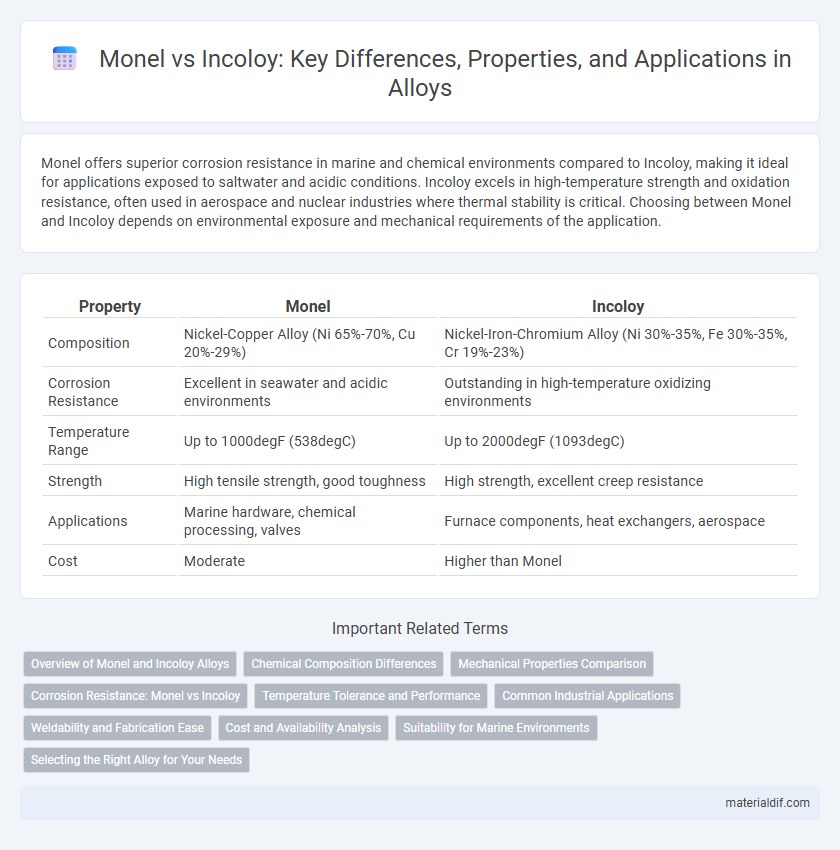

Monel offers superior corrosion resistance in marine and chemical environments compared to Incoloy, making it ideal for applications exposed to saltwater and acidic conditions. Incoloy excels in high-temperature strength and oxidation resistance, often used in aerospace and nuclear industries where thermal stability is critical. Choosing between Monel and Incoloy depends on environmental exposure and mechanical requirements of the application.

Table of Comparison

| Property | Monel | Incoloy |

|---|---|---|

| Composition | Nickel-Copper Alloy (Ni 65%-70%, Cu 20%-29%) | Nickel-Iron-Chromium Alloy (Ni 30%-35%, Fe 30%-35%, Cr 19%-23%) |

| Corrosion Resistance | Excellent in seawater and acidic environments | Outstanding in high-temperature oxidizing environments |

| Temperature Range | Up to 1000degF (538degC) | Up to 2000degF (1093degC) |

| Strength | High tensile strength, good toughness | High strength, excellent creep resistance |

| Applications | Marine hardware, chemical processing, valves | Furnace components, heat exchangers, aerospace |

| Cost | Moderate | Higher than Monel |

Overview of Monel and Incoloy Alloys

Monel alloys primarily consist of nickel and copper, known for their exceptional corrosion resistance in marine and chemical environments, making them ideal for applications involving seawater and acidic conditions. Incoloy alloys, composed mainly of nickel, iron, and chromium, offer superior oxidation and heat resistance, suited for high-temperature industrial processes such as gas turbines and heat exchangers. Both Monel and Incoloy exhibit excellent mechanical properties, but Monel excels in corrosion resistance while Incoloy is preferred for thermal stability under extreme heat.

Chemical Composition Differences

Monel primarily consists of approximately 65-70% nickel and 20-29% copper, with small amounts of iron, manganese, and other trace elements, offering excellent corrosion resistance in marine environments. Incoloy is predominantly a nickel-iron alloy containing about 30-35% nickel, 13-21% chromium, and smaller percentages of molybdenum, iron, and copper, designed for high strength and oxidation resistance at elevated temperatures. The key chemical difference lies in Monel's high copper content enhancing corrosion resistance, while Incoloy's chromium and molybdenum content contribute to superior heat and oxidation resistance.

Mechanical Properties Comparison

Monel alloys exhibit superior tensile strength and excellent resistance to corrosion, making them ideal for high-stress marine and chemical environments. Incoloy, composed primarily of nickel, iron, and chromium, offers exceptional high-temperature strength and oxidation resistance, suitable for aerospace and power generation applications. Mechanical properties such as yield strength and elongation percentage vary, with Monel providing greater ductility while Incoloy maintains structural integrity under extreme thermal conditions.

Corrosion Resistance: Monel vs Incoloy

Monel alloys exhibit exceptional corrosion resistance, particularly against seawater, acids, and alkalis, making them ideal for marine and chemical processing environments. Incoloy alloys, composed primarily of nickel, iron, and chromium, offer superior resistance to high-temperature oxidation and carburization, suited for oil refining and gas processing applications. The choice between Monel and Incoloy depends on specific corrosion challenges; Monel excels in chloride-containing environments, while Incoloy withstands oxidizing and sulfidizing atmospheres at elevated temperatures.

Temperature Tolerance and Performance

Monel alloys exhibit excellent temperature tolerance up to approximately 1,000degF (540degC), making them ideal for high-performance applications involving marine and chemical environments. Incoloy alloys tolerate significantly higher temperatures, often exceeding 2,000degF (1,093degC), which enhances their performance in extreme heat conditions such as furnace components and heat exchangers. The superior thermal stability of Incoloy provides enhanced oxidation resistance and mechanical strength at elevated temperatures compared to Monel.

Common Industrial Applications

Monel alloys, composed primarily of nickel and copper, are widely used in marine engineering, chemical processing, and aerospace applications due to their excellent corrosion resistance and strength in seawater and acidic environments. Incoloy, a nickel-iron-chromium alloy, is favored in high-temperature industrial settings such as heat exchangers, gas turbines, and nuclear reactors for its exceptional oxidation and carburization resistance. Both alloys demonstrate critical roles in industries demanding durability under extreme chemical and thermal conditions.

Weldability and Fabrication Ease

Monel exhibits excellent weldability due to its high nickel and copper content, allowing strong, corrosion-resistant welds without cracking or brittleness, making it ideal for marine and chemical applications. Incoloy, while also weldable, requires more precise control during fabrication because of its iron-nickel-chromium composition, which can lead to sensitization or carbide precipitation if improperly cooled. Both alloys necessitate specialized welding techniques, but Monel generally offers easier fabrication and better resistance to post-weld corrosion.

Cost and Availability Analysis

Monel alloys generally offer lower cost options compared to Incoloy, making them a budget-friendly choice for corrosion-resistant applications. Availability of Monel is widespread due to its established use in marine and chemical environments, ensuring faster procurement and lower lead times. Incoloy, while more expensive, provides superior high-temperature strength and is less common, which can result in longer delivery times and higher overall project costs.

Suitability for Marine Environments

Monel alloys, primarily composed of nickel and copper, offer exceptional resistance to seawater corrosion, making them highly suitable for marine environments such as ship hulls, seawater piping, and marine fasteners. Incoloy, an iron-nickel-chromium alloy, provides moderate corrosion resistance with enhanced strength at high temperatures but is less resistant to chloride-induced stress corrosion cracking compared to Monel. For applications exposed to aggressive saltwater conditions, Monel is preferable due to its superior pitting and crevice corrosion resistance.

Selecting the Right Alloy for Your Needs

Monel offers superior corrosion resistance in marine and chemical environments, making it ideal for applications requiring strength and resistance to saltwater and acids. Incoloy excels in high-temperature oxidation and carburization resistance, suited for furnace components, heat exchangers, and gas turbines exposed to extreme heat. Choosing between Monel and Incoloy depends on whether corrosion resistance or high-temperature durability is the primary requirement for your specific industrial application.

Monel vs Incoloy Infographic

materialdif.com

materialdif.com