Alloy 304 offers excellent corrosion resistance and is widely used for general-purpose applications, while Alloy 316 provides enhanced resistance to chlorides and harsh environments, making it ideal for marine and chemical industries. The higher molybdenum content in Alloy 316 improves pitting and crevice corrosion resistance compared to Alloy 304. Selecting between Alloy 304 and Alloy 316 depends on the specific environmental conditions and durability requirements of your application.

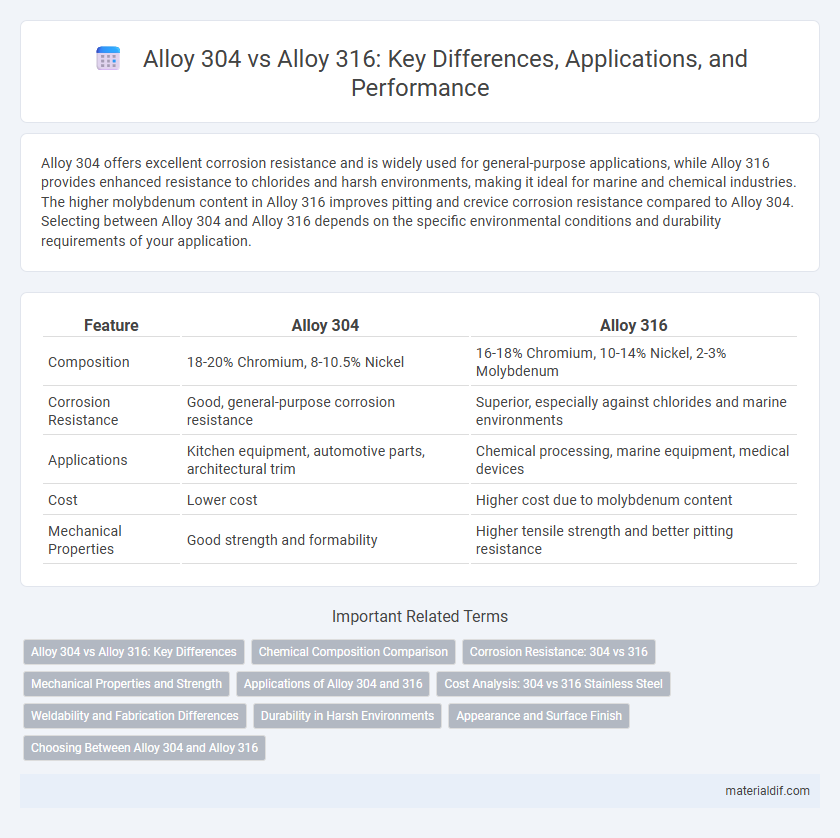

Table of Comparison

| Feature | Alloy 304 | Alloy 316 |

|---|---|---|

| Composition | 18-20% Chromium, 8-10.5% Nickel | 16-18% Chromium, 10-14% Nickel, 2-3% Molybdenum |

| Corrosion Resistance | Good, general-purpose corrosion resistance | Superior, especially against chlorides and marine environments |

| Applications | Kitchen equipment, automotive parts, architectural trim | Chemical processing, marine equipment, medical devices |

| Cost | Lower cost | Higher cost due to molybdenum content |

| Mechanical Properties | Good strength and formability | Higher tensile strength and better pitting resistance |

Alloy 304 vs Alloy 316: Key Differences

Alloy 304 and Alloy 316 differ primarily in their chemical composition, with Alloy 316 containing molybdenum that enhances corrosion resistance, especially against chlorides and marine environments. Alloy 304 offers excellent general corrosion resistance and formability but is less resistant to pitting and crevice corrosion compared to Alloy 316. The choice between Alloy 304 and Alloy 316 depends on the specific environmental demands and application requirements, such as exposure to harsh chemicals or saltwater.

Chemical Composition Comparison

Alloy 304 primarily consists of 18-20% chromium and 8-10.5% nickel, while Alloy 316 contains 16-18% chromium, 10-14% nickel, and 2-3% molybdenum, enhancing corrosion resistance. The presence of molybdenum in Alloy 316 significantly improves resistance to chlorides and marine environments compared to Alloy 304. Both alloys maintain low carbon content, typically under 0.08%, to reduce carbide precipitation and maintain corrosion resistance.

Corrosion Resistance: 304 vs 316

Alloy 304 offers good corrosion resistance in mild environments, while Alloy 316 excels in highly corrosive conditions due to its molybdenum content. The presence of molybdenum in Alloy 316 enhances resistance to chlorides and industrial chemicals, making it ideal for marine and chemical applications. Compared to Alloy 304, Alloy 316 provides superior protection against pitting and crevice corrosion.

Mechanical Properties and Strength

Alloy 304 exhibits a tensile strength of approximately 505 MPa and good ductility, making it suitable for general-purpose applications. In comparison, Alloy 316 offers higher corrosion resistance with a tensile strength around 579 MPa, attributed to the addition of molybdenum which enhances its mechanical strength. Both alloys maintain excellent toughness at low temperatures, but Alloy 316's superior strength makes it preferable for more demanding environments.

Applications of Alloy 304 and 316

Alloy 304 finds extensive use in kitchen equipment, food processing, and architectural applications due to its excellent formability and corrosion resistance in mild environments. Alloy 316 is preferred in marine, chemical, and pharmaceutical industries where higher resistance to chloride corrosion and pitting is essential. Both alloys serve critical roles in environments requiring stainless steel durability, with Alloy 316 being the top choice for harsher, more corrosive settings.

Cost Analysis: 304 vs 316 Stainless Steel

Alloy 304 stainless steel generally costs less than Alloy 316 due to its lower nickel and molybdenum content, making it a more economical choice for applications not exposed to harsh environments. Alloy 316 offers superior corrosion resistance, particularly against chlorides and marine environments, which justifies its higher price in industries requiring durability and longevity. When deciding between 304 and 316 stainless steel, cost analysis must include maintenance, lifespan, and environmental factors to ensure the best value over the material's service life.

Weldability and Fabrication Differences

Alloy 304 exhibits superior weldability due to its lower carbon content, reducing the risk of carbide precipitation and ensuring strong, crack-free joints during fabrication. Alloy 316, containing molybdenum, provides enhanced corrosion resistance but requires more precise welding techniques to prevent sensitization and maintain mechanical integrity. Fabrication differences also include Alloy 316's increased tendency for work hardening, necessitating controlled cutting and forming processes compared to the more versatile Alloy 304.

Durability in Harsh Environments

Alloy 316 offers superior corrosion resistance and durability in harsh environments compared to Alloy 304, thanks to its molybdenum content that enhances protection against chlorides and acidic conditions. This makes Alloy 316 the preferred choice for marine, chemical processing, and saltwater applications where prolonged exposure to aggressive elements occurs. Although Alloy 304 is cost-effective and resistant to oxidation, it is less durable in highly corrosive settings, limiting its usability under severe environmental stress.

Appearance and Surface Finish

Alloy 304 exhibits a bright, smooth surface with a slightly duller finish compared to Alloy 316, which maintains a more lustrous and polished appearance due to its higher nickel and molybdenum content. The surface finish of Alloy 316 resists tarnishing and corrosion more effectively, preserving its glossy look in harsh environments. Both alloys can be polished to a mirror finish, but Alloy 316 generally offers superior surface durability and aesthetic longevity.

Choosing Between Alloy 304 and Alloy 316

Alloy 304 offers excellent corrosion resistance and cost-effectiveness, making it suitable for general-purpose applications in environments without harsh chemicals or seawater exposure. Alloy 316 contains molybdenum, enhancing its resistance to chloride corrosion, making it ideal for marine, chemical processing, and saline environments. Selecting between Alloy 304 and Alloy 316 depends on the specific exposure to corrosive agents, with Alloy 316 preferred for harsher conditions requiring superior durability.

Alloy 304 vs Alloy 316 Infographic

materialdif.com

materialdif.com