bronze alloys, composed mainly of copper and tin, provide superior hardness and tensile strength. Bronze alloys demonstrate enhanced wear resistance and improved fatigue strength, making them ideal for applications requiring durability under mechanical stress. Mechanical properties such as yield strength and elongation are typically higher in bronze alloys, contributing to their widespread use in heavy-duty components.

Corrosion Resistance: Copper vs Bronze

Copper alloys generally exhibit excellent corrosion resistance in various environments, especially in marine and industrial atmospheres, due to their high copper content which forms a protective oxide layer. Bronze alloys, which are primarily copper combined with tin or other elements, often offer enhanced corrosion resistance compared to pure copper, particularly against stress corrosion cracking and dezincification when zinc is present. The specific corrosion resistance of copper versus bronze depends largely on the alloy composition and environmental conditions, with bronze providing superior durability in aggressive environments like saltwater and acidic conditions.

Typical Industrial Applications

Copper alloys are widely used in electrical connectors, heat exchangers, and plumbing components due to their excellent electrical conductivity and corrosion resistance. Bronze alloys, which primarily include copper and tin, find typical industrial applications in bearing bushings, marine hardware, and sculptures because of their superior wear resistance and low friction properties. Both alloys serve critical roles in manufacturing and construction, with copper alloys favored for conductivity and bronze alloys preferred for mechanical durability.

Cost and Economic Considerations

Copper alloys generally cost less than bronze alloys due to their simpler composition, primarily consisting of copper mixed with small amounts of other metals like zinc or nickel. Bronze alloys, which include significant tin content, often incur higher raw material costs and manufacturing expenses resulting from more complex production processes. Economic considerations favor copper alloys for budget-sensitive applications, while bronze alloys are preferred where corrosion resistance and durability justify the increased investment.

Sustainability and Recycling Aspects

Copper alloys generally offer higher sustainability due to their excellent recyclability and lower environmental impact during production compared to bronze alloys, which contain tin that requires more energy-intensive extraction. Recycling copper alloys reduces the need for virgin metal mining, significantly cutting carbon emissions and preserving natural resources. Bronze alloys, while recyclable, have a more complex composition that can complicate recycling processes and decrease overall material recovery efficiency.

Choosing the Right Alloy for Your Needs

Copper alloys offer superior electrical conductivity and corrosion resistance, making them ideal for wiring and plumbing applications, while bronze alloys provide enhanced strength and wear resistance, suitable for marine hardware and bearings. Selecting between copper and bronze alloys depends on the required mechanical properties, environmental exposure, and specific functional demands of the project. Evaluating factors such as tensile strength, machinability, and cost efficiency will guide the optimal choice of alloy for durability and performance.

Copper alloy vs Bronze alloy Infographic

materialdif.com

materialdif.com