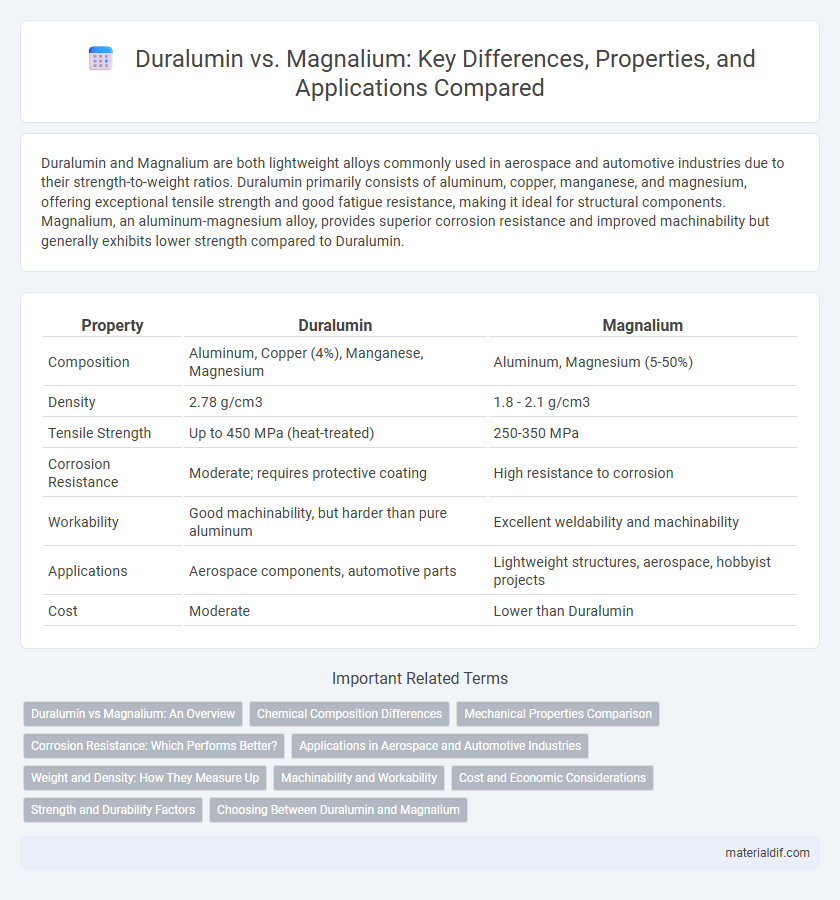

Duralumin and Magnalium are both lightweight alloys commonly used in aerospace and automotive industries due to their strength-to-weight ratios. Duralumin primarily consists of aluminum, copper, manganese, and magnesium, offering exceptional tensile strength and good fatigue resistance, making it ideal for structural components. Magnalium, an aluminum-magnesium alloy, provides superior corrosion resistance and improved machinability but generally exhibits lower strength compared to Duralumin.

Table of Comparison

| Property | Duralumin | Magnalium |

|---|---|---|

| Composition | Aluminum, Copper (4%), Manganese, Magnesium | Aluminum, Magnesium (5-50%) |

| Density | 2.78 g/cm3 | 1.8 - 2.1 g/cm3 |

| Tensile Strength | Up to 450 MPa (heat-treated) | 250-350 MPa |

| Corrosion Resistance | Moderate; requires protective coating | High resistance to corrosion |

| Workability | Good machinability, but harder than pure aluminum | Excellent weldability and machinability |

| Applications | Aerospace components, automotive parts | Lightweight structures, aerospace, hobbyist projects |

| Cost | Moderate | Lower than Duralumin |

Duralumin vs Magnalium: An Overview

Duralumin is an aluminum alloy primarily composed of aluminum, copper, manganese, and magnesium, known for its high strength and lightweight properties, making it ideal for aerospace applications. Magnalium, an aluminum-magnesium alloy, offers enhanced corrosion resistance and improved machinability compared to Duralumin but has slightly lower tensile strength. Selecting between Duralumin and Magnalium depends on the balance required between mechanical strength, corrosion resistance, and manufacturing ease in engineering projects.

Chemical Composition Differences

Duralumin primarily consists of aluminum alloyed with around 4% copper, 0.5-1% magnesium, and small amounts of manganese and iron, enhancing its strength and hardness. Magnalium, in contrast, is an aluminum alloy with a higher magnesium content, typically between 5% and 50%, which improves corrosion resistance and reduces weight. The key chemical composition difference lies in Duralumin's copper content that boosts tensile strength, whereas Magnalium's elevated magnesium percentage optimizes lightness and oxidation resistance.

Mechanical Properties Comparison

Duralumin exhibits higher tensile strength and superior fatigue resistance compared to Magnalium, making it ideal for aerospace and structural applications. Magnalium offers enhanced corrosion resistance and lower density, which benefits lightweight components with moderate mechanical demands. Both alloys balance strength and weight differently, with Duralumin favoring mechanical durability and Magnalium prioritizing weight reduction.

Corrosion Resistance: Which Performs Better?

Duralumin, an aluminum-copper alloy, exhibits moderate corrosion resistance enhanced by its copper content but requires protective coatings to prevent oxidation. Magnalium, composed primarily of aluminum and magnesium, offers superior corrosion resistance due to magnesium's protective oxide layer, making it more suitable for marine and humid environments. In terms of corrosion performance, Magnalium generally outperforms Duralumin, especially in applications exposed to moisture and corrosive atmospheres.

Applications in Aerospace and Automotive Industries

Duralumin, an aluminum-copper alloy, is favored in aerospace for its high strength-to-weight ratio and excellent fatigue resistance, making it ideal for structural aircraft components. Magnalium, an aluminum-magnesium alloy with improved corrosion resistance and lighter weight, is commonly used in automotive parts and aerospace components that require enhanced durability and reduced mass. Both alloys contribute significantly to weight reduction and performance optimization in the aerospace and automotive industries.

Weight and Density: How They Measure Up

Duralumin, an aluminum-copper alloy, typically has a density of around 2.8 g/cm3, making it lightweight yet strong for aerospace applications. Magnalium, an aluminum-magnesium alloy, offers a lower density near 2.6 g/cm3, providing enhanced weight savings without sacrificing structural integrity. This difference in density positions Magnalium as the preferred choice for components where minimizing weight is critical, while Duralumin remains favored for its superior strength-to-weight ratio.

Machinability and Workability

Duralumin, an aluminum-copper alloy, offers excellent machinability and is highly favored for precision machining due to its hardness and strength. Magnalium, an aluminum-magnesium alloy, provides superior workability with improved malleability and corrosion resistance, making it easier to shape and form. While Duralumin excels in machining applications requiring durability, Magnalium is preferred for projects demanding ease of fabrication and lightweight properties.

Cost and Economic Considerations

Duralumin, primarily composed of aluminum, copper, manganese, and magnesium, offers a cost-effective solution widely used in aerospace due to its high strength-to-weight ratio and excellent fatigue resistance. Magnalium, an aluminum-magnesium alloy, generally incurs higher production costs but provides enhanced corrosion resistance and improved machinability, making it economical in applications requiring less maintenance and longer lifespan. When choosing between Duralumin and Magnalium, cost analysis must consider not only initial material expenses but also lifecycle savings related to performance and durability.

Strength and Durability Factors

Duralumin, an aluminum-copper alloy, offers superior strength due to copper content, making it highly durable under mechanical stress and commonly used in aerospace applications. Magnalium, an aluminum-magnesium alloy, provides enhanced corrosion resistance and better impact toughness but generally has lower tensile strength compared to Duralumin. Strength factors favor Duralumin for load-bearing uses, while Durability factors such as oxidation resistance lean towards Magnalium in harsh environmental conditions.

Choosing Between Duralumin and Magnalium

Choosing between duralumin and magnalium depends on the specific application requirements such as strength-to-weight ratio, corrosion resistance, and machinability. Duralumin, an aluminum-copper alloy, offers high tensile strength and excellent fatigue resistance, making it ideal for aerospace and automotive components. Magnalium, an aluminum-magnesium alloy, provides superior corrosion resistance and lighter weight, preferred in marine environments and lightweight structural parts.

Duralumin vs Magnalium Infographic

materialdif.com

materialdif.com