Duplex stainless steel offers a balanced microstructure of austenite and ferrite, providing excellent corrosion resistance and good mechanical strength, ideal for moderate environments. Super duplex stainless steel contains higher levels of chromium, molybdenum, and nitrogen, resulting in superior corrosion resistance and increased strength, particularly in aggressive environments like offshore oil and gas applications. Choosing between duplex and super duplex grades depends on the specific corrosion challenges and mechanical demands of the application.

Table of Comparison

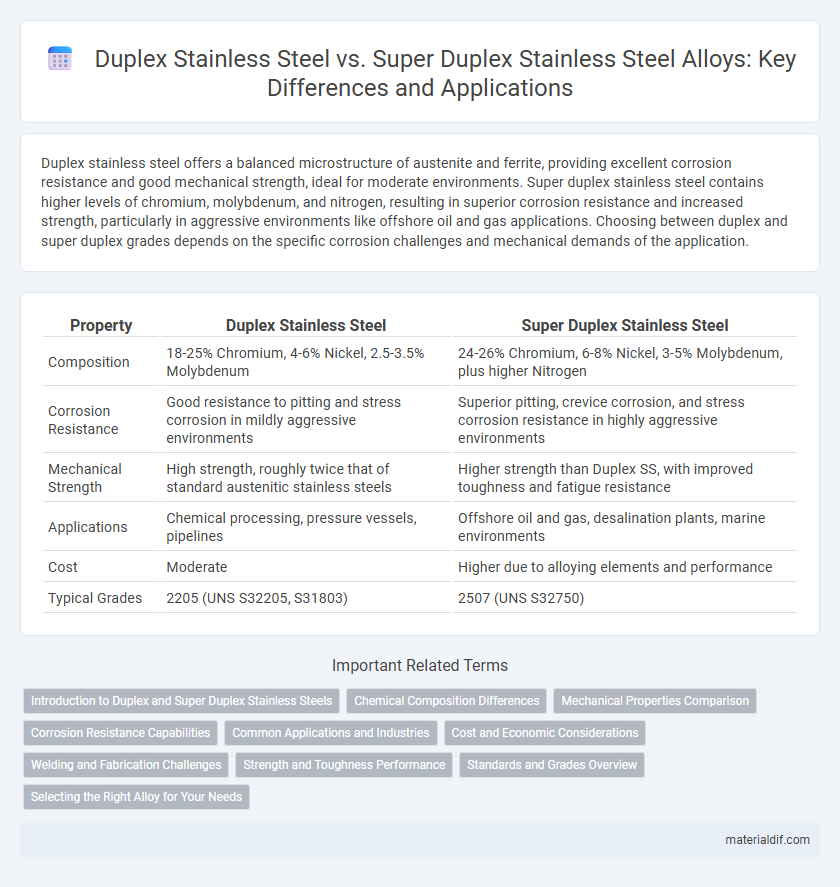

| Property | Duplex Stainless Steel | Super Duplex Stainless Steel |

|---|---|---|

| Composition | 18-25% Chromium, 4-6% Nickel, 2.5-3.5% Molybdenum | 24-26% Chromium, 6-8% Nickel, 3-5% Molybdenum, plus higher Nitrogen |

| Corrosion Resistance | Good resistance to pitting and stress corrosion in mildly aggressive environments | Superior pitting, crevice corrosion, and stress corrosion resistance in highly aggressive environments |

| Mechanical Strength | High strength, roughly twice that of standard austenitic stainless steels | Higher strength than Duplex SS, with improved toughness and fatigue resistance |

| Applications | Chemical processing, pressure vessels, pipelines | Offshore oil and gas, desalination plants, marine environments |

| Cost | Moderate | Higher due to alloying elements and performance |

| Typical Grades | 2205 (UNS S32205, S31803) | 2507 (UNS S32750) |

Introduction to Duplex and Super Duplex Stainless Steels

Duplex stainless steels combine the corrosion resistance of austenitic steels with the strength of ferritic steels, featuring a balanced microstructure typically composed of 50% ferrite and 50% austenite. Super duplex stainless steels enhance these properties with higher chromium, molybdenum, and nitrogen content, providing superior resistance to pitting, crevice corrosion, and stress corrosion cracking. Both materials are widely used in harsh environments such as chemical processing, oil and gas, and marine applications due to their excellent mechanical properties and corrosion resistance.

Chemical Composition Differences

Duplex stainless steel typically contains 22-25% chromium, 5-7% nickel, and 3-5% molybdenum, offering a balanced structure of austenite and ferrite phases. Super duplex stainless steel enhances this composition with 24-26% chromium, 6-8% nickel, and 3-5% molybdenum, along with higher levels of nitrogen (about 0.08-0.25%) to improve corrosion resistance and strength. The increased chromium and nitrogen in super duplex grades result in superior resistance to pitting, crevice corrosion, and stress corrosion cracking compared to standard duplex stainless steels.

Mechanical Properties Comparison

Duplex stainless steel exhibits tensile strength ranging from 485 to 620 MPa and offers excellent corrosion resistance with a balanced microstructure of austenite and ferrite phases. Super duplex stainless steel enhances mechanical properties with tensile strength often exceeding 750 MPa, improved yield strength, and superior resistance to stress corrosion cracking due to higher chromium, molybdenum, and nitrogen content. The increased phase balance and alloying elements in super duplex grades result in better toughness and higher mechanical durability under aggressive environments compared to standard duplex stainless steel.

Corrosion Resistance Capabilities

Duplex stainless steel offers excellent corrosion resistance, particularly against stress corrosion cracking and general corrosion in chloride environments. Super duplex stainless steel significantly enhances this capability by combining higher levels of chromium, molybdenum, and nitrogen, which results in superior resistance to pitting, crevice corrosion, and chloride-induced stress corrosion cracking. This makes super duplex stainless steel ideal for highly aggressive marine and chemical processing applications where long-term durability is critical.

Common Applications and Industries

Duplex stainless steel is commonly used in chemical processing, petrochemical equipment, and pressure vessels due to its excellent corrosion resistance and strength. Super duplex stainless steel finds extensive application in offshore oil and gas platforms, seawater desalination plants, and marine environments where higher stress and severe corrosion conditions prevail. Both alloys are favored in industries requiring durability against chloride-induced stress corrosion cracking and high mechanical performance.

Cost and Economic Considerations

Duplex stainless steel offers a cost-effective solution with moderate corrosion resistance and good mechanical properties, making it suitable for various industrial applications where budget constraints are significant. Super duplex stainless steel, while more expensive due to higher nickel and molybdenum content, provides superior corrosion resistance and strength, reducing maintenance and replacement costs over time. The initial investment in super duplex steel can be economically justified in highly corrosive environments, where long-term durability lowers total lifecycle costs.

Welding and Fabrication Challenges

Duplex stainless steel offers good weldability with moderate heat input control to prevent phase imbalance, while super duplex stainless steel demands stricter welding parameter controls to avoid sigma phase formation and maintain corrosion resistance. Both materials require precise filler metal selection and post-weld heat treatment considerations, but super duplex stainless steel's higher alloy content increases the risk of cracking and distortion during fabrication. Welding super duplex grades often involves greater complexity due to their sensitivity to thermal cycles and the need for rigorous procedural qualification.

Strength and Toughness Performance

Duplex stainless steel offers a balanced combination of strength and toughness, typically with tensile strengths around 620-850 MPa and excellent resistance to stress corrosion cracking. Super duplex stainless steel significantly outperforms standard duplex grades, boasting tensile strengths up to 1,100 MPa and enhanced toughness, making it ideal for harsher environments and higher mechanical stress applications. The microstructure of super duplex steel is optimized with higher ferrite and austenite content, improving its overall mechanical properties and corrosion resistance compared to standard duplex stainless steel.

Standards and Grades Overview

Duplex stainless steel is typically defined under standards such as ASTM A182 and A276, with grades like 2205 (UNS S32205) offering balanced corrosion resistance and mechanical strength. Super Duplex stainless steel meets more stringent standards including ASTM A790 and A240, featuring higher chromium, molybdenum, and nitrogen content in grades like 2507 (UNS S32750) for enhanced pitting and stress corrosion cracking resistance. These standards ensure specific chemical composition, microstructure, and mechanical properties tailored to demanding environments in oil and gas, chemical processing, and marine applications.

Selecting the Right Alloy for Your Needs

Duplex stainless steel offers a balanced microstructure with excellent corrosion resistance and strength, making it ideal for moderate environments. Super duplex stainless steel provides higher resistance to chloride stress corrosion cracking and greater strength, suited for aggressive marine and chemical applications. Selecting the right alloy depends on factors like chloride exposure, temperature, and mechanical stress to optimize performance and lifecycle costs.

Duplex Stainless Steel vs Super Duplex Stainless Steel Infographic

materialdif.com

materialdif.com