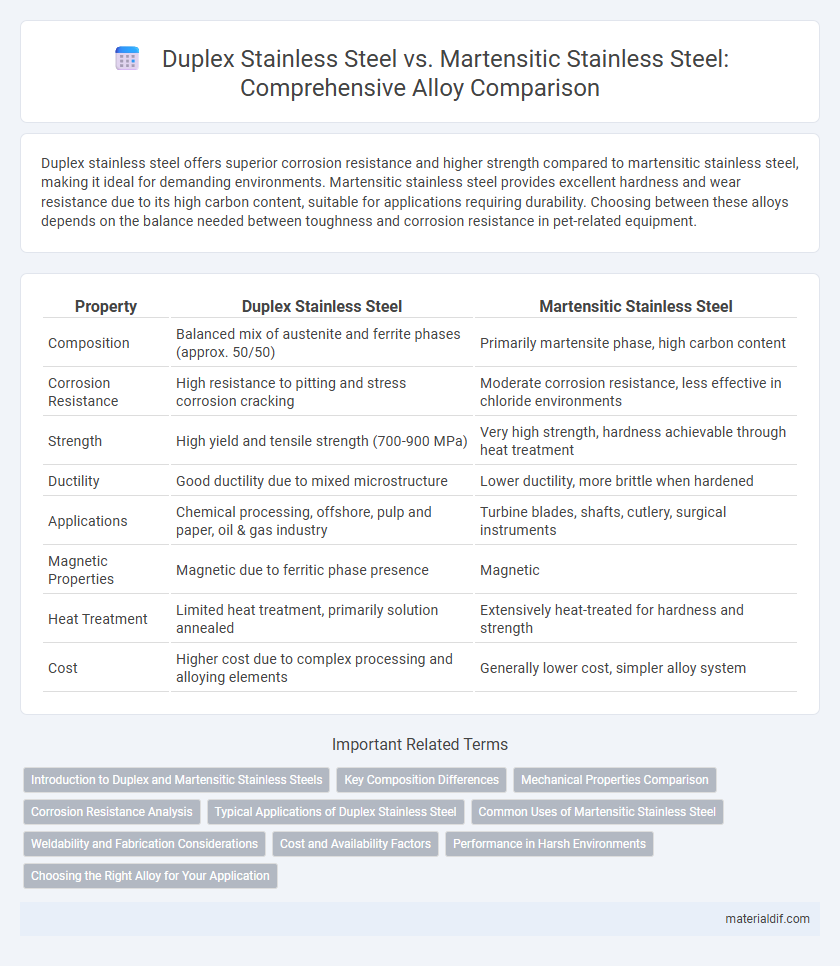

Duplex stainless steel offers superior corrosion resistance and higher strength compared to martensitic stainless steel, making it ideal for demanding environments. Martensitic stainless steel provides excellent hardness and wear resistance due to its high carbon content, suitable for applications requiring durability. Choosing between these alloys depends on the balance needed between toughness and corrosion resistance in pet-related equipment.

Table of Comparison

| Property | Duplex Stainless Steel | Martensitic Stainless Steel |

|---|---|---|

| Composition | Balanced mix of austenite and ferrite phases (approx. 50/50) | Primarily martensite phase, high carbon content |

| Corrosion Resistance | High resistance to pitting and stress corrosion cracking | Moderate corrosion resistance, less effective in chloride environments |

| Strength | High yield and tensile strength (700-900 MPa) | Very high strength, hardness achievable through heat treatment |

| Ductility | Good ductility due to mixed microstructure | Lower ductility, more brittle when hardened |

| Applications | Chemical processing, offshore, pulp and paper, oil & gas industry | Turbine blades, shafts, cutlery, surgical instruments |

| Magnetic Properties | Magnetic due to ferritic phase presence | Magnetic |

| Heat Treatment | Limited heat treatment, primarily solution annealed | Extensively heat-treated for hardness and strength |

| Cost | Higher cost due to complex processing and alloying elements | Generally lower cost, simpler alloy system |

Introduction to Duplex and Martensitic Stainless Steels

Duplex stainless steel combines austenitic and ferritic microstructures, offering enhanced corrosion resistance and high strength, making it ideal for chemical processing and marine applications. Martensitic stainless steel features a martensitic microstructure known for high hardness, excellent wear resistance, and moderate corrosion resistance, commonly used in cutlery and aerospace components. Both alloys deliver distinct mechanical and corrosion-resistant properties tailored for specific industrial environments.

Key Composition Differences

Duplex stainless steel contains a balanced microstructure of approximately 50% austenite and 50% ferrite, with higher chromium (20-28%), molybdenum (1.5-4%), and nitrogen content, enhancing corrosion resistance and strength. Martensitic stainless steel primarily consists of austenite that transforms to martensite upon cooling, with lower chromium (11-18%) and carbon content typically ranging from 0.1% to 1.2%, focusing on hardness and wear resistance. The significant difference lies in the duplex's dual-phase structure and alloying elements that optimize corrosion resistance, whereas martensitic grades emphasize toughness and hardness through carbon and heat treatment.

Mechanical Properties Comparison

Duplex stainless steel exhibits superior mechanical properties compared to martensitic stainless steel, with higher tensile strength typically ranging from 620 to 880 MPa and enhanced yield strength around 450 to 750 MPa. Its balanced microstructure provides excellent toughness and improved resistance to stress corrosion cracking, outperforming martensitic grades that offer tensile strengths up to 1,200 MPa but with reduced ductility and toughness. Duplex stainless steel also demonstrates better fatigue strength and impact resistance, making it suitable for demanding applications requiring a combination of strength and corrosion resistance.

Corrosion Resistance Analysis

Duplex stainless steel demonstrates superior corrosion resistance compared to martensitic stainless steel due to its balanced microstructure of austenite and ferrite phases, which enhances resistance to pitting and stress corrosion cracking. Martensitic stainless steel, while offering higher hardness and strength, is more susceptible to localized corrosion in chloride-rich environments. The combination of duplex stainless steel's higher chromium, molybdenum, and nitrogen content contributes significantly to its improved performance in aggressive corrosive conditions.

Typical Applications of Duplex Stainless Steel

Duplex stainless steel is widely used in chemical processing, oil and gas industries, and marine environments due to its exceptional corrosion resistance and high strength. Typical applications include heat exchangers, pressure vessels, and pipelines where chloride-induced stress corrosion cracking is a concern. Its balanced microstructure provides superior durability in aggressive environments compared to martensitic stainless steel, which is mainly applied in cutlery, valves, and fasteners requiring moderate corrosion resistance and high hardness.

Common Uses of Martensitic Stainless Steel

Martensitic stainless steel is commonly used in applications requiring high strength and moderate corrosion resistance, such as cutting tools, surgical instruments, and valve components. Its ability to be heat treated for enhanced hardness makes it ideal for blades, pump shafts, and turbine parts. This contrasts with duplex stainless steel, which is favored for its superior corrosion resistance in chemical processing and marine environments.

Weldability and Fabrication Considerations

Duplex stainless steel offers superior weldability due to its balanced microstructure that minimizes weld decay and cracking, allowing for higher heat input and faster cooling rates compared to martensitic stainless steel. Martensitic stainless steel requires careful control of heat input and preheating to prevent hardness and brittleness in welds, which complicates fabrication processes. The dual-phase nature of duplex stainless steel ensures better corrosion resistance in weld zones, making it more suitable for demanding fabrication applications.

Cost and Availability Factors

Duplex stainless steel generally costs more than martensitic stainless steel due to its complex microstructure and higher alloying elements like nickel and molybdenum, which enhance corrosion resistance and strength. Martensitic stainless steel is widely available and more economical, making it suitable for applications requiring moderate corrosion resistance and high hardness. Cost efficiency and supply stability favor martensitic grades in markets with budget constraints, while duplex alloys dominate where performance justifies higher expenses.

Performance in Harsh Environments

Duplex stainless steel offers superior corrosion resistance and strength in harsh environments due to its balanced austenitic and ferritic microstructure, making it ideal for chloride-rich and high-stress applications. Martensitic stainless steel, while possessing high hardness and wear resistance, is more prone to stress corrosion cracking and less effective against pitting in aggressive conditions. Consequently, duplex stainless steel outperforms martensitic grades in marine, chemical, and petrochemical industries where durability against corrosion and mechanical stress is critical.

Choosing the Right Alloy for Your Application

Duplex stainless steel offers superior corrosion resistance and higher strength, making it ideal for chemical processing and marine applications where durability and longevity are critical. Martensitic stainless steel provides excellent hardness and wear resistance, suitable for applications requiring strong mechanical properties such as turbine blades and cutlery. Selecting the right alloy depends on balancing corrosion resistance, mechanical strength, and application-specific requirements to optimize performance and cost-efficiency.

Duplex stainless steel vs Martensitic stainless steel Infographic

materialdif.com

materialdif.com