Superalloys exhibit exceptional strength, corrosion resistance, and stability at high temperatures, making them ideal for aerospace, power generation, and chemical processing applications. Standard alloys, while more cost-effective and easier to manufacture, often lack the advanced mechanical properties and oxidation resistance required for extreme environments. The choice between superalloy and standard alloy depends on the specific performance demands and economic considerations of the intended application.

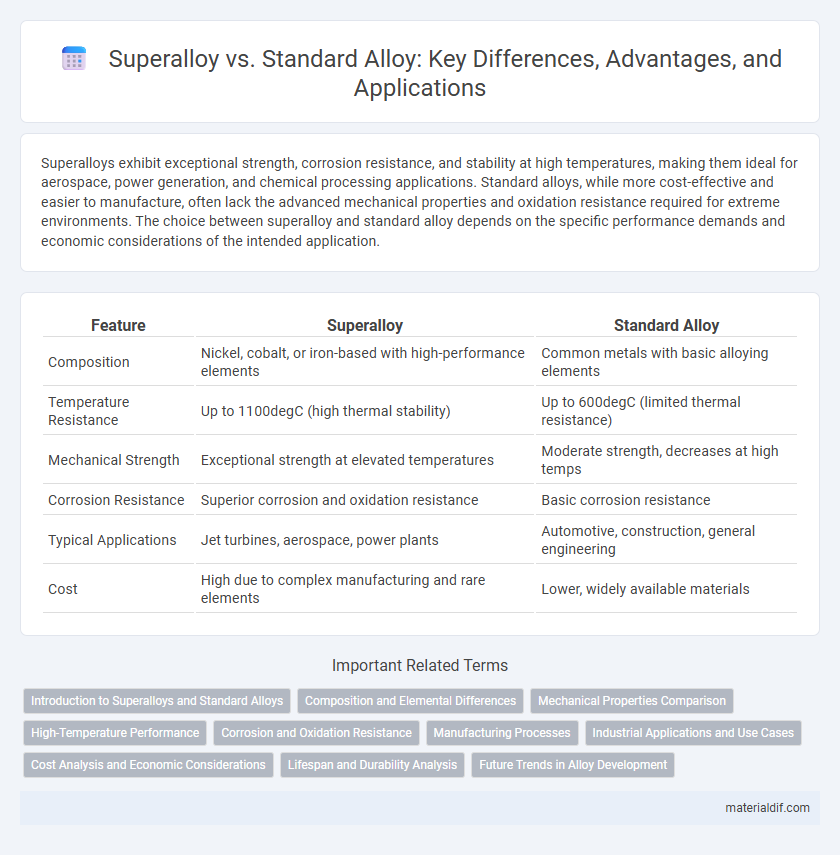

Table of Comparison

| Feature | Superalloy | Standard Alloy |

|---|---|---|

| Composition | Nickel, cobalt, or iron-based with high-performance elements | Common metals with basic alloying elements |

| Temperature Resistance | Up to 1100degC (high thermal stability) | Up to 600degC (limited thermal resistance) |

| Mechanical Strength | Exceptional strength at elevated temperatures | Moderate strength, decreases at high temps |

| Corrosion Resistance | Superior corrosion and oxidation resistance | Basic corrosion resistance |

| Typical Applications | Jet turbines, aerospace, power plants | Automotive, construction, general engineering |

| Cost | High due to complex manufacturing and rare elements | Lower, widely available materials |

Introduction to Superalloys and Standard Alloys

Superalloys are advanced metal alloys designed for high-performance applications, exhibiting exceptional mechanical strength, resistance to thermal creep deformation, and corrosion resistance at elevated temperatures. Standard alloys, in contrast, are common metal mixtures optimized primarily for general durability and cost-efficiency but lack the enhanced high-temperature properties found in superalloys. The unique composition of superalloys, typically based on nickel, cobalt, or iron, enables their use in aerospace, power generation, and automotive industries requiring superior performance under extreme conditions.

Composition and Elemental Differences

Superalloys contain higher concentrations of nickel, cobalt, and chromium, enhancing their heat resistance and mechanical strength compared to standard alloys primarily made of iron, carbon, and minor alloying elements. The elemental composition of superalloys often includes significant amounts of aluminum and titanium to improve oxidation resistance and precipitation hardening, whereas standard alloys lack these advanced constituents. These compositional differences result in superalloys maintaining structural integrity at elevated temperatures, unlike standard alloys designed for less extreme environments.

Mechanical Properties Comparison

Superalloys offer superior mechanical properties compared to standard alloys, including higher tensile strength and enhanced creep resistance at elevated temperatures. Their microstructure is specifically engineered for stability under extreme thermal and mechanical stress, making them ideal for aerospace and power generation applications. Standard alloys generally exhibit lower fatigue life and reduced hardness, limiting their use in high-performance environments.

High-Temperature Performance

Superalloys exhibit superior high-temperature performance compared to standard alloys due to their enhanced oxidation resistance and mechanical strength at elevated temperatures above 1000degC. They maintain structural integrity under thermal stress and resist creep deformation, making them essential in aerospace turbines and power generation industries. Standard alloys typically degrade faster under similar conditions, limiting their use in extreme environments.

Corrosion and Oxidation Resistance

Superalloys exhibit superior corrosion and oxidation resistance compared to standard alloys due to their high levels of chromium, nickel, and aluminum, which form stable oxide layers protecting the material under extreme temperatures and oxidative environments. Standard alloys generally lack the specialized elemental composition and microstructural stability, making them more susceptible to surface degradation, pitting, and scaling in aggressive conditions. The enhanced performance of superalloys in harsh environments makes them the material of choice for aerospace, power generation, and chemical processing industries where longevity and reliability are critical.

Manufacturing Processes

Superalloys undergo advanced manufacturing processes such as vacuum arc remelting (VAR) and directional solidification to enhance their microstructure and high-temperature performance. Standard alloys typically utilize conventional casting and forging techniques, which are less complex but offer adequate mechanical properties for general applications. The precise control in superalloy manufacturing improves creep resistance and corrosion tolerance critical for aerospace and turbine engine components.

Industrial Applications and Use Cases

Superalloys exhibit superior resistance to high temperatures, corrosion, and mechanical stress, making them ideal for aerospace turbine engines, gas turbines, and nuclear reactors where extreme environments prevail. Standard alloys, while cost-effective and easier to manufacture, are commonly used in automotive parts, construction materials, and consumer electronics where moderate strength and corrosion resistance suffice. The choice between superalloy and standard alloy hinges on the specific industrial application requirements regarding thermal stability, durability, and economic considerations.

Cost Analysis and Economic Considerations

Superalloys typically exhibit higher initial costs due to expensive raw materials like nickel, cobalt, and molybdenum, alongside complex manufacturing processes involving precise control of microstructure and heat treatment. Standard alloys, often made from more abundant and less costly metals such as iron or aluminum, offer economic advantages for applications with lower performance demands, reducing overall production and maintenance expenses. Evaluating the total cost of ownership, including lifespan, performance under extreme conditions, and resistance to corrosion and fatigue, is crucial for choosing between superalloys and standard alloys in industrial applications.

Lifespan and Durability Analysis

Superalloys exhibit significantly higher lifespan and durability compared to standard alloys due to their enhanced resistance to oxidation, corrosion, and high-temperature deformation. The microstructural stability of superalloys under extreme thermal and mechanical stresses ensures minimal degradation over extended service periods. These properties make superalloys the preferred choice for critical aerospace, power generation, and industrial applications where longevity and reliability are paramount.

Future Trends in Alloy Development

Future trends in alloy development emphasize enhancing the high-temperature performance and corrosion resistance of superalloys compared to standard alloys. Research on advancing nanostructured superalloys and incorporating additive manufacturing techniques aims to achieve superior mechanical properties and extended service life. Integration of sustainable materials and AI-driven alloy design accelerates innovation in next-generation superalloys for aerospace and energy applications.

Superalloy vs Standard Alloy Infographic

materialdif.com

materialdif.com