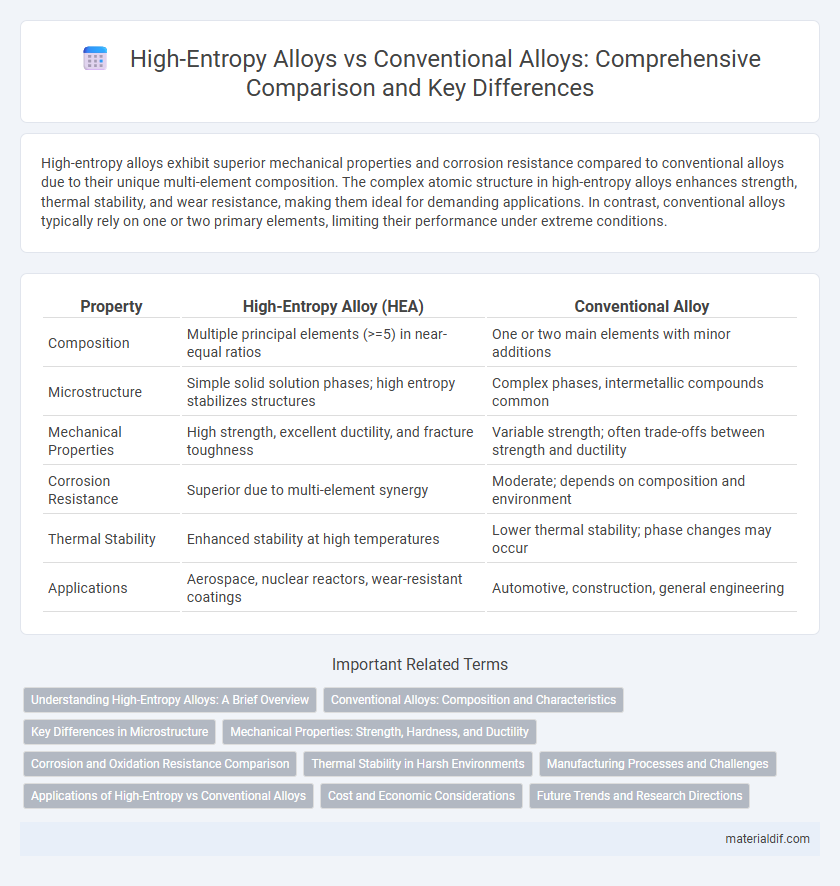

High-entropy alloys exhibit superior mechanical properties and corrosion resistance compared to conventional alloys due to their unique multi-element composition. The complex atomic structure in high-entropy alloys enhances strength, thermal stability, and wear resistance, making them ideal for demanding applications. In contrast, conventional alloys typically rely on one or two primary elements, limiting their performance under extreme conditions.

Table of Comparison

| Property | High-Entropy Alloy (HEA) | Conventional Alloy |

|---|---|---|

| Composition | Multiple principal elements (>=5) in near-equal ratios | One or two main elements with minor additions |

| Microstructure | Simple solid solution phases; high entropy stabilizes structures | Complex phases, intermetallic compounds common |

| Mechanical Properties | High strength, excellent ductility, and fracture toughness | Variable strength; often trade-offs between strength and ductility |

| Corrosion Resistance | Superior due to multi-element synergy | Moderate; depends on composition and environment |

| Thermal Stability | Enhanced stability at high temperatures | Lower thermal stability; phase changes may occur |

| Applications | Aerospace, nuclear reactors, wear-resistant coatings | Automotive, construction, general engineering |

Understanding High-Entropy Alloys: A Brief Overview

High-entropy alloys (HEAs) consist of five or more principal elements in near-equiatomic proportions, distinct from conventional alloys that typically rely on one primary element with minor additions. This multi-element composition enhances configurational entropy, resulting in remarkable mechanical strength, corrosion resistance, and thermal stability. Ongoing research emphasizes HEAs' potential for advanced engineering applications due to their unique microstructural properties and phase stability.

Conventional Alloys: Composition and Characteristics

Conventional alloys typically consist of one principal metal combined with smaller amounts of other elements to enhance specific mechanical and chemical properties. These alloys exhibit well-defined microstructures, such as austenite or ferrite phases in steel, which contribute to predictable behavior under various environmental conditions. Their compositions are optimized for targeted applications, balancing factors like strength, ductility, corrosion resistance, and cost-effectiveness.

Key Differences in Microstructure

High-entropy alloys (HEAs) typically exhibit a simple microstructure with multiple principal elements forming a single solid solution phase, contrasting with conventional alloys that often contain complex microstructures with multiple intermetallic compounds and phases. The high configurational entropy in HEAs stabilizes disordered solid solutions, enhancing mechanical properties such as strength and corrosion resistance. Conventional alloys rely on phase segregation and precipitate strengthening mechanisms, resulting in distinctly heterogeneous microstructures compared to the homogeneous nature of HEAs.

Mechanical Properties: Strength, Hardness, and Ductility

High-entropy alloys (HEAs) demonstrate superior mechanical properties compared to conventional alloys, exhibiting outstanding strength and hardness due to their multi-principal element composition that promotes complex microstructures and solid solution strengthening. Despite their high strength, HEAs maintain notable ductility, balancing rigidity and deformability better than many traditional alloys that often sacrifice ductility for strength. The unique combination of strength, hardness, and ductility in HEAs makes them ideal candidates for advanced applications requiring durable yet flexible materials.

Corrosion and Oxidation Resistance Comparison

High-entropy alloys (HEAs) exhibit superior corrosion and oxidation resistance compared to conventional alloys due to their unique multi-element compositions that form stable, protective oxide layers. These alloys often demonstrate enhanced passivation behavior and resistance to pitting and crevice corrosion in aggressive environments. The high configurational entropy in HEAs stabilizes complex microstructures that inhibit diffusion processes, significantly improving long-term durability against oxidative degradation.

Thermal Stability in Harsh Environments

High-entropy alloys exhibit superior thermal stability in harsh environments compared to conventional alloys due to their multi-principal element compositions, which enhance phase stability and resistance to grain growth at elevated temperatures. The complex atomic-scale interactions in high-entropy alloys reduce diffusion rates, minimizing oxidation and creep deformation under extreme thermal stress. Consequently, these alloys maintain mechanical integrity and corrosion resistance in environments exceeding 1000degC, outperforming traditional single or binary metal systems.

Manufacturing Processes and Challenges

High-entropy alloys (HEAs) require advanced manufacturing techniques such as additive manufacturing, rapid solidification, and powder metallurgy to ensure uniform microstructure and phase distribution, which are critical for their superior properties. Conventional alloys often utilize traditional casting and forging processes that are optimized for single or limited element compositions but may struggle with defects like segregation and grain boundary weaknesses when applied to multi-element HEAs. Challenges in HEA manufacturing include controlling elemental homogeneity, managing complex phase stability, and addressing increased production costs due to the need for precise compositional control and specialized equipment.

Applications of High-Entropy vs Conventional Alloys

High-entropy alloys (HEAs) exhibit superior mechanical strength, corrosion resistance, and thermal stability, making them ideal for aerospace, nuclear reactors, and advanced manufacturing applications. Conventional alloys, typically composed of one principal element, dominate industries such as automotive and construction due to cost-effectiveness and established processing techniques. The unique multi-element composition of HEAs enables enhanced performance in extreme environments, surpassing the limitations of traditional alloys in critical high-stress applications.

Cost and Economic Considerations

High-entropy alloys (HEAs) often incur higher initial costs compared to conventional alloys due to complex multi-element compositions and advanced manufacturing processes. Conventional alloys benefit from established production techniques and abundant raw materials, resulting in lower material and processing expenses. Long-term economic considerations favor HEAs in high-performance applications where superior strength, corrosion resistance, and durability reduce maintenance and replacement costs.

Future Trends and Research Directions

High-entropy alloys (HEAs) exhibit unique microstructural stability and superior mechanical properties compared to conventional alloys, driving research toward their application in extreme environments and advanced manufacturing technologies. Future trends emphasize computational materials design, machine learning integration, and additive manufacturing to tailor HEA compositions and optimize performance for aerospace, energy, and biomedical sectors. Exploration of phase stability, corrosion resistance, and high-temperature behavior remains critical for expanding HEA industrial adoption and developing sustainable, high-performance materials.

High-entropy alloy vs Conventional alloy Infographic

materialdif.com

materialdif.com