Alloy consists of two or more metals fused together to create a material with enhanced strength and durability, while composite materials combine different substances, such as fibers and resins, to achieve superior mechanical properties and reduced weight. Alloys typically exhibit uniform chemical composition and improved corrosion resistance, whereas composites offer tailored properties, including high stiffness and flexibility, depending on the matrix and reinforcement used. Choosing alloy or composite depends on the application's specific requirements for strength, weight, and environmental resistance.

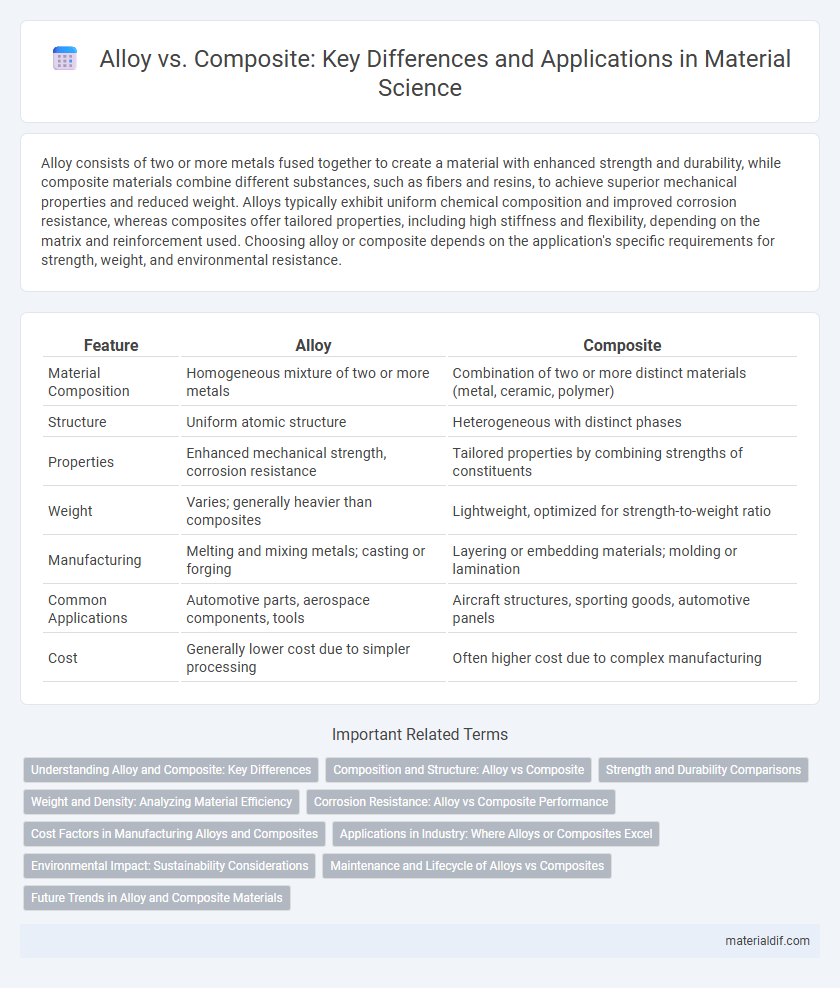

Table of Comparison

| Feature | Alloy | Composite |

|---|---|---|

| Material Composition | Homogeneous mixture of two or more metals | Combination of two or more distinct materials (metal, ceramic, polymer) |

| Structure | Uniform atomic structure | Heterogeneous with distinct phases |

| Properties | Enhanced mechanical strength, corrosion resistance | Tailored properties by combining strengths of constituents |

| Weight | Varies; generally heavier than composites | Lightweight, optimized for strength-to-weight ratio |

| Manufacturing | Melting and mixing metals; casting or forging | Layering or embedding materials; molding or lamination |

| Common Applications | Automotive parts, aerospace components, tools | Aircraft structures, sporting goods, automotive panels |

| Cost | Generally lower cost due to simpler processing | Often higher cost due to complex manufacturing |

Understanding Alloy and Composite: Key Differences

Alloy and Composite are both design patterns used in software engineering, but Alloy primarily focuses on describing and analyzing structural properties of systems through formal specifications, while Composite emphasizes managing hierarchical tree structures by treating individual objects and compositions uniformly. Alloy enables precise modeling with a declarative language and automated analysis for consistency checking, whereas Composite facilitates flexible object composition and transparency in client code interactions. Understanding these differences helps in choosing Alloy for system verification and Composite for building user interfaces or complex recursive structures.

Composition and Structure: Alloy vs Composite

Alloy is a lightweight modeling language focusing on structural composition using signatures and relations to represent components and their interactions, enabling formal analysis through constraint solving. Composite design pattern emphasizes hierarchical object composition, allowing clients to treat individual objects and compositions uniformly within object-oriented programming contexts. Alloy's declarative syntax excels at specifying complex structures abstractly, while Composite primarily guides runtime object composition and behavior management in software design.

Strength and Durability Comparisons

Alloy materials exhibit superior strength and durability compared to composite materials due to their homogeneous metal structure, which allows for enhanced resistance to deformation and wear. Alloys, particularly those containing elements like chromium and nickel, maintain exceptional tensile strength and corrosion resistance under extreme conditions. Composite materials may offer better weight-to-strength ratios but generally lack the long-term durability and impact resistance found in high-quality alloys.

Weight and Density: Analyzing Material Efficiency

Alloy materials typically offer enhanced strength-to-weight ratios compared to composites, making them advantageous in applications where lightweight durability is essential. Alloys, such as aluminum or titanium, possess higher densities ranging from 2.7 to 4.5 g/cm3, whereas composites like carbon fiber have significantly lower densities around 1.6 g/cm3, resulting in superior weight efficiency. Material efficiency analyses reveal that composites often optimize structural weight reduction, while alloys deliver consistent density and mechanical performance under varying thermal and load conditions.

Corrosion Resistance: Alloy vs Composite Performance

Alloys generally exhibit higher corrosion resistance due to their metallic nature and the ability to form protective oxide layers, such as stainless steel's chromium content preventing rust. Composites, while lightweight and corrosion-resistant in certain environments, can degrade when exposed to UV radiation, moisture, or harsh chemicals over time. Selecting between alloy and composite materials requires evaluating the specific environmental conditions and desired longevity for optimal corrosion resistance.

Cost Factors in Manufacturing Alloys and Composites

Manufacturing alloys typically involves lower material and processing costs due to the widespread availability of raw metals and established smelting techniques, whereas composites often require expensive fibers and complex layering processes that increase production expenses. Tooling and fabrication for alloys benefit from standardized methods, resulting in reduced labor and energy costs compared to composites, which demand specialized equipment and skilled labor for curing and assembly. Cost efficiency in alloys is enhanced by faster production cycles, while composites, despite their higher initial investment, may offer long-term savings through improved performance and reduced maintenance.

Applications in Industry: Where Alloys or Composites Excel

Alloys excel in applications requiring high strength, corrosion resistance, and thermal stability, such as aerospace engines, automotive parts, and construction materials. Composites offer superior strength-to-weight ratios and corrosion resistance, making them ideal for aerospace structures, sporting goods, and wind turbine blades. Industries prioritize alloys for durability and heat tolerance, while composites are favored for lightweight and fatigue-resistant applications.

Environmental Impact: Sustainability Considerations

Alloy production generally demands high energy consumption and mining activities, contributing to significant carbon emissions and resource depletion compared to composite materials, which often leverage recycled or bio-based fibers for lower environmental impact. Composite manufacturing processes enable lightweight designs that improve fuel efficiency and reduce lifecycle emissions in automotive and aerospace applications. Sustainable alloy alternatives like aluminum-lithium alloys offer improved strength-to-weight ratios but still lag behind composites in overall environmental performance due to extraction and processing challenges.

Maintenance and Lifecycle of Alloys vs Composites

Alloys generally offer superior ease of maintenance due to their homogenous metallic structure, allowing for straightforward repairs such as welding or machining. Composites, while lightweight and corrosion-resistant, often require specialized techniques for damage detection and repair, increasing lifecycle management complexity. The durability of alloys in high-temperature or harsh environments typically results in longer service life compared to many composite materials, influencing overall lifecycle costs.

Future Trends in Alloy and Composite Materials

Future trends in alloy and composite materials emphasize lightweight designs and enhanced mechanical properties for aerospace and automotive industries. Advanced alloys incorporating nanostructures and smart composites with self-healing capabilities are gaining traction to improve durability and performance. Research in additive manufacturing techniques enables complex geometries and tailored material properties, accelerating innovation in both alloy and composite sectors.

Alloy vs Composite Infographic

materialdif.com

materialdif.com