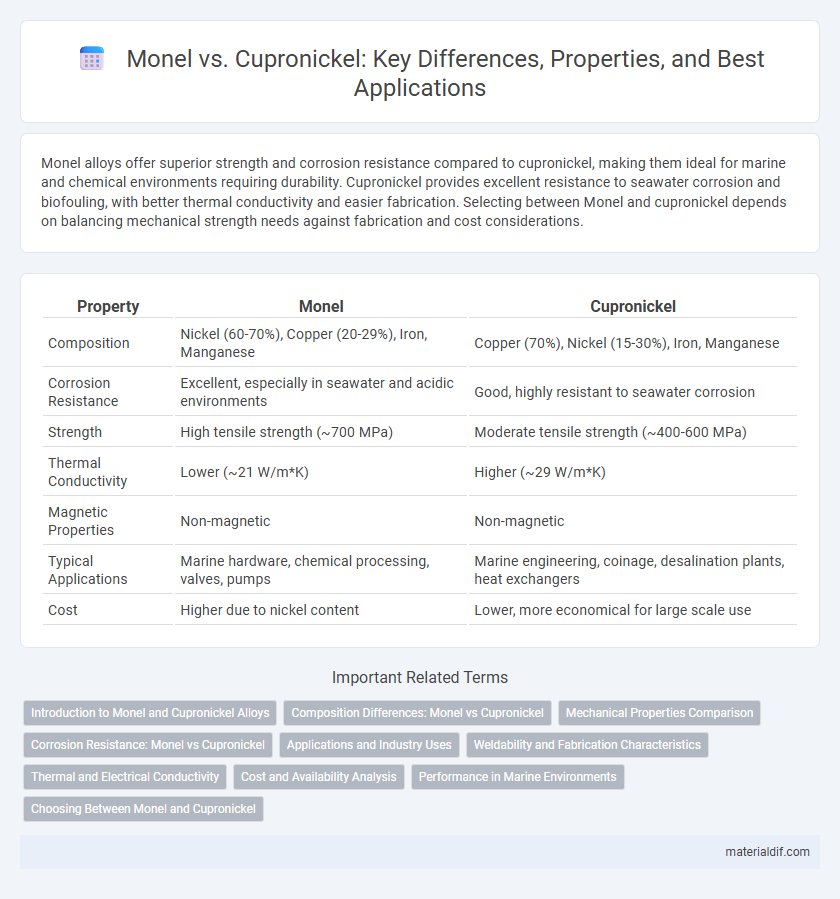

Monel alloys offer superior strength and corrosion resistance compared to cupronickel, making them ideal for marine and chemical environments requiring durability. Cupronickel provides excellent resistance to seawater corrosion and biofouling, with better thermal conductivity and easier fabrication. Selecting between Monel and cupronickel depends on balancing mechanical strength needs against fabrication and cost considerations.

Table of Comparison

| Property | Monel | Cupronickel |

|---|---|---|

| Composition | Nickel (60-70%), Copper (20-29%), Iron, Manganese | Copper (70%), Nickel (15-30%), Iron, Manganese |

| Corrosion Resistance | Excellent, especially in seawater and acidic environments | Good, highly resistant to seawater corrosion |

| Strength | High tensile strength (~700 MPa) | Moderate tensile strength (~400-600 MPa) |

| Thermal Conductivity | Lower (~21 W/m*K) | Higher (~29 W/m*K) |

| Magnetic Properties | Non-magnetic | Non-magnetic |

| Typical Applications | Marine hardware, chemical processing, valves, pumps | Marine engineering, coinage, desalination plants, heat exchangers |

| Cost | Higher due to nickel content | Lower, more economical for large scale use |

Introduction to Monel and Cupronickel Alloys

Monel alloys, primarily composed of nickel (up to 67%) and copper, are renowned for their exceptional corrosion resistance and strength, making them ideal for marine and chemical environments. Cupronickel alloys feature a higher copper content (typically 70%) combined with nickel and iron, offering excellent resistance to seawater corrosion and biofouling. Both Monel and Cupronickel alloys are widely used in applications requiring durability and resistance to harsh conditions, but Monel generally exhibits superior mechanical properties and higher nickel content.

Composition Differences: Monel vs Cupronickel

Monel primarily consists of approximately 67% nickel and 28-30% copper, with small amounts of iron, manganese, carbon, and silicon, offering superior strength and corrosion resistance. Cupronickel typically contains 70% copper with 10-30% nickel, enhancing its resistance to seawater corrosion and reducing biofouling. The higher nickel content in Monel results in greater mechanical strength, while Cupronickel's composition is optimized for marine applications requiring excellent thermal conductivity and corrosion resistance.

Mechanical Properties Comparison

Monel alloys exhibit higher tensile strength and superior corrosion resistance compared to Cupronickel, making them ideal for demanding marine and chemical environments. Cupronickel offers better ductility and thermal conductivity, which enhances its performance in heat exchange and seawater piping applications. Both alloys maintain excellent fatigue strength, but Monel generally withstands higher stress and wear conditions.

Corrosion Resistance: Monel vs Cupronickel

Monel exhibits superior corrosion resistance compared to cupronickel, especially in highly acidic and alkaline environments where its nickel content enhances durability. Cupronickel performs exceptionally well against seawater corrosion due to its high copper composition, making it ideal for marine applications. Both alloys resist corrosion effectively, but Monel's resilience in harsh chemical environments gives it an edge over cupronickel.

Applications and Industry Uses

Monel alloys, known for exceptional corrosion resistance and strength, are extensively used in marine engineering, chemical processing, and aerospace industries. Cupronickel, with superior resistance to seawater corrosion and biofouling, finds widespread application in desalination plants, marine hardware, and coinage. The robust mechanical properties of Monel make it ideal for high-stress environments, while Cupronickel's antimicrobial features benefit medical equipment and shipbuilding.

Weldability and Fabrication Characteristics

Monel exhibits superior weldability compared to Cupronickel due to its higher nickel content and homogeneous microstructure, which reduces cracking risk during high-temperature fabrication processes. Cupronickel alloys, while corrosion-resistant and ductile, require more precise control of welding parameters to avoid grain growth and maintain mechanical properties. Fabrication of Monel is generally easier, allowing for smoother machining and forming operations, whereas Cupronickel may need specialized techniques to preserve its structural integrity.

Thermal and Electrical Conductivity

Monel alloys exhibit lower thermal and electrical conductivity compared to Cupronickel, with Monel typically around 22 W/m*K for thermal conductivity and 14% IACS for electrical conductivity. Cupronickel alloys offer higher thermal conductivity, generally ranging from 29 to 37 W/m*K, and electrical conductivity between 20% and 45% IACS, making them more efficient in heat dissipation and electrical applications. The difference in conductivity is primarily due to the higher nickel content and microstructural variations in Monel, which reduce electron mobility relative to Cupronickel.

Cost and Availability Analysis

Monel alloy, composed primarily of nickel and copper, generally commands a higher price due to its superior corrosion resistance and strength, but its availability is more limited compared to cupronickel, which is a more common and cost-effective copper-nickel alloy variant favored for marine applications. Cupronickel typically offers greater accessibility and lower costs, making it suitable for large-scale projects requiring good corrosion resistance in seawater environments. The cost difference is influenced by nickel content and market demand, with Monel's higher nickel percentage driving prices up and impacting supply chain stability.

Performance in Marine Environments

Monel alloys exhibit superior corrosion resistance and strength in marine environments compared to Cupronickel, making them ideal for aggressive saltwater applications such as seawater piping and marine hardware. Cupronickel, while also resistant to seawater corrosion, offers better resistance to biofouling and is typically more cost-effective for less demanding marine components like heat exchangers and condenser tubes. Both alloys perform well in saltwater but Monel excels under extreme conditions due to its higher nickel and copper content, resulting in enhanced durability and longevity.

Choosing Between Monel and Cupronickel

Choosing between Monel and Cupronickel depends on the specific application requirements, such as corrosion resistance and mechanical strength. Monel alloys, composed primarily of nickel and copper, exhibit superior resistance to seawater and acidic environments, making them ideal for marine and chemical processing industries. Cupronickel, with a higher copper content and added iron and manganese, offers excellent thermal conductivity and is preferred for heat exchangers and coinage due to its balance of strength and corrosion resistance.

Monel vs Cupronickel Infographic

materialdif.com

materialdif.com