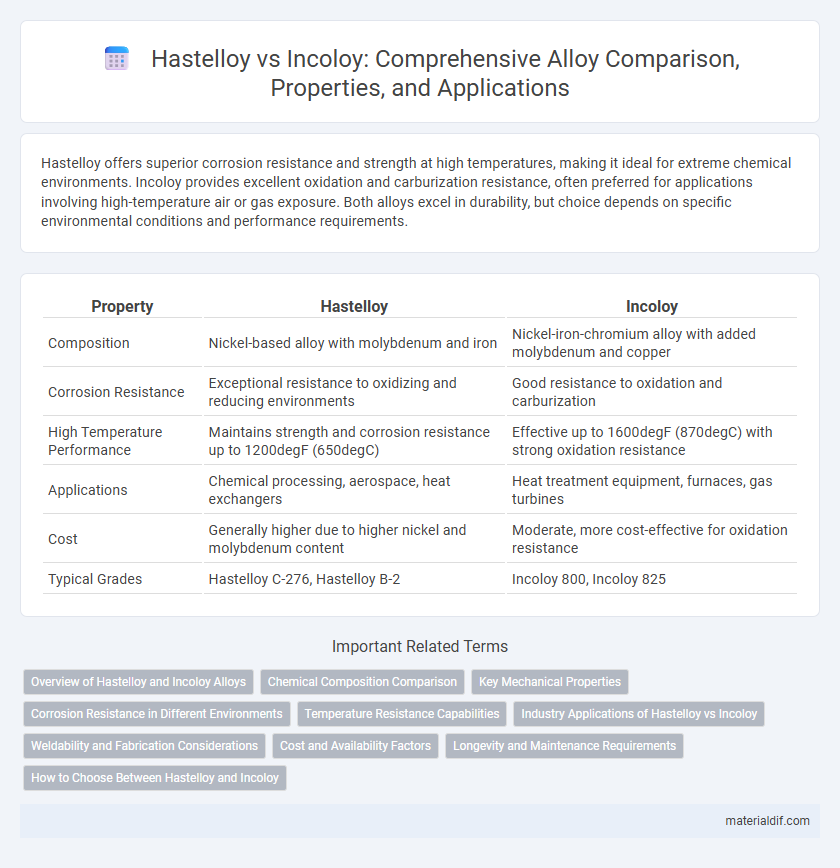

Hastelloy offers superior corrosion resistance and strength at high temperatures, making it ideal for extreme chemical environments. Incoloy provides excellent oxidation and carburization resistance, often preferred for applications involving high-temperature air or gas exposure. Both alloys excel in durability, but choice depends on specific environmental conditions and performance requirements.

Table of Comparison

| Property | Hastelloy | Incoloy |

|---|---|---|

| Composition | Nickel-based alloy with molybdenum and iron | Nickel-iron-chromium alloy with added molybdenum and copper |

| Corrosion Resistance | Exceptional resistance to oxidizing and reducing environments | Good resistance to oxidation and carburization |

| High Temperature Performance | Maintains strength and corrosion resistance up to 1200degF (650degC) | Effective up to 1600degF (870degC) with strong oxidation resistance |

| Applications | Chemical processing, aerospace, heat exchangers | Heat treatment equipment, furnaces, gas turbines |

| Cost | Generally higher due to higher nickel and molybdenum content | Moderate, more cost-effective for oxidation resistance |

| Typical Grades | Hastelloy C-276, Hastelloy B-2 | Incoloy 800, Incoloy 825 |

Overview of Hastelloy and Incoloy Alloys

Hastelloy alloys are nickel-based superalloys known for exceptional corrosion resistance and high-temperature strength, often used in chemical processing and aerospace industries. Incoloy alloys, primarily composed of nickel, iron, and chromium, offer excellent oxidation and corrosion resistance in moderately high temperatures, commonly utilized in heat exchangers and furnace components. Both alloys are engineered for durability in harsh environments, with Hastelloy excelling in highly corrosive conditions and Incoloy providing reliable performance in oxidative or mildly corrosive atmospheres.

Chemical Composition Comparison

Hastelloy primarily consists of nickel, molybdenum, and iron, with molybdenum content typically ranging from 14% to 17%, enhancing its corrosion resistance in aggressive chemical environments. Incoloy features a higher iron content paired with nickel and chromium, with chromium levels around 10% to 30%, which provides excellent oxidation and carburization resistance at elevated temperatures. The distinct chemical compositions of Hastelloy and Incoloy define their suitability for different industrial applications, especially in chemical processing and high-temperature environments.

Key Mechanical Properties

Hastelloy alloys exhibit superior corrosion resistance and high tensile strength, making them ideal for extreme environments, while Incoloy offers excellent oxidation resistance and good creep strength at moderately high temperatures. Hastelloy typically has higher yield strength and better fatigue resistance, supporting durability under cyclic loading conditions. Incoloy's balanced mechanical properties ensure performance stability in chemical processing and heat exchanger applications where thermal expansion and toughness are critical.

Corrosion Resistance in Different Environments

Hastelloy exhibits superior corrosion resistance in highly oxidizing and reducing environments, making it ideal for chemical processing applications involving acids and harsh chemicals. Incoloy offers excellent resistance to oxidation and carburization at elevated temperatures, often used in heat treatment and thermocouple protection. Both alloys perform well in marine environments, but Hastelloy typically outperforms Incoloy in aggressive chloride and pitting corrosion conditions.

Temperature Resistance Capabilities

Hastelloy alloys exhibit exceptional temperature resistance, maintaining structural integrity and corrosion resistance at temperatures up to 2200degF (1204degC), making them ideal for high-temperature chemical processes. Incoloy alloys perform effectively in moderately high temperatures, typically up to 1300degF (704degC), with strong oxidation and carburization resistance. Hastelloy's superior high-temperature strength and stability outperform Incoloy in extreme thermal environments.

Industry Applications of Hastelloy vs Incoloy

Hastelloy outperforms Incoloy in chemical processing industries due to its exceptional resistance to oxidizing and reducing agents, making it ideal for reactors, heat exchangers, and pressure vessels. Incoloy is preferred in aerospace and nuclear applications for its excellent strength and oxidation resistance at elevated temperatures, often used in turbine blades and nuclear reactor components. Both alloys are vital in harsh environments, but Hastelloy's superior corrosion resistance drives its extensive use in aggressive chemical and marine industries.

Weldability and Fabrication Considerations

Hastelloy demonstrates excellent weldability due to its high corrosion resistance and stable microstructure, making it suitable for complex fabrication processes requiring high strength and stress tolerance. Incoloy also offers good weldability but requires precise heat control to avoid hot cracking and maintain its mechanical properties during fabrication. Both alloys demand specific welding techniques such as TIG or MIG welding, with post-weld heat treatment often necessary to preserve structural integrity and corrosion resistance.

Cost and Availability Factors

Hastelloy offers superior corrosion resistance but comes at a higher cost due to its nickel and molybdenum content, which can impact budget-sensitive projects. Incoloy is generally more affordable with more readily available supplies, making it a preferred choice for applications requiring good corrosion resistance at lower costs. Availability fluctuations for Hastelloy often result from its complex manufacturing process and demand in specialized industries.

Longevity and Maintenance Requirements

Hastelloy exhibits superior longevity compared to Incoloy due to its exceptional resistance to oxidation and corrosion in high-temperature environments, often extending operational life by several years in demanding chemical processes. Incoloy requires more frequent maintenance because its chromium-nickel-iron composition is less resistant to acidic and oxidative conditions, leading to faster degradation and potential structural weakening. Selecting Hastelloy reduces downtime and maintenance costs, making it the preferred alloy for applications requiring durable, long-term performance.

How to Choose Between Hastelloy and Incoloy

Selecting between Hastelloy and Incoloy depends on the corrosion resistance and temperature tolerance required for the application. Hastelloy excels in highly corrosive environments with strong acids, offering superior strength at elevated temperatures up to 2000degF (1093degC). Incoloy provides excellent oxidation resistance and stability in moderate acidic or high-temperature environments, performing well up to 2100degF (1149degC), making it ideal for heat exchangers and furnace components.

Hastelloy vs Incoloy Infographic

materialdif.com

materialdif.com