Alloy 20 offers superior corrosion resistance in sulfuric acid environments compared to Alloy 825, making it ideal for chemical processing applications. While both alloys provide excellent strength and durability, Alloy 20 contains higher amounts of nickel and molybdenum, enhancing its resistance to pitting and crevice corrosion. Alloy 825, however, is often preferred for applications requiring higher resistance to stress corrosion cracking and for use in environments containing chlorides.

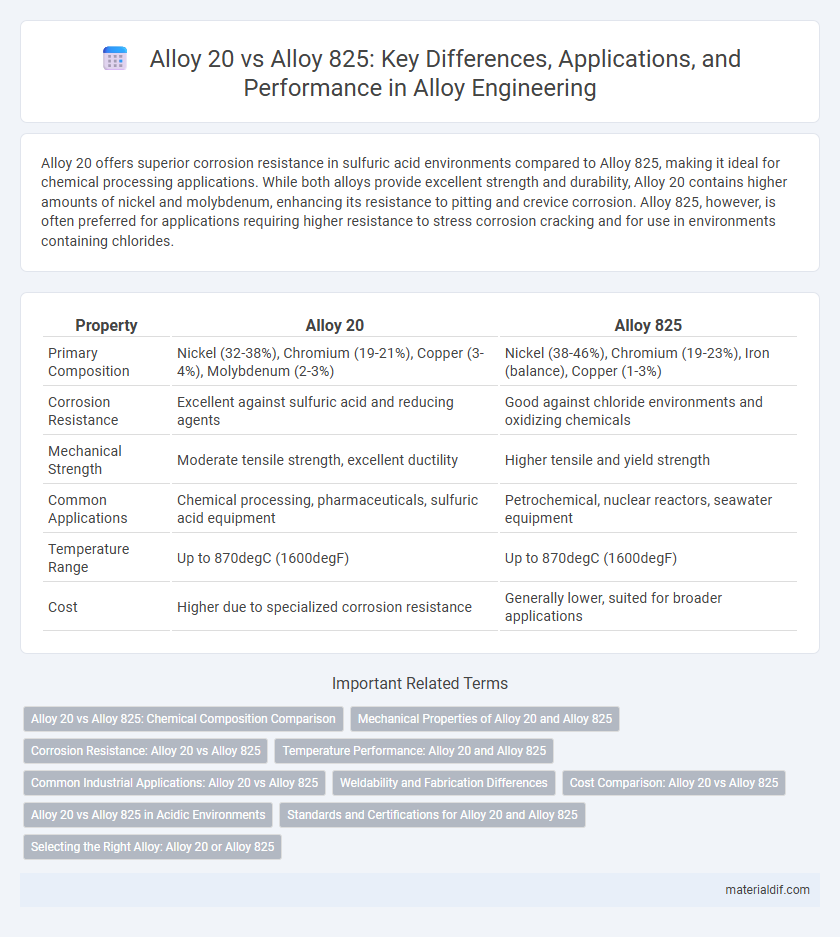

Table of Comparison

| Property | Alloy 20 | Alloy 825 |

|---|---|---|

| Primary Composition | Nickel (32-38%), Chromium (19-21%), Copper (3-4%), Molybdenum (2-3%) | Nickel (38-46%), Chromium (19-23%), Iron (balance), Copper (1-3%) |

| Corrosion Resistance | Excellent against sulfuric acid and reducing agents | Good against chloride environments and oxidizing chemicals |

| Mechanical Strength | Moderate tensile strength, excellent ductility | Higher tensile and yield strength |

| Common Applications | Chemical processing, pharmaceuticals, sulfuric acid equipment | Petrochemical, nuclear reactors, seawater equipment |

| Temperature Range | Up to 870degC (1600degF) | Up to 870degC (1600degF) |

| Cost | Higher due to specialized corrosion resistance | Generally lower, suited for broader applications |

Alloy 20 vs Alloy 825: Chemical Composition Comparison

Alloy 20 primarily consists of iron, nickel (30-35%), chromium (19-21%), and significant amounts of copper (2.5-3.5%) with molybdenum (2-3%) to enhance corrosion resistance in acidic environments. Alloy 825 features iron, nickel (38-46%), chromium (19.5-23.5%), molybdenum (2.5-3.5%), and small cobalt additions, providing high strength and resistance to oxidation and stress corrosion cracking. The key difference lies in Alloy 20's higher copper content for superior resistance to sulfuric acid, while Alloy 825's higher nickel and cobalt improve performance in more aggressive mixed acid and oxidizing environments.

Mechanical Properties of Alloy 20 and Alloy 825

Alloy 20 exhibits tensile strength ranging from 550 to 860 MPa and demonstrates excellent ductility with elongation typically between 30-40%, making it well-suited for corrosion-resistant applications. Alloy 825 offers a tensile strength of approximately 585-860 MPa and yield strength around 275-415 MPa, with elongation values also ranging near 30%, providing robust mechanical performance in acidic environments. Both alloys show good toughness, but Alloy 20 is preferred for its superior resistance to sulfuric acid while Alloy 825 maintains strength in high-temperature and reducing conditions.

Corrosion Resistance: Alloy 20 vs Alloy 825

Alloy 20 exhibits superior corrosion resistance compared to Alloy 825, particularly in sulfuric acid environments, due to its high nickel, chromium, and molybdenum content. Alloy 20 resists pitting, crevice corrosion, and stress corrosion cracking better than Alloy 825, making it ideal for chemical processing applications. In contrast, Alloy 825 performs well in a broader range of reducing and oxidizing environments but lacks the specialized resistance of Alloy 20 in highly corrosive acidic media.

Temperature Performance: Alloy 20 and Alloy 825

Alloy 20 offers excellent corrosion resistance and stability at temperatures up to 600degF, making it suitable for high-temperature industrial environments. Alloy 825 performs well in temperatures ranging from cryogenic levels up to about 1500degF, with superior strength retention and resistance to oxidation. Compared to Alloy 20, Alloy 825 provides a broader temperature range and enhanced mechanical performance in extreme thermal conditions.

Common Industrial Applications: Alloy 20 vs Alloy 825

Alloy 20 finds extensive use in chemical processing industries, especially in sulfuric acid, phosphoric acid, and acetic acid environments due to its superior resistance to strong reducing agents. Alloy 825 is commonly utilized in oil and gas, marine, and nuclear sectors, favored for its excellent corrosion resistance in chloride environments and high-strength properties. Both alloys serve critical roles in heat exchangers, storage tanks, and piping systems, with Alloy 20 preferred for acidic solutions and Alloy 825 for environments with seawater exposure and high-temperature corrosion concerns.

Weldability and Fabrication Differences

Alloy 20 offers superior weldability compared to Alloy 825, owing to its stable austenitic structure that minimizes intergranular attack and weld decay, making it highly suitable for sulfuric acid applications. In fabrication, Alloy 20 requires careful control of heat input during welding to avoid carbide precipitation, whereas Alloy 825, with its nickel-iron-chromium composition, exhibits better weld heat resistance but may be prone to stress corrosion cracking in certain environments. The distinct metallurgical differences between Alloy 20 and Alloy 825 influence their performance in welded joints, impacting their selection for chemical processing equipment.

Cost Comparison: Alloy 20 vs Alloy 825

Alloy 20 typically incurs higher material and fabrication costs compared to Alloy 825 due to its enhanced corrosion resistance and superior mechanical properties. While Alloy 825 offers a more cost-effective solution for moderate chemical environments, Alloy 20's premium pricing is justified in aggressive conditions requiring exceptional resistance to sulfuric acid and chloride stress corrosion. Choosing between Alloy 20 and Alloy 825 depends on balancing upfront costs against long-term durability and maintenance savings in targeted applications.

Alloy 20 vs Alloy 825 in Acidic Environments

Alloy 20 exhibits superior resistance to nitric, sulfuric, and phosphoric acids compared to Alloy 825, making it ideal for harsh acidic environments. Its high nickel and molybdenum content enhances corrosion resistance and prevents acid attack, especially in sulfuric acid applications. Alloy 825, while resistant to a broad range of environments, shows less tolerance in highly oxidizing and concentrated acidic conditions, limiting its use where Alloy 20 excels.

Standards and Certifications for Alloy 20 and Alloy 825

Alloy 20 complies with standards such as ASTM B462 for seamless and welded pipes, ASTM B463 for seamless and welded tubes, and AMS 5772 for forged bars, ensuring high corrosion resistance and quality. Alloy 825 meets specifications including ASTM B446 for seamless pipes, ASTM B443 for plates, and UNS N08825, emphasizing its strength and resistance in harsh environments. Both alloys hold certifications that align with international standards like ASME SA and SB codes, confirming their suitability for use in chemical processing and aerospace industries.

Selecting the Right Alloy: Alloy 20 or Alloy 825

Alloy 20 offers superior resistance to sulfuric acid and general corrosion, making it ideal for chemical processing environments involving strong acids. Alloy 825 excels in resistance to reducing agents, high temperature oxidation, and stress corrosion cracking, suitable for offshore and nuclear applications. Selecting between Alloy 20 and Alloy 825 depends on the specific chemical exposure and mechanical stress conditions of the intended application.

Alloy 20 vs Alloy 825 Infographic

materialdif.com

materialdif.com