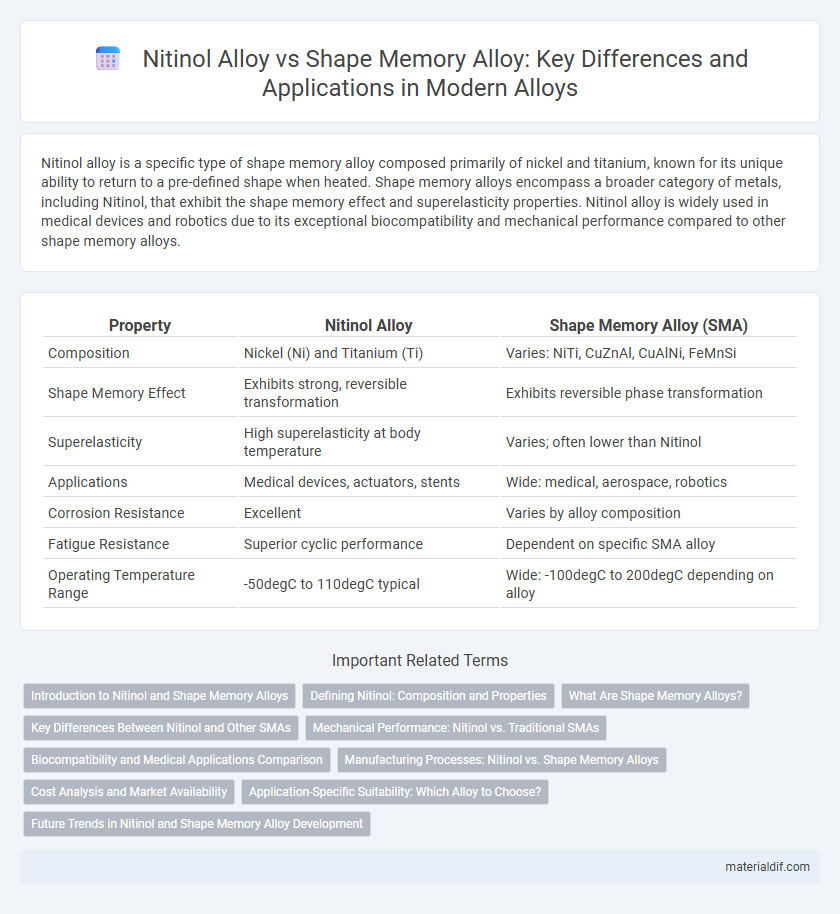

Nitinol alloy is a specific type of shape memory alloy composed primarily of nickel and titanium, known for its unique ability to return to a pre-defined shape when heated. Shape memory alloys encompass a broader category of metals, including Nitinol, that exhibit the shape memory effect and superelasticity properties. Nitinol alloy is widely used in medical devices and robotics due to its exceptional biocompatibility and mechanical performance compared to other shape memory alloys.

Table of Comparison

| Property | Nitinol Alloy | Shape Memory Alloy (SMA) |

|---|---|---|

| Composition | Nickel (Ni) and Titanium (Ti) | Varies: NiTi, CuZnAl, CuAlNi, FeMnSi |

| Shape Memory Effect | Exhibits strong, reversible transformation | Exhibits reversible phase transformation |

| Superelasticity | High superelasticity at body temperature | Varies; often lower than Nitinol |

| Applications | Medical devices, actuators, stents | Wide: medical, aerospace, robotics |

| Corrosion Resistance | Excellent | Varies by alloy composition |

| Fatigue Resistance | Superior cyclic performance | Dependent on specific SMA alloy |

| Operating Temperature Range | -50degC to 110degC typical | Wide: -100degC to 200degC depending on alloy |

Introduction to Nitinol and Shape Memory Alloys

Nitinol is a nickel-titanium alloy renowned for its exceptional shape memory and superelastic properties, making it a prominent subset of shape memory alloys (SMAs). Shape memory alloys, including Nitinol, can undergo deformation and return to their original shape upon heating due to phase transformations between martensite and austenite structures. These unique properties drive applications in medical devices, actuators, and smart materials, with Nitinol being the most widely studied and commercially used SMA due to its biocompatibility and reliable performance.

Defining Nitinol: Composition and Properties

Nitinol alloy, primarily composed of approximately 55% nickel and 45% titanium, is a distinctive type of shape memory alloy renowned for its exceptional superelasticity and shape memory properties. This unique composition enables Nitinol to undergo deformation and return to its original shape when heated above its transformation temperature. Its biocompatibility and corrosion resistance make Nitinol particularly valuable in medical devices and actuators within various engineering applications.

What Are Shape Memory Alloys?

Shape Memory Alloys (SMAs) are a unique class of metallic materials that can return to their original shape after deformation when exposed to a specific temperature. Nitinol, an alloy of nickel and titanium, is one of the most well-known and widely used SMAs due to its exceptional shape memory effect and superelasticity. These alloys have critical applications in medical devices, actuators, and robotics, leveraging their ability to undergo reversible phase transformations between martensite and austenite phases.

Key Differences Between Nitinol and Other SMAs

Nitinol Alloy distinguishes itself from other Shape Memory Alloys (SMAs) primarily through its unique composition of nickel and titanium, granting it superior biocompatibility and corrosion resistance crucial for medical applications. Unlike other SMAs, Nitinol exhibits a narrow hysteresis and a precise transformation temperature range, enabling highly predictable and repeatable shape memory and superelastic behaviors. Its exceptional fatigue resistance also sets it apart, making it ideal for dynamic environments such as stents and actuators where long-term cyclic loading is expected.

Mechanical Performance: Nitinol vs. Traditional SMAs

Nitinol exhibits superior mechanical performance compared to traditional shape memory alloys (SMAs) due to its exceptional elasticity and fatigue resistance, enabling repeated strain cycles without permanent deformation. Its unique composition of nearly equal parts nickel and titanium provides high strength and remarkable recovery stress, outperforming conventional SMAs such as copper-based or iron-based alloys. These characteristics make Nitinol ideal for applications demanding high durability and precise shape recovery under mechanical stress.

Biocompatibility and Medical Applications Comparison

Nitinol alloy, a specific type of shape memory alloy (SMA), exhibits superior biocompatibility due to its nickel-titanium composition, making it highly suitable for medical applications such as stents, orthodontic wires, and surgical tools. Shape memory alloys in general offer unique properties like superelasticity and the ability to return to a preset shape, but Nitinol is uniquely favored in implantable devices because of its corrosion resistance and minimal cytotoxicity. Biocompatibility assessments consistently show that Nitinol outperforms other SMAs, enabling widespread use in cardiovascular and orthopedic medical devices.

Manufacturing Processes: Nitinol vs. Shape Memory Alloys

Nitinol, a specific type of shape memory alloy composed primarily of nickel and titanium, undergoes unique manufacturing processes including vacuum induction melting and thermomechanical treatments to optimize its superelasticity and shape memory properties. In contrast, other shape memory alloys, such as copper-based or iron-based varieties, typically involve different alloying elements and may use casting, rolling, or specialized heat treatments tailored to their distinct phase transformation characteristics. Precise control of processing parameters like temperature and cooling rates in Nitinol manufacturing is critical to achieving its biocompatibility and functional performance in medical and industrial applications.

Cost Analysis and Market Availability

Nitinol alloy, a widely used type of shape memory alloy (SMA), generally proves more cost-effective due to its established production processes and broad market availability. Other shape memory alloys, such as copper-based or iron-based SMAs, often exhibit lower raw material costs but face higher processing expenses and limited commercial supply. Market availability of Nitinol is robust worldwide, supporting diverse medical and industrial applications, whereas alternative SMAs have niche markets with fluctuating accessibility and pricing structures.

Application-Specific Suitability: Which Alloy to Choose?

Nitinol alloy's unique combination of high corrosion resistance and biocompatibility makes it ideal for medical devices such as stents and orthodontic wires. Shape memory alloys overall provide tailored mechanical properties and thermal activation suitable for aerospace actuators and robotics. Selecting between Nitinol and other shape memory alloys depends on the specific application requirements including operating temperature range, fatigue resistance, and environmental compatibility.

Future Trends in Nitinol and Shape Memory Alloy Development

Nitinol alloy, a prominent type of shape memory alloy (SMA), is rapidly advancing with innovations in biocompatibility and fatigue resistance, enabling broader applications in medical implants and robotic actuators. Future trends emphasize nano-engineering and additive manufacturing techniques to enhance the precision and performance of SMAs, particularly Nitinol, in adaptive structures and smart materials. Research in multi-functional SMAs integrates sensing and actuation capabilities, driving the evolution of next-generation smart devices and wearable technologies.

Nitinol Alloy vs Shape Memory Alloy Infographic

materialdif.com

materialdif.com