Precipitation hardening alloys achieve strength through the formation of fine particles that hinder dislocation movement, resulting in enhanced hardness and mechanical properties after aging heat treatment. Solution hardening alloys rely on the distortion of the crystal lattice caused by solute atoms dissolved in the solvent metal, which impedes dislocation motion and increases strength without the need for subsequent heat treatment. Precipitation hardening offers higher strength and improved thermal stability compared to solution hardening, making it suitable for aerospace and automotive applications.

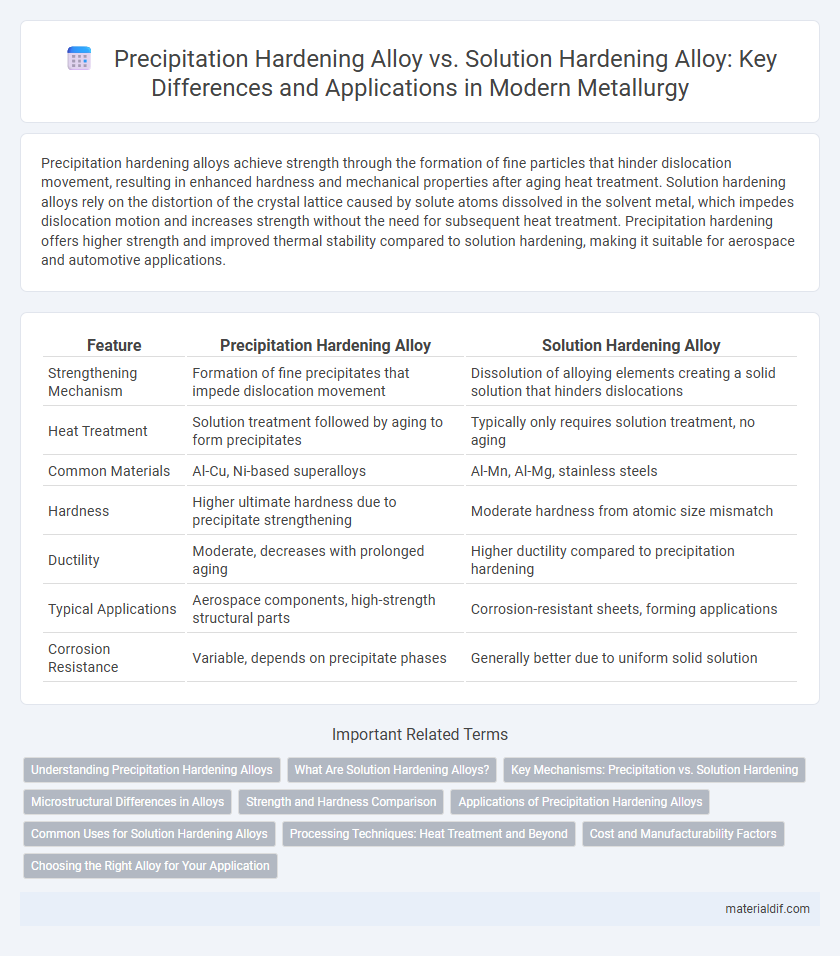

Table of Comparison

| Feature | Precipitation Hardening Alloy | Solution Hardening Alloy |

|---|---|---|

| Strengthening Mechanism | Formation of fine precipitates that impede dislocation movement | Dissolution of alloying elements creating a solid solution that hinders dislocations |

| Heat Treatment | Solution treatment followed by aging to form precipitates | Typically only requires solution treatment, no aging |

| Common Materials | Al-Cu, Ni-based superalloys | Al-Mn, Al-Mg, stainless steels |

| Hardness | Higher ultimate hardness due to precipitate strengthening | Moderate hardness from atomic size mismatch |

| Ductility | Moderate, decreases with prolonged aging | Higher ductility compared to precipitation hardening |

| Typical Applications | Aerospace components, high-strength structural parts | Corrosion-resistant sheets, forming applications |

| Corrosion Resistance | Variable, depends on precipitate phases | Generally better due to uniform solid solution |

Understanding Precipitation Hardening Alloys

Precipitation hardening alloys enhance strength through the controlled formation of fine particles within the metal matrix, which obstruct dislocation motion and improve mechanical properties. Common examples include age-hardened aluminum alloys, such as 2024 and 7075, widely used in aerospace for their high strength-to-weight ratios. This process involves solution treatment, quenching, and aging, differentiating it from solution hardening alloys that rely solely on solute atoms to impede dislocations without particle formation.

What Are Solution Hardening Alloys?

Solution hardening alloys strengthen metals by dissolving alloying elements uniformly within the base metal's crystal lattice, creating a single-phase solid solution that impedes dislocation movement and enhances mechanical properties. Commonly used elements like copper in aluminum or chromium in nickel-based alloys increase tensile strength and corrosion resistance without forming separate phases. This method contrasts with precipitation hardening, which relies on the formation of fine secondary phases to obstruct dislocations.

Key Mechanisms: Precipitation vs. Solution Hardening

Precipitation hardening alloys strengthen by forming finely dispersed particles within the metal matrix, which hinder dislocation motion and increase yield strength through particle-matrix interfaces. Solution hardening alloys rely on the uniform distribution of solute atoms in the solvent lattice that create lattice distortions, impeding dislocation movement and enhancing mechanical properties. The key distinction lies in precipitation hardening adopting a two-step heat treatment to precipitate phases, whereas solution hardening depends on maintaining solute atoms in solid solution during deformation.

Microstructural Differences in Alloys

Precipitation hardening alloys contain finely dispersed secondary phase particles that form within the metal matrix during controlled heat treatment, significantly enhancing strength by impeding dislocation motion. Solution hardening alloys rely on a homogeneous solid solution where solute atoms distort the lattice, increasing resistance to dislocation movement without forming distinct precipitates. The distinct microstructural difference lies in the presence of nanoscale precipitates in precipitation hardening alloys versus the uniform atomic distribution in solution hardening alloys.

Strength and Hardness Comparison

Precipitation hardening alloys exhibit higher strength and hardness than solution hardening alloys due to the formation of finely dispersed precipitates that impede dislocation motion more effectively. Solution hardening relies on the distortion of the metal lattice by solute atoms, which offers moderate strengthening but less resistance to deformation compared to precipitation hardening. The enhanced microstructural stability and particle strengthening mechanism of precipitation hardening alloys result in superior mechanical properties for high-performance applications.

Applications of Precipitation Hardening Alloys

Precipitation hardening alloys are extensively used in aerospace, automotive, and military applications due to their superior strength-to-weight ratio and excellent corrosion resistance. These alloys enable high-performance components such as turbine blades, aircraft structural parts, and armor plating by enhancing mechanical properties through controlled heat treatment processes. Their versatility in combining lightweight characteristics with enhanced hardness makes them ideal for critical, high-stress environments.

Common Uses for Solution Hardening Alloys

Solution hardening alloys are commonly used in aerospace components, automotive parts, and structural applications due to their enhanced strength and corrosion resistance. These alloys, such as aluminum-copper and stainless steel grades, benefit from uniform strengthening through alloying elements dissolved in the metal matrix. Their widespread application in manufacturing high-performance engine parts, turbine blades, and construction materials underscores their versatility and reliability.

Processing Techniques: Heat Treatment and Beyond

Precipitation hardening alloys undergo specialized heat treatments involving solutionizing, quenching, and aging to form finely dispersed precipitates that significantly enhance strength and hardness. Solution hardening alloys rely mainly on rapid quenching from high solution treatment temperatures to achieve a supersaturated solid solution, improving mechanical properties through atomic-level solute distribution. Beyond heat treatment, techniques such as cold working and aging control are critical for optimizing microstructure and mechanical performance in both alloy types.

Cost and Manufacturability Factors

Precipitation hardening alloys typically incur higher production costs due to complex heat treatment processes and precise alloying element composition, impacting manufacturability with extended processing times and specialized equipment requirements. Solution hardening alloys are generally more cost-effective, requiring simpler heat treatment and offering greater ease of fabrication and machining, which enhances manufacturing efficiency. Considering cost and manufacturability, solution hardening alloys are preferred in applications demanding economic scalability and simpler production workflows.

Choosing the Right Alloy for Your Application

Precipitation hardening alloys offer superior strength and hardness through controlled heat treatment, making them ideal for aerospace and automotive applications requiring high performance under stress. Solution hardening alloys provide enhanced ductility and corrosion resistance by dissolving alloying elements uniformly, suitable for marine and chemical environments. Selecting the right alloy depends on balancing mechanical properties and environmental conditions specific to the intended application.

Precipitation Hardening Alloy vs Solution Hardening Alloy Infographic

materialdif.com

materialdif.com