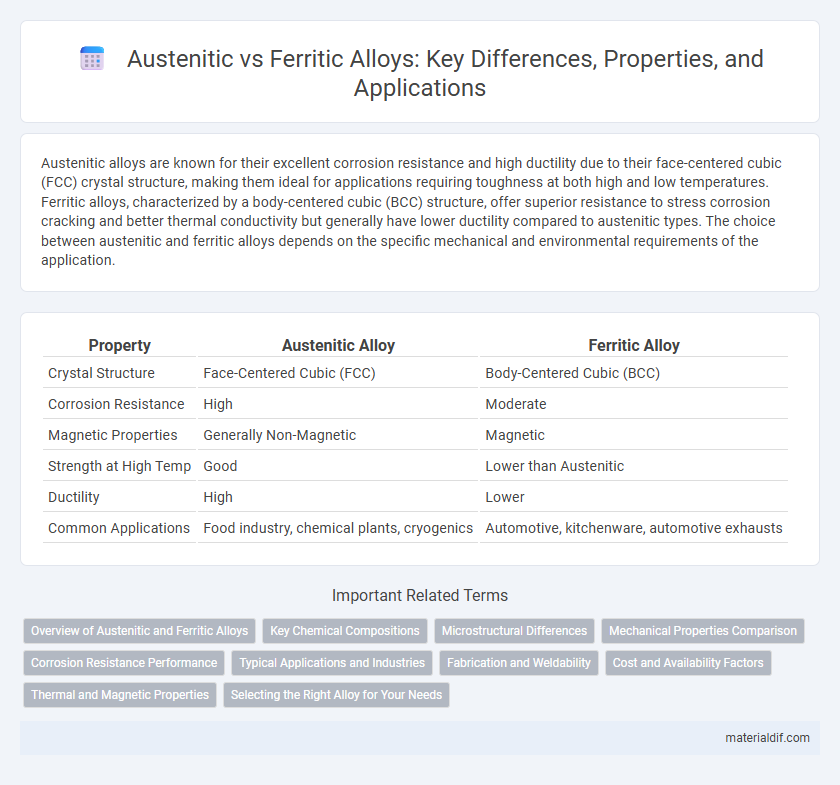

Austenitic alloys are known for their excellent corrosion resistance and high ductility due to their face-centered cubic (FCC) crystal structure, making them ideal for applications requiring toughness at both high and low temperatures. Ferritic alloys, characterized by a body-centered cubic (BCC) structure, offer superior resistance to stress corrosion cracking and better thermal conductivity but generally have lower ductility compared to austenitic types. The choice between austenitic and ferritic alloys depends on the specific mechanical and environmental requirements of the application.

Table of Comparison

| Property | Austenitic Alloy | Ferritic Alloy |

|---|---|---|

| Crystal Structure | Face-Centered Cubic (FCC) | Body-Centered Cubic (BCC) |

| Corrosion Resistance | High | Moderate |

| Magnetic Properties | Generally Non-Magnetic | Magnetic |

| Strength at High Temp | Good | Lower than Austenitic |

| Ductility | High | Lower |

| Common Applications | Food industry, chemical plants, cryogenics | Automotive, kitchenware, automotive exhausts |

Overview of Austenitic and Ferritic Alloys

Austenitic alloys primarily consist of a face-centered cubic (FCC) structure with high chromium and nickel content, offering excellent corrosion resistance and superior toughness at low temperatures. Ferritic alloys feature a body-centered cubic (BCC) structure with high chromium but low nickel, providing good resistance to oxidation and stress corrosion cracking, especially in high-temperature environments. Both types are widely used in stainless steel production, with austenitic alloys favored for cryogenic and marine applications, while ferritic alloys excel in automotive and industrial furnace components.

Key Chemical Compositions

Austenitic alloys primarily contain high levels of chromium (16-26%) and nickel (6-22%), with low carbon content, enhancing corrosion resistance and toughness. Ferritic alloys feature chromium levels ranging from 10.5% to 30%, minimal nickel, and low carbon, offering superior stress corrosion cracking resistance and magnetic properties. The key chemical difference lies in the nickel content, which stabilizes the austenitic phase, while ferritic steels rely on chromium for oxidation and corrosion resistance.

Microstructural Differences

Austenitic alloys exhibit a face-centered cubic (FCC) crystal structure, which provides excellent ductility and corrosion resistance due to the uniform distribution of alloying elements like nickel and chromium. Ferritic alloys possess a body-centered cubic (BCC) microstructure characterized by higher magnetic permeability and better resistance to stress corrosion cracking but lower toughness compared to austenitic grades. The microstructural differences significantly influence mechanical properties, corrosion behavior, and magnetic responses in stainless steel applications.

Mechanical Properties Comparison

Austenitic alloys exhibit superior ductility and toughness with higher tensile strength and excellent corrosion resistance, making them ideal for extreme temperature applications. Ferritic alloys offer better resistance to stress corrosion cracking and demonstrate moderate strength with higher thermal conductivity and magnetic properties. Mechanical properties of austenitic stainless steels typically include tensile strength around 515-775 MPa, while ferritic stainless steels range from 400-700 MPa.

Corrosion Resistance Performance

Austenitic alloys exhibit superior corrosion resistance due to their high chromium and nickel content, which forms a stable oxide layer protecting against oxidizing environments. Ferritic alloys, characterized by lower nickel levels and higher chromium content, offer good resistance to stress corrosion cracking but are more susceptible to pitting and crevice corrosion in chloride-rich environments. The choice between austenitic and ferritic alloys depends on the specific corrosive conditions and required performance in applications such as chemical processing or marine environments.

Typical Applications and Industries

Austenitic alloys, known for their excellent corrosion resistance and high ductility, are widely used in chemical processing, food and beverage equipment, and medical devices. Ferritic alloys, featuring superior stress corrosion cracking resistance and magnetic properties, are commonly applied in automotive exhaust systems, industrial cookware, and architectural components. Both alloy types serve critical roles across heat exchangers, power plants, and petrochemical industries, depending on specific mechanical and environmental requirements.

Fabrication and Weldability

Austenitic alloys exhibit excellent weldability due to their high ductility and ability to withstand thermal distortion, making them ideal for complex fabrications requiring extensive welding. Ferritic alloys, while offering good corrosion resistance, present challenges in welding processes because of their higher susceptibility to grain growth and brittleness at elevated temperatures. Fabrication of ferritic alloys often demands precise control of heat input and post-weld heat treatment to maintain structural integrity and prevent cracking.

Cost and Availability Factors

Austenitic alloys generally have higher production costs due to their increased nickel content, which also impacts their availability as nickel prices fluctuate globally. Ferritic alloys, with lower nickel levels, tend to be more cost-effective and widely available, making them preferable for budget-sensitive applications. The choice between the two often hinges on balancing upfront alloy costs against performance requirements and market availability of key raw materials.

Thermal and Magnetic Properties

Austenitic alloys exhibit superior thermal stability with high resistance to oxidation and corrosion at elevated temperatures, making them ideal for high-temperature applications. Ferritic alloys possess lower thermal expansion and better thermal conductivity, enhancing heat dissipation but are generally limited to lower temperature uses. Magnetically, austenitic alloys are typically non-magnetic due to their face-centered cubic (FCC) structure, while ferritic alloys are magnetic, attributed to their body-centered cubic (BCC) crystal lattice.

Selecting the Right Alloy for Your Needs

Austenitic alloys, such as 300 series stainless steels, offer superior corrosion resistance and excellent toughness, making them ideal for highly corrosive environments and cryogenic applications. Ferritic alloys, typically containing higher chromium content but lower nickel, provide good stress corrosion cracking resistance and are more cost-effective, suitable for automotive exhaust systems and industrial equipment. Selecting the right alloy depends on the specific environmental conditions, mechanical requirements, and budget constraints of the application.

Austenitic vs Ferritic Infographic

materialdif.com

materialdif.com