Age hardening increases alloy strength by precipitating fine particles within the metal matrix through controlled heat treatment, enhancing hardness and mechanical properties over time. Work hardening, on the other hand, strengthens the alloy by plastic deformation, which creates dislocations that hinder further movement and increase resistance to deformation. Age hardening offers superior long-term stability and strength retention compared to the temporary and strain-induced effects of work hardening.

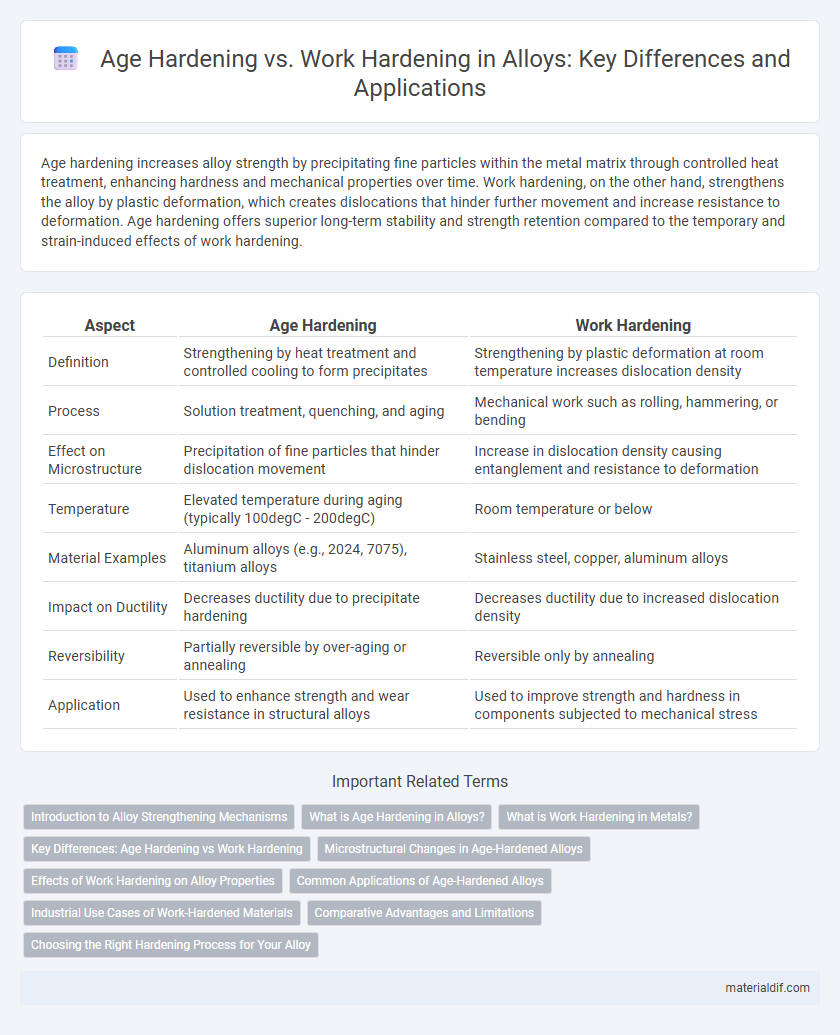

Table of Comparison

| Aspect | Age Hardening | Work Hardening |

|---|---|---|

| Definition | Strengthening by heat treatment and controlled cooling to form precipitates | Strengthening by plastic deformation at room temperature increases dislocation density |

| Process | Solution treatment, quenching, and aging | Mechanical work such as rolling, hammering, or bending |

| Effect on Microstructure | Precipitation of fine particles that hinder dislocation movement | Increase in dislocation density causing entanglement and resistance to deformation |

| Temperature | Elevated temperature during aging (typically 100degC - 200degC) | Room temperature or below |

| Material Examples | Aluminum alloys (e.g., 2024, 7075), titanium alloys | Stainless steel, copper, aluminum alloys |

| Impact on Ductility | Decreases ductility due to precipitate hardening | Decreases ductility due to increased dislocation density |

| Reversibility | Partially reversible by over-aging or annealing | Reversible only by annealing |

| Application | Used to enhance strength and wear resistance in structural alloys | Used to improve strength and hardness in components subjected to mechanical stress |

Introduction to Alloy Strengthening Mechanisms

Age hardening increases alloy strength through controlled precipitation of finely dispersed particles within the metal matrix, hindering dislocation motion and enhancing mechanical properties. Work hardening, or strain hardening, strengthens alloys by introducing dislocations and defects during plastic deformation, which increases resistance to further deformation. Both mechanisms improve alloy durability but operate through distinct microstructural changes affecting dislocation interactions.

What is Age Hardening in Alloys?

Age hardening in alloys, also known as precipitation hardening, is a heat treatment process that increases strength and hardness by forming fine precipitates within the metal matrix. This method involves solution treating the alloy at high temperatures, quenching to retain a supersaturated solid solution, and then aging at elevated temperatures to allow precipitate formation. Age hardening is commonly used in aluminum, titanium, and nickel alloys to enhance mechanical properties without significant deformation.

What is Work Hardening in Metals?

Work hardening in metals, also known as strain hardening, is the process where a metal becomes stronger and harder through plastic deformation at temperatures below its recrystallization point. This occurs as dislocations in the metal's crystal structure multiply and interact, impeding further movement and increasing yield strength. Unlike age hardening, which relies on phase changes and precipitation, work hardening enhances mechanical properties solely through mechanical strain.

Key Differences: Age Hardening vs Work Hardening

Age hardening, also known as precipitation hardening, involves the formation of fine particles within the metal matrix over time at elevated temperatures, significantly increasing alloy strength and hardness. Work hardening, or strain hardening, results from plastic deformation at room temperature, causing dislocation movements that enhance metal hardness and tensile strength without altering its microstructure. Key differences include the mechanisms: thermal treatment versus mechanical deformation, and the changes in microstructure versus dislocation density, essential in optimizing alloy performance for aerospace and automotive applications.

Microstructural Changes in Age-Hardened Alloys

Age hardening in alloys involves the formation and growth of fine, coherent precipitates within the microstructure, which obstruct dislocation motion and enhance strength through precipitation strengthening. These precipitates typically nucleate during the aging process from a supersaturated solid solution, resulting in distinct phase transformations that refine the grain boundary structure and increase hardness. Work hardening, by contrast, primarily increases dislocation density without altering the phase composition, leading to strain-induced strengthening rather than microstructural evolution as seen in age-hardened alloys.

Effects of Work Hardening on Alloy Properties

Work hardening increases the dislocation density within an alloy's crystal structure, leading to enhanced strength and hardness while reducing ductility and toughness. This process refines the microstructure, improving wear resistance but potentially causing brittleness under high stress conditions. The balance between strength and flexibility is critical for applications requiring durable yet formable alloy components.

Common Applications of Age-Hardened Alloys

Age-hardened alloys are widely used in aerospace components, automotive parts, and high-performance sporting goods due to their enhanced mechanical strength and improved fatigue resistance. These alloys undergo heat treatment processes that promote precipitation hardening, crucial for achieving optimal hardness and durability. Common examples include aluminum-copper, aluminum-magnesium-silicon, and titanium-based alloys utilized for structural and load-bearing applications.

Industrial Use Cases of Work-Hardened Materials

Work hardening, also known as strain hardening, enhances metal strength and durability through plastic deformation, making it ideal for industrial applications where increased wear resistance and fatigue strength are essential, such as in automotive components and aerospace fasteners. Unlike age hardening, which relies on heat treatment to precipitate strengthening phases in alloys like aluminum or titanium, work hardening improves mechanical properties instantly during manufacturing processes like rolling, forging, and cold drawing. Industrial sectors benefit from work-hardened materials in tooling, structural frameworks, and heavy machinery parts where immediate strength gain and surface hardening are critical for performance and longevity.

Comparative Advantages and Limitations

Age hardening enhances alloy strength by precipitating fine particles that impede dislocation movement, offering superior hardness and thermal stability compared to work hardening. Work hardening improves strength through dislocation density increase during plastic deformation but can lead to reduced ductility and limited thermal resistance. Age hardening is advantageous for applications requiring high strength at elevated temperatures, while work hardening suits components subjected to mechanical strain without significant heat exposure.

Choosing the Right Hardening Process for Your Alloy

Age hardening enhances alloy strength through controlled heat treatment that precipitates fine particles within the metal matrix, making it ideal for aluminum and titanium alloys requiring high performance. Work hardening increases strength by plastic deformation, commonly used in alloys like copper and stainless steel where mechanical processing is feasible. Selecting the appropriate hardening process depends on the alloy composition, desired mechanical properties, and application requirements, with age hardening providing precise strength control and work hardening offering improved ductility and toughness.

Age Hardening vs Work Hardening Infographic

materialdif.com

materialdif.com