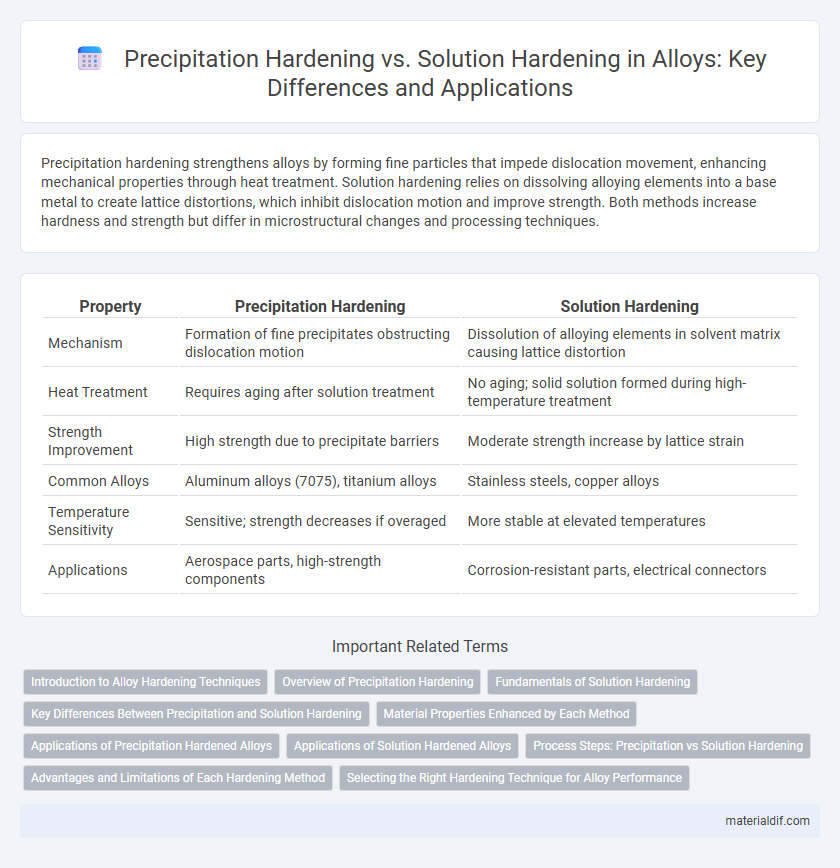

Precipitation hardening strengthens alloys by forming fine particles that impede dislocation movement, enhancing mechanical properties through heat treatment. Solution hardening relies on dissolving alloying elements into a base metal to create lattice distortions, which inhibit dislocation motion and improve strength. Both methods increase hardness and strength but differ in microstructural changes and processing techniques.

Table of Comparison

| Property | Precipitation Hardening | Solution Hardening |

|---|---|---|

| Mechanism | Formation of fine precipitates obstructing dislocation motion | Dissolution of alloying elements in solvent matrix causing lattice distortion |

| Heat Treatment | Requires aging after solution treatment | No aging; solid solution formed during high-temperature treatment |

| Strength Improvement | High strength due to precipitate barriers | Moderate strength increase by lattice strain |

| Common Alloys | Aluminum alloys (7075), titanium alloys | Stainless steels, copper alloys |

| Temperature Sensitivity | Sensitive; strength decreases if overaged | More stable at elevated temperatures |

| Applications | Aerospace parts, high-strength components | Corrosion-resistant parts, electrical connectors |

Introduction to Alloy Hardening Techniques

Precipitation hardening increases alloy strength by forming fine particles that impede dislocation motion, enhancing yield and tensile strength. Solution hardening strengthens alloys through the dissolution of alloying elements, creating lattice distortions that obstruct dislocation movement. Both techniques improve mechanical properties by manipulating microstructural features at the atomic level in metallic alloys.

Overview of Precipitation Hardening

Precipitation hardening, also known as age hardening, enhances alloy strength by forming finely dispersed secondary phase particles within the metal matrix through controlled heat treatment. This process generates coherent or semi-coherent precipitates that obstruct dislocation movement, significantly improving yield strength and hardness. Commonly applied in aluminum, titanium, and nickel-based alloys, precipitation hardening achieves superior mechanical properties compared to solution hardening by stabilizing microstructural features over time.

Fundamentals of Solution Hardening

Solution hardening strengthens alloys by dissolving impurity atoms directly into the metal matrix, creating lattice distortions that impede dislocation movement and enhance mechanical properties. This method relies on atomic size mismatch and differences in elastic modulus between solute and solvent atoms to generate internal stresses, increasing yield strength and hardness. Unlike precipitation hardening, solution hardening does not require second-phase particle formation but depends on maintaining a supersaturated solid solution for effective strengthening.

Key Differences Between Precipitation and Solution Hardening

Precipitation hardening enhances alloy strength by forming fine particles within the metal matrix through controlled heat treatment, which impedes dislocation movement more effectively than solution hardening. Solution hardening increases strength by dissolving alloying elements into the base metal to create a solid solution, causing lattice distortions that hinder dislocation motion but without the formation of secondary phases. Unlike solution hardening, precipitation hardening typically involves a multi-step process with aging to precipitate hard phases, resulting in superior hardness and tensile strength.

Material Properties Enhanced by Each Method

Precipitation hardening enhances alloy strength and hardness by forming fine, uniformly distributed precipitates that hinder dislocation motion, improving yield strength and tensile strength significantly. Solution hardening increases ductility and toughness by dissolving alloying elements into the base metal, creating lattice distortions that resist dislocation movement without compromising material malleability. Both methods optimize mechanical properties but are selected based on the desired balance between strength, hardness, and ductility in alloy design.

Applications of Precipitation Hardened Alloys

Precipitation hardened alloys are widely used in aerospace, automotive, and military applications due to their high strength-to-weight ratio and excellent fatigue resistance. These alloys, such as aluminum 2024 and titanium 6Al-4V, exhibit superior mechanical properties achieved through controlled heat treatment processes that create fine precipitates within the metal matrix. Their ability to maintain strength at elevated temperatures makes them ideal for turbine blades, structural aircraft components, and high-performance engine parts.

Applications of Solution Hardened Alloys

Solution hardened alloys exhibit enhanced strength and corrosion resistance, making them ideal for aerospace components, such as turbine blades and structural airframe parts. Their ability to maintain mechanical properties at elevated temperatures suits automotive engine parts and chemical processing equipment. These alloys also find applications in marine environments, where resistance to stress corrosion cracking is critical.

Process Steps: Precipitation vs Solution Hardening

Precipitation hardening involves heating the alloy to a high temperature to create a homogeneous solid solution, followed by rapid cooling and aging to precipitate fine particles that obstruct dislocation motion. Solution hardening requires dissolving alloying elements into the base metal at elevated temperatures, then quenching to retain a supersaturated solid solution that increases strength by lattice distortion. The aging step in precipitation hardening contrasts with the direct quenching in solution hardening, making their process sequences distinct in controlling microstructure and mechanical properties.

Advantages and Limitations of Each Hardening Method

Precipitation hardening offers significant strength improvements by forming fine, dispersed particles that impede dislocation movement, but it requires precise heat treatment control and may lead to reduced ductility. Solution hardening enhances alloy strength through the distortion of the metal lattice by solute atoms, providing good toughness and ease of processing, though its hardening potential is limited compared to precipitation hardening. Both methods serve distinct applications depending on the desired balance between strength, ductility, and thermal stability in alloy design.

Selecting the Right Hardening Technique for Alloy Performance

Selecting the right hardening technique for alloy performance depends on the desired mechanical properties and service conditions. Precipitation hardening enhances strength through fine particle formation within the metal matrix, ideal for high-temperature applications, while solution hardening improves ductility and toughness by dissolving alloying elements uniformly. Understanding the alloy composition and operating environment ensures optimal hardness, durability, and resistance to deformation.

Precipitation Hardening vs Solution Hardening Infographic

materialdif.com

materialdif.com