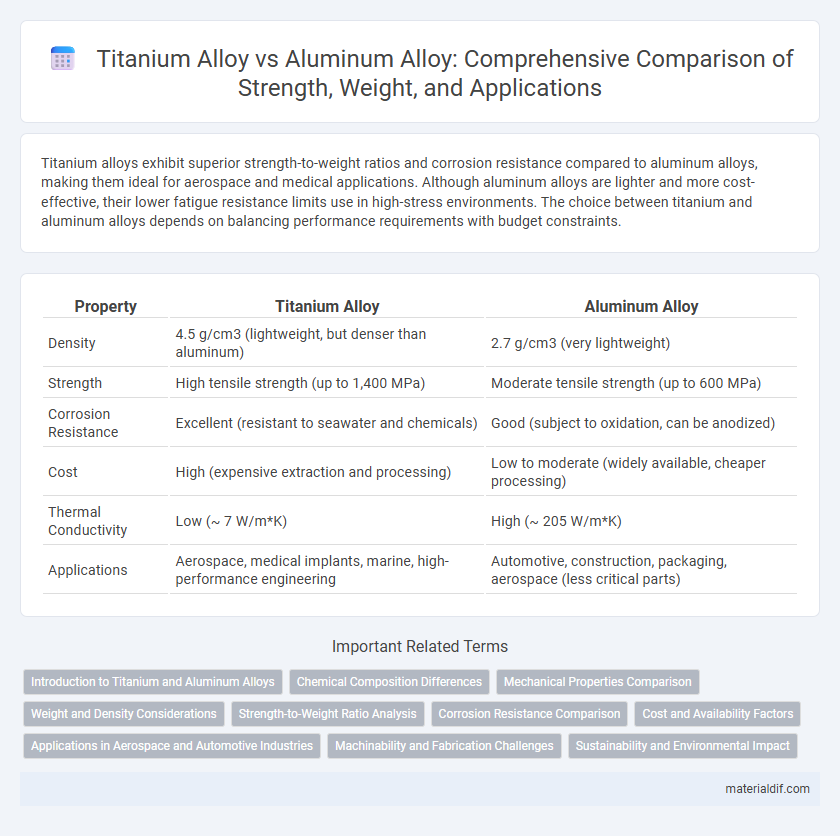

Titanium alloys exhibit superior strength-to-weight ratios and corrosion resistance compared to aluminum alloys, making them ideal for aerospace and medical applications. Although aluminum alloys are lighter and more cost-effective, their lower fatigue resistance limits use in high-stress environments. The choice between titanium and aluminum alloys depends on balancing performance requirements with budget constraints.

Table of Comparison

| Property | Titanium Alloy | Aluminum Alloy |

|---|---|---|

| Density | 4.5 g/cm3 (lightweight, but denser than aluminum) | 2.7 g/cm3 (very lightweight) |

| Strength | High tensile strength (up to 1,400 MPa) | Moderate tensile strength (up to 600 MPa) |

| Corrosion Resistance | Excellent (resistant to seawater and chemicals) | Good (subject to oxidation, can be anodized) |

| Cost | High (expensive extraction and processing) | Low to moderate (widely available, cheaper processing) |

| Thermal Conductivity | Low (~ 7 W/m*K) | High (~ 205 W/m*K) |

| Applications | Aerospace, medical implants, marine, high-performance engineering | Automotive, construction, packaging, aerospace (less critical parts) |

Introduction to Titanium and Aluminum Alloys

Titanium alloys exhibit exceptional strength-to-weight ratios and corrosion resistance, making them ideal for aerospace and medical applications. Aluminum alloys provide excellent machinability and thermal conductivity while maintaining a lightweight profile for automotive and structural uses. Both titanium and aluminum alloys offer unique mechanical properties tailored to specific engineering demands.

Chemical Composition Differences

Titanium alloys primarily consist of titanium combined with aluminum, vanadium, and trace elements, providing high strength and corrosion resistance. Aluminum alloys mainly comprise aluminum with elements such as copper, magnesium, silicon, and zinc, offering lightweight and good conductivity. The chemical composition difference results in titanium alloys having superior mechanical properties and corrosion resistance, whereas aluminum alloys are favored for their lighter weight and cost-effectiveness.

Mechanical Properties Comparison

Titanium alloys exhibit superior mechanical properties compared to aluminum alloys, featuring higher tensile strength typically ranging from 900 to 1400 MPa versus aluminum's 200 to 600 MPa. Titanium alloys also demonstrate a higher modulus of elasticity around 110 GPa, enhancing stiffness and resistance to deformation under load, while aluminum alloys have a modulus near 69 GPa. Fatigue resistance and corrosion resistance of titanium alloys outperform aluminum alloys, making titanium more suitable for high-performance and aerospace applications where strength-to-weight ratio is critical.

Weight and Density Considerations

Titanium alloys offer a superior strength-to-weight ratio compared to aluminum alloys, making them ideal for applications where minimizing weight is critical. Titanium alloy density typically ranges around 4.5 g/cm3, significantly higher than aluminum alloys' average density of 2.7 g/cm3, which impacts overall component mass and design considerations. Despite titanium's greater density, its enhanced mechanical properties allow for thinner, lighter parts to be used without compromising structural integrity.

Strength-to-Weight Ratio Analysis

Titanium alloys exhibit a superior strength-to-weight ratio compared to aluminum alloys, making them ideal for aerospace and high-performance automotive applications where minimizing weight without sacrificing strength is critical. The density of titanium alloys ranges around 4.43 g/cm3, significantly higher than aluminum alloys at approximately 2.7 g/cm3, but their tensile strength often exceeds aluminum by a factor of two to three. This combination of high strength and moderate weight allows titanium alloys to deliver enhanced structural performance under demanding conditions while enabling weight savings essential for fuel efficiency and durability.

Corrosion Resistance Comparison

Titanium alloys exhibit superior corrosion resistance compared to aluminum alloys due to the stable and protective oxide layer that forms on their surface, which effectively prevents oxidation in aggressive environments. Aluminum alloys are more prone to corrosion, especially in marine or chloride-rich environments, where pitting and galvanic corrosion can occur. The enhanced durability of titanium alloys makes them ideal for applications requiring long-term exposure to harsh chemicals or seawater.

Cost and Availability Factors

Titanium alloys are significantly more expensive than aluminum alloys due to complex extraction and processing methods, impacting overall project budgets. Aluminum alloys benefit from widespread availability and mature manufacturing infrastructure, making them more cost-effective for large-scale applications. Limited global titanium supply and high demand in aerospace and medical industries further constrain availability and elevate prices.

Applications in Aerospace and Automotive Industries

Titanium alloys are preferred in aerospace applications for their exceptional strength-to-weight ratio, corrosion resistance, and high-temperature performance, making them ideal for aircraft structural components and engine parts. Aluminum alloys dominate automotive manufacturing due to their lightweight nature, cost-effectiveness, and good corrosion resistance, enhancing fuel efficiency and vehicle performance. Both materials contribute significantly to the aerospace and automotive industries by optimizing weight reduction, durability, and overall efficiency.

Machinability and Fabrication Challenges

Titanium alloys exhibit lower machinability compared to aluminum alloys due to their higher strength, toughness, and tendency to work-harden, resulting in increased tool wear and slower cutting speeds. Fabrication challenges with titanium alloys include difficulty in welding because of their reactive nature at elevated temperatures and the need for specialized equipment to prevent contamination and oxidation. Aluminum alloys, by contrast, offer superior machinability and easier fabrication processes, making them more cost-effective for applications requiring intricate machining and mass production.

Sustainability and Environmental Impact

Titanium alloys exhibit superior sustainability compared to aluminum alloys due to their longer lifespan and higher corrosion resistance, which reduces the frequency of replacements and associated waste. The production of titanium alloys typically generates lower carbon emissions per unit strength, contributing to a decreased environmental footprint. Furthermore, titanium's excellent recyclability supports circular economy practices, minimizing the environmental impact linked to raw material extraction.

Titanium alloy vs Aluminum alloy Infographic

materialdif.com

materialdif.com