Duplex alloys combine both austenitic and ferritic phases, resulting in enhanced strength and corrosion resistance compared to single-phase alloys, which consist of only one microstructure. The dual-phase structure in duplex alloys offers improved mechanical properties and better resistance to stress corrosion cracking. Single-phase alloys may exhibit uniform characteristics, but they generally lack the balanced performance provided by the complex microstructure of duplex alloys.

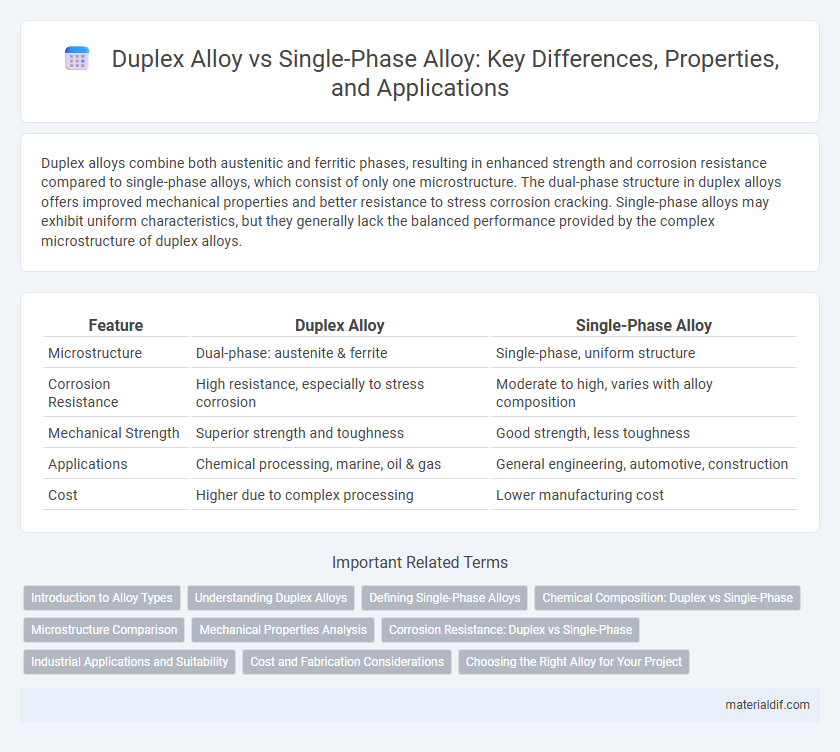

Table of Comparison

| Feature | Duplex Alloy | Single-Phase Alloy |

|---|---|---|

| Microstructure | Dual-phase: austenite & ferrite | Single-phase, uniform structure |

| Corrosion Resistance | High resistance, especially to stress corrosion | Moderate to high, varies with alloy composition |

| Mechanical Strength | Superior strength and toughness | Good strength, less toughness |

| Applications | Chemical processing, marine, oil & gas | General engineering, automotive, construction |

| Cost | Higher due to complex processing | Lower manufacturing cost |

Introduction to Alloy Types

Duplex alloys combine two distinct microstructures, typically austenite and ferrite, which enhance mechanical strength and corrosion resistance compared to single-phase alloys composed of only one microstructure, such as purely austenitic or ferritic types. The dual-phase nature of duplex alloys offers balanced properties making them ideal for demanding environments, whereas single-phase alloys provide uniform characteristics suitable for less aggressive applications. Understanding these fundamental differences aids in selecting the appropriate alloy type based on application-specific requirements for durability and performance.

Understanding Duplex Alloys

Duplex alloys combine a balanced microstructure of approximately 50% austenite and 50% ferrite phases, offering superior strength and corrosion resistance compared to single-phase alloys, which consist predominantly of either austenite or ferrite. This dual-phase composition enhances mechanical properties and improves resistance to stress corrosion cracking and pitting. Duplex alloys are widely used in chemical processing, marine, and oil and gas industries due to their optimal performance in harsh environments.

Defining Single-Phase Alloys

Single-phase alloys consist of a uniform microstructure with only one solid phase throughout, enhancing their homogeneity and isotropic mechanical properties. These alloys offer consistent corrosion resistance and predictable thermal behavior due to the absence of phase boundaries. Applications often favor single-phase alloys for their simplicity in processing and reliable performance under stress.

Chemical Composition: Duplex vs Single-Phase

Duplex alloys contain a balanced mixture of austenite and ferrite phases, typically with 40-60% ferrite, enhancing corrosion resistance and mechanical strength. Their chemical composition usually includes higher levels of chromium (18-28%), molybdenum (2-5%), and nitrogen compared to single-phase alloys, promoting duplex microstructure stability. Single-phase alloys, such as austenitic stainless steels, have a uniform phase with higher nickel content (6-25%) and lower ferrite, optimizing ductility but offering different corrosion and mechanical properties.

Microstructure Comparison

Duplex alloys feature a dual-phase microstructure combining austenite and ferrite, enhancing mechanical strength and corrosion resistance compared to single-phase alloys which contain only one microstructural phase, typically austenite. The balanced distribution of phases in duplex alloys results in improved toughness and susceptibility to stress corrosion cracking is significantly reduced. Single-phase alloys possess a homogeneous microstructure but often lack the superior combined properties offered by the duplex phase arrangement.

Mechanical Properties Analysis

Duplex alloys exhibit superior mechanical properties compared to single-phase alloys, combining enhanced strength and excellent corrosion resistance due to their dual-phase microstructure of austenite and ferrite. The presence of two phases in duplex alloys provides better toughness and fatigue resistance, making them ideal for demanding industrial applications. In contrast, single-phase alloys often have lower yield strength and reduced resilience under cyclic stress conditions, limiting their performance in high-stress environments.

Corrosion Resistance: Duplex vs Single-Phase

Duplex alloys, with their dual-phase microstructure of austenite and ferrite, offer superior corrosion resistance compared to single-phase alloys due to enhanced passivation and reduced susceptibility to stress corrosion cracking. Their balanced composition provides greater resistance to pitting and crevice corrosion in aggressive environments, such as chloride-rich conditions. In contrast, single-phase alloys typically exhibit lower resilience under similar corrosive stresses, making duplex alloys the preferred choice for demanding applications requiring long-term durability.

Industrial Applications and Suitability

Duplex alloys exhibit a dual-phase microstructure combining austenite and ferrite, offering superior strength, corrosion resistance, and stress corrosion cracking resistance compared to single-phase alloys, making them ideal for harsh industrial environments such as chemical processing and offshore applications. Single-phase alloys, typically consisting of either austenitic or ferritic structures, provide easier fabrication and better ductility but generally lower mechanical strength and corrosion resistance. The choice between duplex and single-phase alloys hinges on specific industrial requirements including mechanical load, exposure to corrosive agents, and welding considerations.

Cost and Fabrication Considerations

Duplex alloys offer enhanced strength and corrosion resistance compared to single-phase alloys, but their complex microstructure increases fabrication costs due to specialized processing techniques. Single-phase alloys typically require less expensive manufacturing and simpler heat treatments, resulting in lower overall production expenses. Choosing between duplex and single-phase alloys depends on balancing initial fabrication costs against long-term performance and maintenance savings.

Choosing the Right Alloy for Your Project

Duplex alloys combine austenitic and ferritic microstructures, offering enhanced strength and corrosion resistance compared to single-phase alloys. Single-phase alloys, typically either fully austenitic or ferritic, provide uniform mechanical properties but may lack the balance of toughness and resistance found in duplex variants. Selecting the right alloy depends on project requirements such as environmental conditions, mechanical stress, and budget constraints to ensure optimal performance and longevity.

Duplex alloy vs Single-phase alloy Infographic

materialdif.com

materialdif.com