Precipitation hardening enhances alloy strength by forming fine particles that hinder dislocation movement, whereas solution annealing dissolves these particles to create a uniform solid solution, improving ductility and corrosion resistance. Precipitation hardening involves heating and aging to precipitate strengthening phases, while solution annealing requires heating followed by rapid cooling to retain a single-phase microstructure. Understanding the balance between these processes is essential for tailoring mechanical properties in aluminum and stainless steel alloys.

Table of Comparison

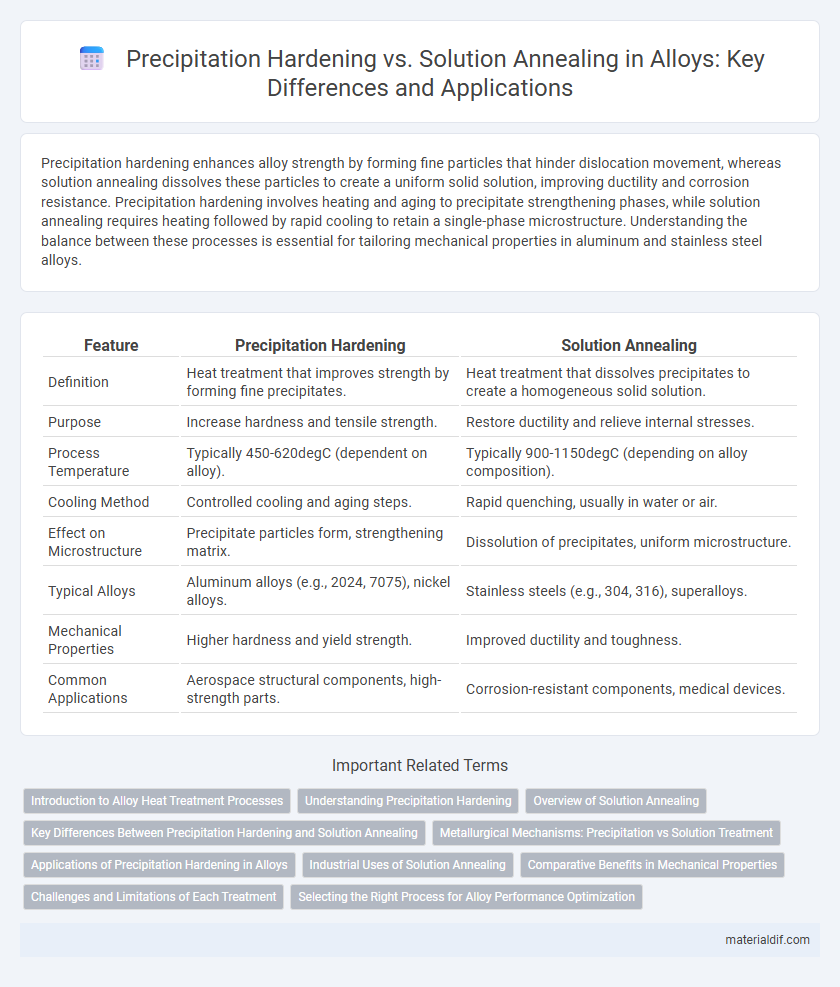

| Feature | Precipitation Hardening | Solution Annealing |

|---|---|---|

| Definition | Heat treatment that improves strength by forming fine precipitates. | Heat treatment that dissolves precipitates to create a homogeneous solid solution. |

| Purpose | Increase hardness and tensile strength. | Restore ductility and relieve internal stresses. |

| Process Temperature | Typically 450-620degC (dependent on alloy). | Typically 900-1150degC (depending on alloy composition). |

| Cooling Method | Controlled cooling and aging steps. | Rapid quenching, usually in water or air. |

| Effect on Microstructure | Precipitate particles form, strengthening matrix. | Dissolution of precipitates, uniform microstructure. |

| Typical Alloys | Aluminum alloys (e.g., 2024, 7075), nickel alloys. | Stainless steels (e.g., 304, 316), superalloys. |

| Mechanical Properties | Higher hardness and yield strength. | Improved ductility and toughness. |

| Common Applications | Aerospace structural components, high-strength parts. | Corrosion-resistant components, medical devices. |

Introduction to Alloy Heat Treatment Processes

Precipitation hardening enhances alloy strength by forming fine, uniformly distributed particles through controlled cooling and aging, improving mechanical properties. Solution annealing dissolves alloying elements into a solid solution by heating followed by rapid quenching, restoring ductility and homogenizing the microstructure. These distinct heat treatment processes are crucial for tailoring the performance characteristics of aluminum, titanium, and nickel-based superalloys in aerospace and industrial applications.

Understanding Precipitation Hardening

Precipitation hardening enhances alloy strength by forming fine, dispersed particles within the metal matrix that impede dislocation motion, significantly increasing hardness and yield strength. This process involves solution treatment followed by rapid quenching and controlled aging to nucleate and grow precipitates, optimizing mechanical properties. Understanding precipitation hardening mechanisms is critical for tailoring alloy compositions and heat treatments to achieve superior performance in aerospace, automotive, and structural applications.

Overview of Solution Annealing

Solution annealing is a heat treatment process used to homogenize alloying elements within the metal matrix, typically heating the alloy to a temperature where elements dissolve into a solid solution. This process eliminates coarse precipitates and improves corrosion resistance by creating a uniform microstructure. It is commonly applied to stainless steel alloys to restore ductility and prepare the material for subsequent precipitation hardening steps.

Key Differences Between Precipitation Hardening and Solution Annealing

Precipitation hardening involves heating an alloy to form fine particles that strengthen the metal, improving hardness and tensile strength. Solution annealing dissolves precipitates by heating the alloy to a single-phase region, followed by rapid cooling to create a uniform solid solution and restore ductility. Key differences lie in their purposes: precipitation hardening increases strength through controlled precipitation, while solution annealing focuses on softening and homogenizing the microstructure.

Metallurgical Mechanisms: Precipitation vs Solution Treatment

Precipitation hardening enhances alloy strength by forming finely dispersed intermetallic particles during controlled cooling, which obstruct dislocation motion and improve mechanical properties. Solution annealing dissolves alloying elements into a solid solution at high temperatures, homogenizing the microstructure and relieving internal stresses without precipitate formation. The key metallurgical difference lies in precipitation hardening promoting controlled particle nucleation, while solution annealing ensures a uniform single-phase matrix for subsequent treatments.

Applications of Precipitation Hardening in Alloys

Precipitation hardening enhances alloy strength by forming fine, uniformly distributed particles that impede dislocation motion, making it ideal for aerospace and automotive components requiring high strength-to-weight ratios. This heat treatment process is commonly applied to aluminum, titanium, and nickel-based superalloys used in jet engines and structural aircraft parts. Compared to solution annealing, precipitation hardening provides improved mechanical properties such as increased yield strength and hardness, critical for performance in demanding environments.

Industrial Uses of Solution Annealing

Solution annealing is widely utilized in industries requiring enhanced corrosion resistance and structural stability, such as aerospace, chemical processing, and nuclear sectors. This heat treatment process dissolves precipitates to form a uniform solid solution, improving alloy ductility and toughness essential for manufacturing high-performance stainless steel components. Unlike precipitation hardening, solution annealing enables critical reprocessing of alloys to restore corrosion resistance after welding or cold working in industrial applications.

Comparative Benefits in Mechanical Properties

Precipitation hardening significantly enhances yield strength and tensile strength by forming finely dispersed precipitates that impede dislocation motion, whereas solution annealing primarily improves ductility and toughness by dissolving alloying elements into a homogeneous solid solution. The increased hardness and fatigue resistance achieved through precipitation hardening make it ideal for high-stress applications, while solution annealed alloys offer superior corrosion resistance and formability. Selecting between these heat treatments depends on the desired balance of mechanical properties for specific alloy systems like aluminum, titanium, or nickel-based superalloys.

Challenges and Limitations of Each Treatment

Precipitation hardening enhances alloy strength by forming fine particles that hinder dislocation movement, but its effectiveness is limited by the risk of over-aging and non-uniform particle distribution, which can reduce toughness and corrosion resistance. Solution annealing dissolves precipitates to restore alloy ductility and homogenize the microstructure, yet it often struggles with grain growth and incomplete dissolution of secondary phases, leading to mechanical inconsistencies. Both treatments require precise temperature and time control to balance mechanical properties, with challenges in scaling processes and maintaining microstructural stability under varying service conditions.

Selecting the Right Process for Alloy Performance Optimization

Precipitation hardening enhances alloy strength by forming fine particles that impede dislocation movement, ideal for applications requiring high tensile strength and hardness. Solution annealing dissolves precipitates to restore ductility and corrosion resistance, making it suitable for alloys subjected to cyclic stress or harsh environments. Selecting the appropriate process depends on balancing mechanical properties with service conditions, ensuring optimal performance through tailored microstructural control.

Precipitation Hardening vs Solution Annealing Infographic

materialdif.com

materialdif.com