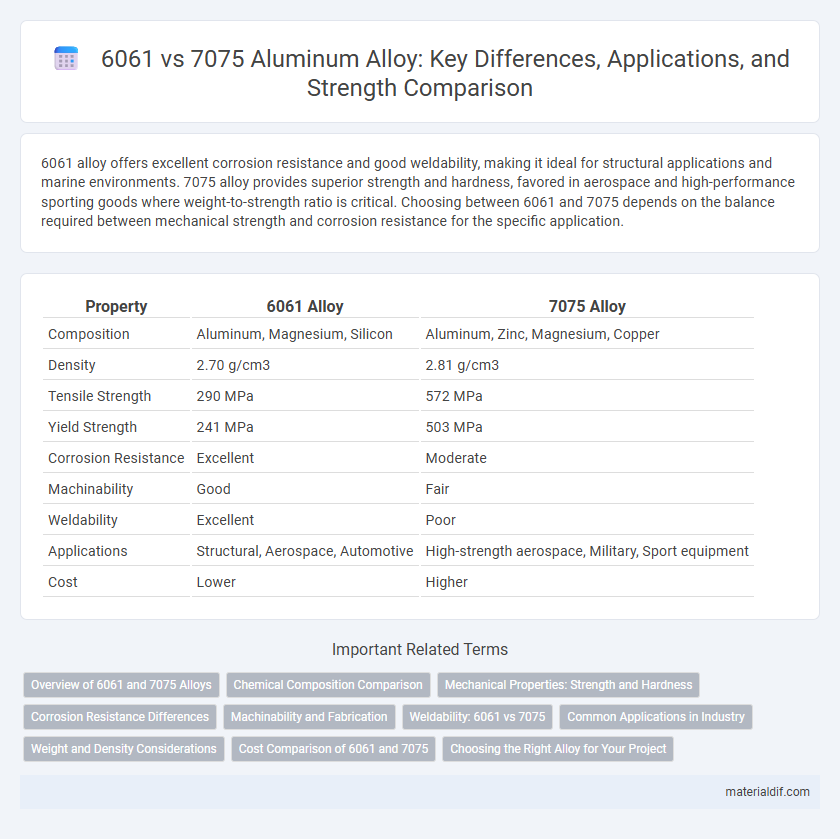

6061 alloy offers excellent corrosion resistance and good weldability, making it ideal for structural applications and marine environments. 7075 alloy provides superior strength and hardness, favored in aerospace and high-performance sporting goods where weight-to-strength ratio is critical. Choosing between 6061 and 7075 depends on the balance required between mechanical strength and corrosion resistance for the specific application.

Table of Comparison

| Property | 6061 Alloy | 7075 Alloy |

|---|---|---|

| Composition | Aluminum, Magnesium, Silicon | Aluminum, Zinc, Magnesium, Copper |

| Density | 2.70 g/cm3 | 2.81 g/cm3 |

| Tensile Strength | 290 MPa | 572 MPa |

| Yield Strength | 241 MPa | 503 MPa |

| Corrosion Resistance | Excellent | Moderate |

| Machinability | Good | Fair |

| Weldability | Excellent | Poor |

| Applications | Structural, Aerospace, Automotive | High-strength aerospace, Military, Sport equipment |

| Cost | Lower | Higher |

Overview of 6061 and 7075 Alloys

6061 alloy is a versatile aluminum alloy known for its excellent corrosion resistance, good mechanical properties, and weldability, making it ideal for structural applications. 7075 alloy offers higher strength and superior fatigue resistance due to its zinc-based composition, commonly used in aerospace and high-performance engineering. Both alloys provide distinct advantages depending on the balance desired between strength, machinability, and corrosion resistance.

Chemical Composition Comparison

6061 aluminum alloy contains primarily magnesium (around 0.8-1.2%) and silicon (0.4-0.8%), offering good strength and corrosion resistance. In contrast, 7075 alloy is enriched with zinc (5.1-6.1%), along with magnesium (2.1-2.9%) and copper (1.2-2.0%), resulting in superior strength but lower corrosion resistance. The significant difference in zinc and copper content between 6061 and 7075 alloys directly influences their mechanical properties and applications.

Mechanical Properties: Strength and Hardness

Alloy 7075 exhibits higher tensile strength, reaching up to 83,000 psi, compared to Alloy 6061's maximum of approximately 45,000 psi, making it ideal for high-stress applications. The hardness of 7075, typically around 150 HB, surpasses 6061's average of 95 HB, providing superior resistance to wear and deformation. These mechanical properties position 7075 as a preferred choice for aerospace and military components where strength and durability are critical.

Corrosion Resistance Differences

6061 aluminum alloy exhibits superior corrosion resistance compared to 7075, particularly in marine and industrial environments. The higher zinc content in 7075 makes it more vulnerable to stress corrosion cracking and pitting corrosion, reducing its durability in harsh conditions. Protective coatings are often necessary for 7075 to enhance its corrosion resistance, whereas 6061 commonly performs well with minimal treatment.

Machinability and Fabrication

6061 aluminum offers superior machinability due to its balanced composition of magnesium and silicon, making it ideal for complex fabrication processes and easier cutting with standard tools. In contrast, 7075 aluminum, with its high zinc content, provides greater strength but is tougher to machine, requiring specialized equipment and techniques to avoid tool wear and maintain precision. Fabrication of 6061 is more straightforward, accommodating welding and bending better than 7075, which is less ductile and more prone to cracking during forming.

Weldability: 6061 vs 7075

6061 aluminum alloy offers superior weldability due to its excellent corrosion resistance and ability to retain strength after welding, making it ideal for structural applications requiring fabrication. In contrast, 7075 aluminum has poor weldability because it is prone to cracking and strength loss in the heat-affected zone, limiting its use in welded structures. Choosing 6061 over 7075 ensures better weld quality and durability in projects involving extensive joining processes.

Common Applications in Industry

6061 aluminum is widely used in structural applications such as aerospace frames, automotive parts, and marine components due to its excellent corrosion resistance and weldability. 7075 aluminum is favored in high-stress environments like aircraft fittings, missile components, and competitive sporting goods because of its superior strength-to-weight ratio. Both alloys are integral in manufacturing parts where specific mechanical properties like strength, durability, and corrosion resistance determine material selection.

Weight and Density Considerations

Alloy 6061 has a density of approximately 2.70 g/cm3, making it slightly lighter compared to Alloy 7075, which has a density around 2.81 g/cm3. The lower density of 6061 makes it more suitable for applications where weight reduction is critical but extreme strength is not the primary concern. Conversely, 7075 offers higher strength-to-weight ratio despite its higher density, favored in aerospace and high-performance engineering.

Cost Comparison of 6061 and 7075

6061 aluminum alloy is generally more cost-effective than 7075 due to its wider availability and simpler processing requirements. While 7075 offers higher strength and is preferred for aerospace applications, its higher alloying content and complex heat treatment contribute to increased production costs. For projects prioritizing budget without extreme strength demands, 6061 provides a balanced choice with favorable machinability and corrosion resistance at a lower price point.

Choosing the Right Alloy for Your Project

6061 aluminum offers excellent corrosion resistance and good weldability, making it ideal for structural applications requiring moderate strength and versatility. 7075 aluminum provides higher tensile strength and superior fatigue resistance, suited for aerospace and high-performance engineering where maximum strength-to-weight ratio is critical. Selecting between 6061 and 7075 hinges on balancing strength requirements, corrosion resistance, and machinability to fit the specific demands of your project.

6061 vs 7075 Infographic

materialdif.com

materialdif.com