Cast acrylic offers superior optical clarity and chemical resistance compared to injection molded acrylic, making it ideal for high-quality displays and lenses. Injection molded acrylic provides faster production speeds and lower costs, suitable for large-scale manufacturing of complex shapes. Both methods produce durable acrylic materials, but cast acrylic excels in precision and finish, while injection molding favors efficiency and volume.

Table of Comparison

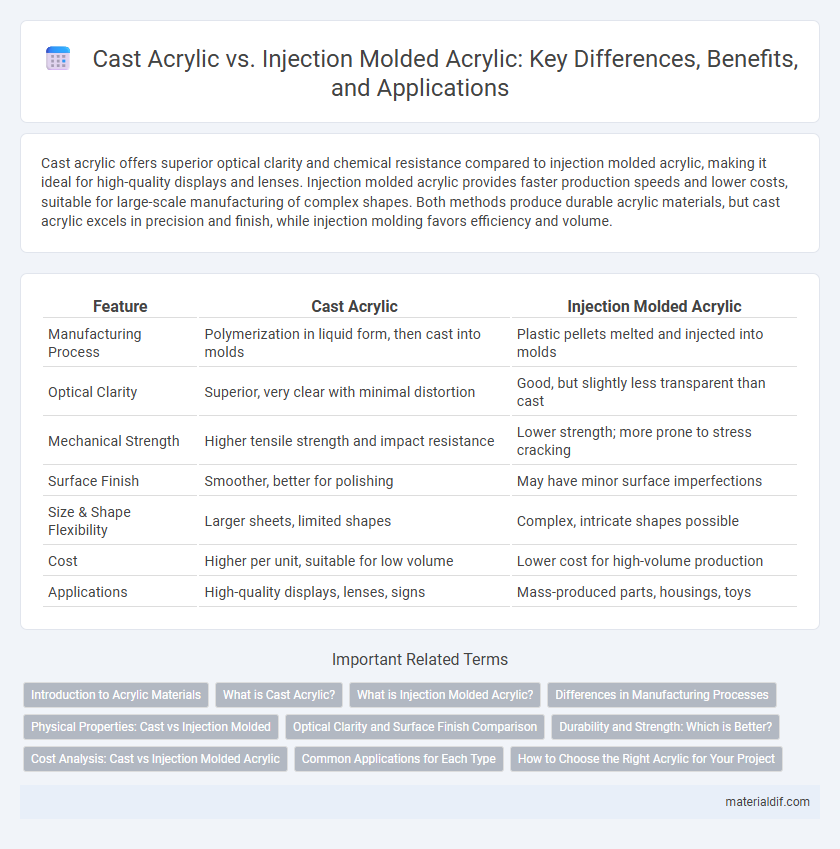

| Feature | Cast Acrylic | Injection Molded Acrylic |

|---|---|---|

| Manufacturing Process | Polymerization in liquid form, then cast into molds | Plastic pellets melted and injected into molds |

| Optical Clarity | Superior, very clear with minimal distortion | Good, but slightly less transparent than cast |

| Mechanical Strength | Higher tensile strength and impact resistance | Lower strength; more prone to stress cracking |

| Surface Finish | Smoother, better for polishing | May have minor surface imperfections |

| Size & Shape Flexibility | Larger sheets, limited shapes | Complex, intricate shapes possible |

| Cost | Higher per unit, suitable for low volume | Lower cost for high-volume production |

| Applications | High-quality displays, lenses, signs | Mass-produced parts, housings, toys |

Introduction to Acrylic Materials

Cast acrylic offers superior optical clarity and durability due to its slower curing process, making it ideal for high-quality displays and signage. Injection molded acrylic provides faster production times and cost efficiency by injecting molten acrylic into molds, suitable for complex shapes and high-volume manufacturing. Both materials share excellent weather resistance and UV stability, but cast acrylic generally delivers better scratch resistance and impact strength.

What is Cast Acrylic?

Cast acrylic is a type of acrylic produced by pouring liquid monomer into a mold where it polymerizes into solid sheets, resulting in superior optical clarity and thickness uniformity. This manufacturing process allows cast acrylic to exhibit higher resistance to solvents and better mechanical strength compared to injection molded acrylic. Cast acrylic's enhanced durability and ability to be precisely machined make it ideal for applications requiring high-quality visual transparency and structural integrity.

What is Injection Molded Acrylic?

Injection molded acrylic is a manufacturing process where liquid acrylic resin is heated and injected into a mold cavity under high pressure, allowing for rapid production of complex shapes with precise dimensions. This method results in durable, lightweight parts with excellent optical clarity and surface finish, commonly used in automotive components, electronic housings, and consumer products. Injection molded acrylic offers faster cycle times and higher volume output compared to cast acrylic, making it ideal for mass production.

Differences in Manufacturing Processes

Cast acrylic is produced through a batch process where liquid monomer is poured into molds and polymerized, resulting in thicker, clearer sheets with superior optical properties. Injection molded acrylic involves melting pellets and injecting the molten plastic into molds, allowing faster production and more complex shapes but with slightly lower optical clarity and strength. The manufacturing differences impact cost, quality, and application suitability for cast versus injection molded acrylic.

Physical Properties: Cast vs Injection Molded

Cast acrylic exhibits superior optical clarity and higher chemical resistance compared to injection molded acrylic, making it ideal for applications requiring durability and transparency. Injection molded acrylic offers faster production times and more complex shapes but tends to have lower molecular weight, resulting in reduced impact strength and less UV resistance. Physical properties such as density, tensile strength, and thermal resistance differ significantly, with cast acrylic typically providing enhanced mechanical performance and better surface hardness.

Optical Clarity and Surface Finish Comparison

Cast acrylic offers superior optical clarity with a higher light transmittance of up to 92%, making it ideal for applications requiring crystal-clear visibility such as lenses and display cases. Injection molded acrylic tends to have slightly lower optical clarity due to residual stresses from the molding process, often resulting in a haze or less uniform transparency. The surface finish of cast acrylic is generally smoother and more polished, while injection molded parts may exhibit minor imperfections or flow lines, impacting the overall aesthetic quality.

Durability and Strength: Which is Better?

Cast acrylic offers superior durability and strength due to its slower curing process, resulting in a denser and more impact-resistant material compared to injection molded acrylic. Injection molded acrylic, while more cost-effective and suitable for complex shapes, tends to have slightly lower tensile strength and is more prone to stress fractures. For applications requiring maximum toughness and longevity, cast acrylic remains the preferred choice.

Cost Analysis: Cast vs Injection Molded Acrylic

Cast acrylic offers higher material costs due to its superior optical clarity and durability, making it ideal for applications requiring precision and long-term performance. Injection molded acrylic features lower production expenses with faster cycle times, enabling cost-effective mass manufacturing for less demanding uses. Evaluating the cost-effectiveness depends on project volume, with cast acrylic favored for small batches and injection molded acrylic preferred for large-scale, high-volume production.

Common Applications for Each Type

Cast acrylic is commonly used for high-quality displays, signage, aquariums, and optical lenses due to its superior clarity, strength, and resistance to UV light. Injection molded acrylic is favored for mass-produced items like automotive parts, electronic housings, and small consumer goods because of its fast production times and ability to create complex shapes with consistent precision. Both types offer versatile solutions, but cast acrylic is preferred for visual excellence while injection molded acrylic excels in cost-effective manufacturing.

How to Choose the Right Acrylic for Your Project

Cast acrylic offers superior optical clarity, higher chemical resistance, and better machinability, making it ideal for applications requiring precision and durability such as optical lenses or display cases. Injection molded acrylic is more cost-effective for high-volume production, delivering consistent shapes with faster turnaround times, suitable for mass-produced components like automotive parts or consumer goods. Evaluate project requirements including clarity, durability, production volume, and budget to determine whether cast or injection molded acrylic best meets your performance and cost needs.

Cast Acrylic vs Injection Molded Acrylic Infographic

materialdif.com

materialdif.com