Precipitation-hardened alloys achieve high strength through the formation of finely dispersed particles that hinder dislocation movement, enhancing mechanical properties after aging treatment. Solution-treated alloys rely on dissolving alloying elements into a solid solution and rapidly quenching to produce a supersaturated matrix, allowing for improved ductility and toughness before any precipitation occurs. The choice between these treatments depends on whether peak strength or a balance of strength and toughness is required for the application.

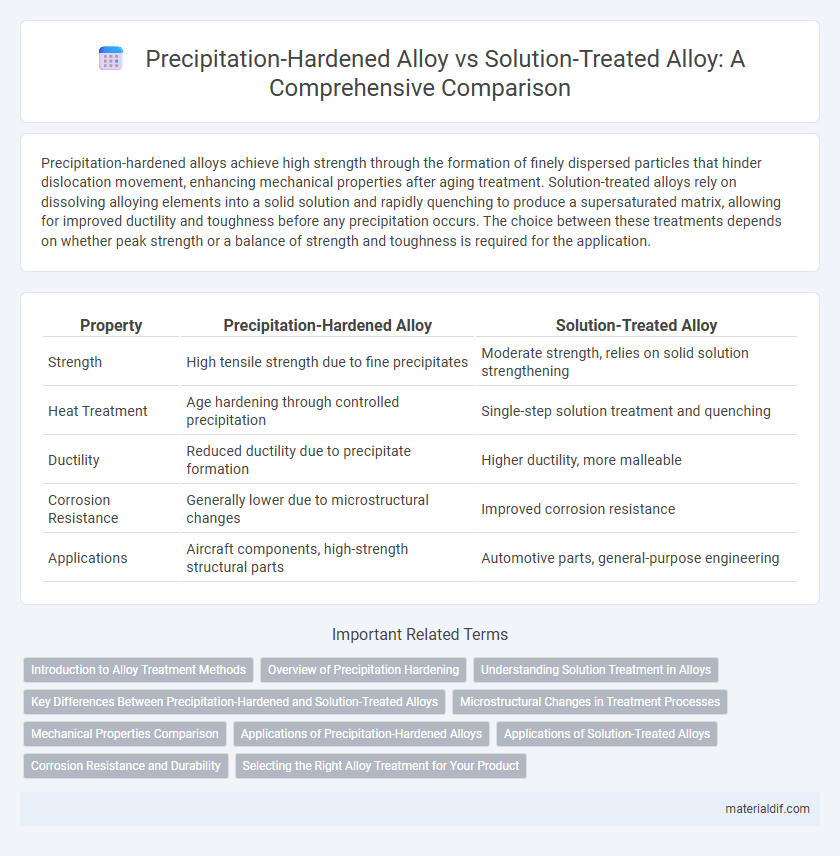

Table of Comparison

| Property | Precipitation-Hardened Alloy | Solution-Treated Alloy |

|---|---|---|

| Strength | High tensile strength due to fine precipitates | Moderate strength, relies on solid solution strengthening |

| Heat Treatment | Age hardening through controlled precipitation | Single-step solution treatment and quenching |

| Ductility | Reduced ductility due to precipitate formation | Higher ductility, more malleable |

| Corrosion Resistance | Generally lower due to microstructural changes | Improved corrosion resistance |

| Applications | Aircraft components, high-strength structural parts | Automotive parts, general-purpose engineering |

Introduction to Alloy Treatment Methods

Precipitation-hardened alloys undergo a heat treatment process that forms fine particles within the metal matrix, significantly enhancing strength and hardness by impeding dislocation movement. Solution-treated alloys are heated to dissolve solute atoms into a single-phase solid solution, followed by rapid cooling to retain the solute in a supersaturated state, improving ductility and corrosion resistance. These distinct alloy treatment methods optimize mechanical properties for aerospace, automotive, and structural applications.

Overview of Precipitation Hardening

Precipitation hardening, also known as age hardening, enhances alloy strength by forming fine, dispersed particles within the metal matrix through controlled heat treatment. This process involves solution treating the alloy to create a uniform solid solution, followed by quenching and aging to precipitate strengthening phases. Precipitation-hardened alloys exhibit superior mechanical properties and corrosion resistance compared to solution-treated alloys due to these finely distributed precipitates.

Understanding Solution Treatment in Alloys

Solution treatment in alloys involves heating the material to a temperature where alloying elements dissolve into a solid solution, creating a uniform single-phase microstructure. This process enhances mechanical properties by dissolving precipitates that would otherwise cause stress concentrations and weaknesses. Precise control of temperature and cooling rates during solution treatment is critical to achieving optimal hardness and strength in precipitation-hardened alloys.

Key Differences Between Precipitation-Hardened and Solution-Treated Alloys

Precipitation-hardened alloys gain strength through the formation of fine particles that impede dislocation movement during aging, whereas solution-treated alloys rely on a homogeneous solid solution achieved by quenching from a high temperature. The key difference lies in microstructural development: precipitation-hardening produces dispersed secondary phases, while solution treatment stabilizes a single-phase matrix. As a result, precipitation-hardened alloys exhibit higher strength and improved mechanical properties compared to solution-treated ones.

Microstructural Changes in Treatment Processes

Precipitation-hardened alloys undergo a controlled aging process that promotes the formation of fine, uniformly dispersed precipitates within the metal matrix, significantly enhancing strength and hardness. Solution-treated alloys experience heating to dissolve alloying elements into a solid solution, followed by rapid quenching to retain a supersaturated solid solution and improve ductility. The microstructural changes in precipitation hardening focus on nucleation and growth of precipitates, whereas solution treatment emphasizes homogenization and retention of alloying elements in solution.

Mechanical Properties Comparison

Precipitation-hardened alloys exhibit superior tensile strength and hardness compared to solution-treated alloys due to the formation of fine, uniformly dispersed precipitates that hinder dislocation motion. Solution-treated alloys generally offer better ductility and toughness as the microstructure remains more homogeneous without the presence of strengthening precipitates. The mechanical performance trade-off between these treatments is critical in aerospace and automotive applications, where strength-to-weight ratio and fatigue resistance are prioritized.

Applications of Precipitation-Hardened Alloys

Precipitation-hardened alloys are widely used in aerospace, automotive, and marine industries due to their superior strength and corrosion resistance at elevated temperatures. These alloys enable the manufacture of critical components such as turbine blades, aircraft structural parts, and high-performance engine components. Their enhanced mechanical properties make them ideal for applications requiring high fatigue resistance and dimensional stability under stress.

Applications of Solution-Treated Alloys

Solution-treated alloys are widely used in aerospace and automotive industries due to their enhanced corrosion resistance and improved toughness. Their application in structural components, such as aircraft frames and engine parts, relies on the uniform microstructure achieved through solution treatment. This heat treatment process optimizes mechanical properties, making them ideal for high-stress environments requiring durability and precision.

Corrosion Resistance and Durability

Precipitation-hardened alloys exhibit superior corrosion resistance due to the formation of fine, uniformly distributed precipitates that enhance the alloy's protective oxide layer, reducing susceptibility to localized corrosion. Solution-treated alloys display increased durability by homogenizing the microstructure, eliminating segregation, and improving mechanical properties, although they may have lower corrosion resistance in aggressive environments. Comparing both, precipitation-hardened alloys offer a balanced combination of enhanced corrosion resistance and strength, making them ideal for applications requiring long-term durability under corrosive conditions.

Selecting the Right Alloy Treatment for Your Product

Precipitation-hardened alloys offer superior strength by forming fine particles that obstruct dislocation movement, making them ideal for high-stress applications. Solution-treated alloys provide enhanced ductility and corrosion resistance by dissolving alloying elements into a solid solution, suitable for components requiring formability and toughness. Selecting the right alloy treatment depends on balancing mechanical strength with corrosion resistance tailored to the specific performance demands of your product.

Precipitation-hardened alloy vs Solution-treated alloy Infographic

materialdif.com

materialdif.com