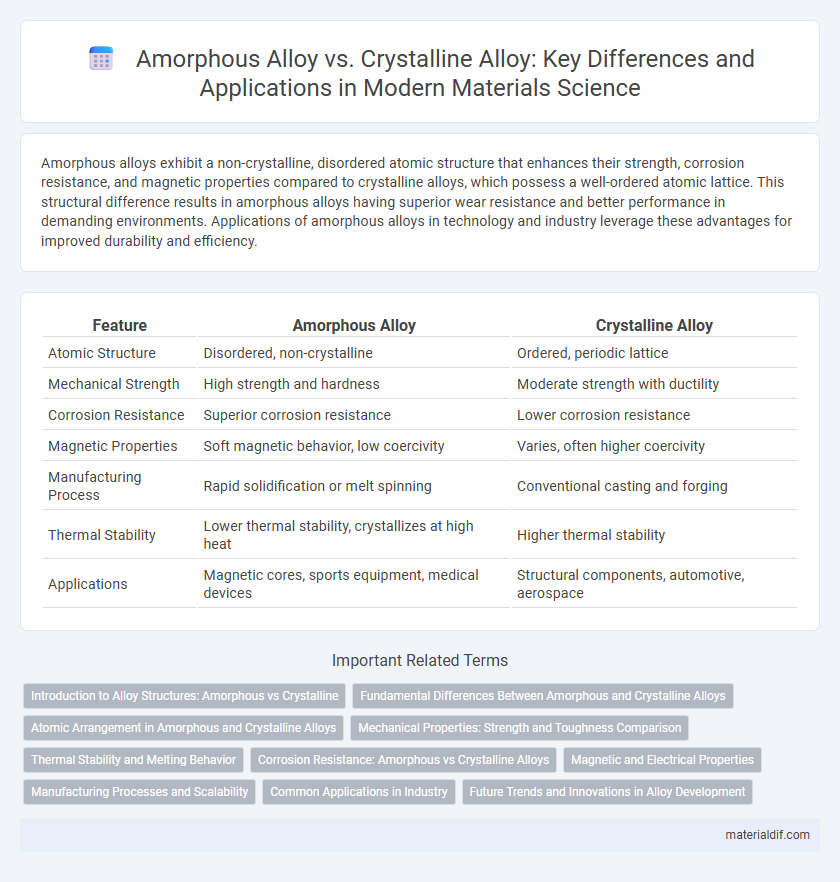

Amorphous alloys exhibit a non-crystalline, disordered atomic structure that enhances their strength, corrosion resistance, and magnetic properties compared to crystalline alloys, which possess a well-ordered atomic lattice. This structural difference results in amorphous alloys having superior wear resistance and better performance in demanding environments. Applications of amorphous alloys in technology and industry leverage these advantages for improved durability and efficiency.

Table of Comparison

| Feature | Amorphous Alloy | Crystalline Alloy |

|---|---|---|

| Atomic Structure | Disordered, non-crystalline | Ordered, periodic lattice |

| Mechanical Strength | High strength and hardness | Moderate strength with ductility |

| Corrosion Resistance | Superior corrosion resistance | Lower corrosion resistance |

| Magnetic Properties | Soft magnetic behavior, low coercivity | Varies, often higher coercivity |

| Manufacturing Process | Rapid solidification or melt spinning | Conventional casting and forging |

| Thermal Stability | Lower thermal stability, crystallizes at high heat | Higher thermal stability |

| Applications | Magnetic cores, sports equipment, medical devices | Structural components, automotive, aerospace |

Introduction to Alloy Structures: Amorphous vs Crystalline

Amorphous alloys lack the long-range ordered atomic structure found in crystalline alloys, resulting in a disordered atomic arrangement that imparts unique mechanical and magnetic properties. Crystalline alloys exhibit a repeating, well-defined lattice structure, which provides distinct grain boundaries contributing to their strength and ductility. Understanding the structural differences between amorphous and crystalline alloys is essential for optimizing material performance in applications such as aerospace, electronics, and magnetic devices.

Fundamental Differences Between Amorphous and Crystalline Alloys

Amorphous alloys, also known as metallic glasses, lack a long-range ordered atomic structure, distinguishing them fundamentally from crystalline alloys, which possess a well-defined, periodic lattice arrangement. This structural difference results in amorphous alloys exhibiting unique properties such as high strength, corrosion resistance, and magnetic softness due to the absence of grain boundaries present in crystalline counterparts. The atomic disorder in amorphous alloys leads to isotropic mechanical behavior, whereas crystalline alloys demonstrate anisotropic properties influenced by grain orientation and defects.

Atomic Arrangement in Amorphous and Crystalline Alloys

Amorphous alloys feature a disordered atomic arrangement lacking long-range periodicity, which differentiates them from crystalline alloys that exhibit a well-defined, repeating lattice structure. This irregular atomic distribution in amorphous alloys results in unique mechanical and magnetic properties, such as enhanced strength and corrosion resistance. In contrast, the orderly atomic arrangement in crystalline alloys contributes to their predictable phase behavior and anisotropic physical characteristics.

Mechanical Properties: Strength and Toughness Comparison

Amorphous alloys exhibit higher strength and improved toughness compared to crystalline alloys due to their non-ordered atomic structure, which hinders dislocation motion and enhances resistance to deformation. The lack of grain boundaries in amorphous alloys contributes to uniform stress distribution and increased fracture toughness. In contrast, crystalline alloys often show lower strength but can have higher ductility because of slip systems activated by their regular lattice arrangement.

Thermal Stability and Melting Behavior

Amorphous alloys exhibit superior thermal stability due to their non-crystalline atomic structure, which resists grain boundary diffusion and delays crystallization during heating. Crystalline alloys, characterized by ordered atomic arrangements, typically undergo distinct melting points and phase transitions, causing less uniform melting behavior. The lack of grain boundaries in amorphous alloys contributes to a broader melting range and enhanced resistance to thermal deformation compared to the defined melting and solidification processes in crystalline alloys.

Corrosion Resistance: Amorphous vs Crystalline Alloys

Amorphous alloys exhibit superior corrosion resistance compared to crystalline alloys due to their non-crystalline atomic structure, which eliminates grain boundaries and reduces sites for corrosion initiation. This homogeneous atomic arrangement enhances chemical stability and minimizes localized corrosion often observed in crystalline alloys. Consequently, amorphous alloys are preferred in harsh chemical environments where durability and resistance to oxidative degradation are critical.

Magnetic and Electrical Properties

Amorphous alloys exhibit unique magnetic properties such as low coercivity and high magnetic permeability, making them ideal for transformer cores and magnetic sensors, while their lack of grain boundaries results in reduced electrical resistivity. In contrast, crystalline alloys have defined grain structures that increase magnetic anisotropy and electrical resistance, often limiting their performance in high-frequency applications. The absence of long-range atomic order in amorphous alloys also contributes to minimized eddy current losses and enhanced soft magnetic behavior compared to their crystalline counterparts.

Manufacturing Processes and Scalability

Amorphous alloys are produced through rapid cooling techniques such as melt spinning or atomization, which limit the material's scalability due to the need for precise cooling rates to maintain their non-crystalline structure. Crystalline alloys are typically manufactured using casting, forging, or additive manufacturing methods that allow for easier scalability and mass production in industrial settings. The complexity of controlling cooling rates in amorphous alloys presents challenges in large-scale manufacturing compared to the well-established processes used for crystalline alloys.

Common Applications in Industry

Amorphous alloys, known as metallic glasses, are extensively used in transformer cores and magnetic sensors due to their superior soft magnetic properties and high electrical resistivity. Crystalline alloys are prevalent in aerospace, automotive, and construction industries, where their well-defined grain structure provides enhanced mechanical strength and corrosion resistance. Both alloys find critical roles in electronic components, with amorphous alloys favored for precision magnetic applications and crystalline alloys for structural components.

Future Trends and Innovations in Alloy Development

Future trends in alloy development are steering toward enhancing the unique properties of amorphous alloys, such as superior strength and corrosion resistance, through advanced manufacturing techniques like additive manufacturing and rapid solidification. Innovations in crystalline alloys focus on optimizing grain size and phase composition using machine learning algorithms to achieve unprecedented mechanical performance and thermal stability. Research into hybrid alloys combining amorphous and crystalline phases aims to create materials with tailored magnetic and mechanical properties for cutting-edge applications in aerospace and electronics.

Amorphous alloy vs Crystalline alloy Infographic

materialdif.com

materialdif.com