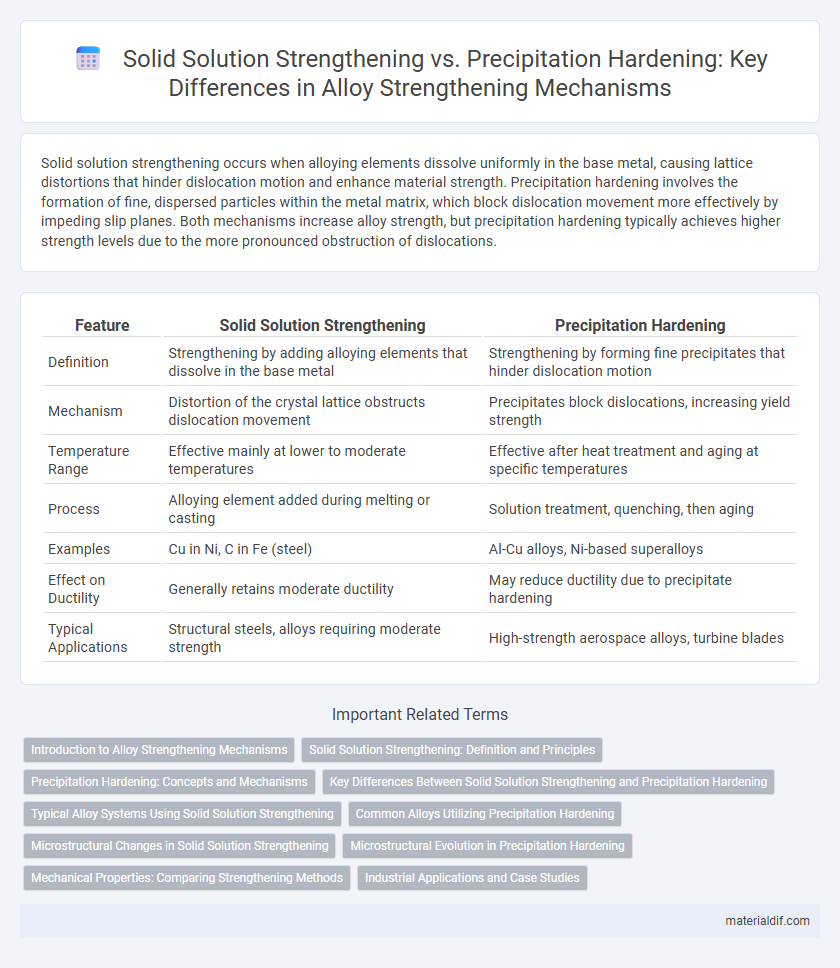

Solid solution strengthening occurs when alloying elements dissolve uniformly in the base metal, causing lattice distortions that hinder dislocation motion and enhance material strength. Precipitation hardening involves the formation of fine, dispersed particles within the metal matrix, which block dislocation movement more effectively by impeding slip planes. Both mechanisms increase alloy strength, but precipitation hardening typically achieves higher strength levels due to the more pronounced obstruction of dislocations.

Table of Comparison

| Feature | Solid Solution Strengthening | Precipitation Hardening |

|---|---|---|

| Definition | Strengthening by adding alloying elements that dissolve in the base metal | Strengthening by forming fine precipitates that hinder dislocation motion |

| Mechanism | Distortion of the crystal lattice obstructs dislocation movement | Precipitates block dislocations, increasing yield strength |

| Temperature Range | Effective mainly at lower to moderate temperatures | Effective after heat treatment and aging at specific temperatures |

| Process | Alloying element added during melting or casting | Solution treatment, quenching, then aging |

| Examples | Cu in Ni, C in Fe (steel) | Al-Cu alloys, Ni-based superalloys |

| Effect on Ductility | Generally retains moderate ductility | May reduce ductility due to precipitate hardening |

| Typical Applications | Structural steels, alloys requiring moderate strength | High-strength aerospace alloys, turbine blades |

Introduction to Alloy Strengthening Mechanisms

Solid solution strengthening enhances alloy strength by dissolving impurity atoms into the metal matrix, creating lattice distortions that impede dislocation motion. Precipitation hardening improves strength through the formation of fine, dispersed secondary phase particles that obstruct dislocation movement. Both mechanisms optimize mechanical properties by altering the microstructure to resist deformation at the atomic level.

Solid Solution Strengthening: Definition and Principles

Solid solution strengthening enhances alloy strength by dissolving solute atoms into the solvent metal's crystal lattice, creating lattice distortions that impede dislocation motion. This mechanism relies on atomic size differences and elastic strain fields to increase the yield strength without forming a separate phase. It improves mechanical properties while maintaining the alloy's ductility and corrosion resistance.

Precipitation Hardening: Concepts and Mechanisms

Precipitation hardening, also known as age hardening, enhances alloy strength by forming fine, dispersed precipitates within the metal matrix that impede dislocation motion. This phase transformation involves solution treatment, quenching, and aging, which promotes nucleation and growth of coherent or semi-coherent precipitates such as CuAl2 in aluminum alloys. The effectiveness of precipitation hardening relies on controlling precipitate size, distribution, and volume fraction to optimize yield strength and hardness.

Key Differences Between Solid Solution Strengthening and Precipitation Hardening

Solid solution strengthening disperses solute atoms uniformly within the crystal lattice, causing lattice distortion that impedes dislocation motion and enhances alloy strength. Precipitation hardening, however, relies on the formation of discrete, fine precipitates that act as obstacles to dislocation movement, providing higher strength increments by blocking slip more effectively. Key differences include the mechanism of strengthening--lattice distortion versus physical obstruction--and typical temperature ranges where each method is most effective, with solid solution strengthening often functioning at higher temperatures compared to precipitation hardening.

Typical Alloy Systems Using Solid Solution Strengthening

Typical alloy systems using solid solution strengthening include copper-nickel, aluminum-copper, and titanium alloys, where solute atoms distort the crystal lattice and impede dislocation motion. This mechanism enhances mechanical strength by creating lattice strain fields that interact with moving dislocations, improving yield strength and hardness. Solid solution strengthening is particularly effective in substitutional and interstitial alloys with significant atomic size differences.

Common Alloys Utilizing Precipitation Hardening

Precipitation hardening is widely employed in aluminum alloys such as 7075 and 2024, as well as in nickel-based superalloys like Inconel 718, to enhance mechanical strength through finely dispersed precipitates within the metal matrix. These alloys leverage coherent precipitates that impede dislocation motion, significantly increasing yield strength and hardness compared to solid solution strengthening mechanisms. The ability to control precipitate size, shape, and distribution makes precipitation hardening a critical process in aerospace and automotive industries for lightweight yet high-strength components.

Microstructural Changes in Solid Solution Strengthening

Solid solution strengthening enhances alloy strength by introducing solute atoms into the solvent metal's crystal lattice, causing lattice distortions that hinder dislocation movement. These atomic-scale distortions create localized stress fields, increasing the resistance to plastic deformation without forming new phases. The resulting microstructural change is a homogeneous single-phase solid solution with uniformly distributed solute atoms that effectively impede dislocation glide.

Microstructural Evolution in Precipitation Hardening

Precipitation hardening significantly enhances alloy strength through controlled microstructural evolution, where finely dispersed precipitates form within the metal matrix, obstructing dislocation motion. This process involves nucleation, growth, and coarsening of precipitates such as gamma prime (g') in nickel-based superalloys, which are critical for maintaining high-temperature strength. The evolution of coherent, semi-coherent, or incoherent precipitates directly influences mechanical properties by optimizing the balance between hardness and ductility.

Mechanical Properties: Comparing Strengthening Methods

Solid solution strengthening improves alloy strength by dissolving alloying elements into the base metal, causing lattice distortions that hinder dislocation movement and enhance tensile strength and hardness. Precipitation hardening forms fine, dispersed particles within the metal matrix, which effectively block dislocations and significantly increase yield strength and wear resistance. Compared to solid solution strengthening, precipitation hardening typically provides superior mechanical properties in terms of strength and durability in aerospace and automotive alloys.

Industrial Applications and Case Studies

Solid solution strengthening enhances alloy durability by dissolving solute atoms into the base metal, effectively improving yield strength without significantly compromising ductility, making it ideal for structural components in aerospace and automotive industries. Precipitation hardening involves the formation of fine, dispersed particles within the alloy matrix that obstruct dislocation motion, widely applied in aluminum and titanium alloys for critical aerospace engine parts and high-performance automotive components. Industrial case studies demonstrate that combining both mechanisms in alloys like 7075 aluminum significantly optimizes mechanical properties, balancing strength, corrosion resistance, and fatigue life for demanding operational environments.

Solid Solution Strengthening vs Precipitation Hardening Infographic

materialdif.com

materialdif.com