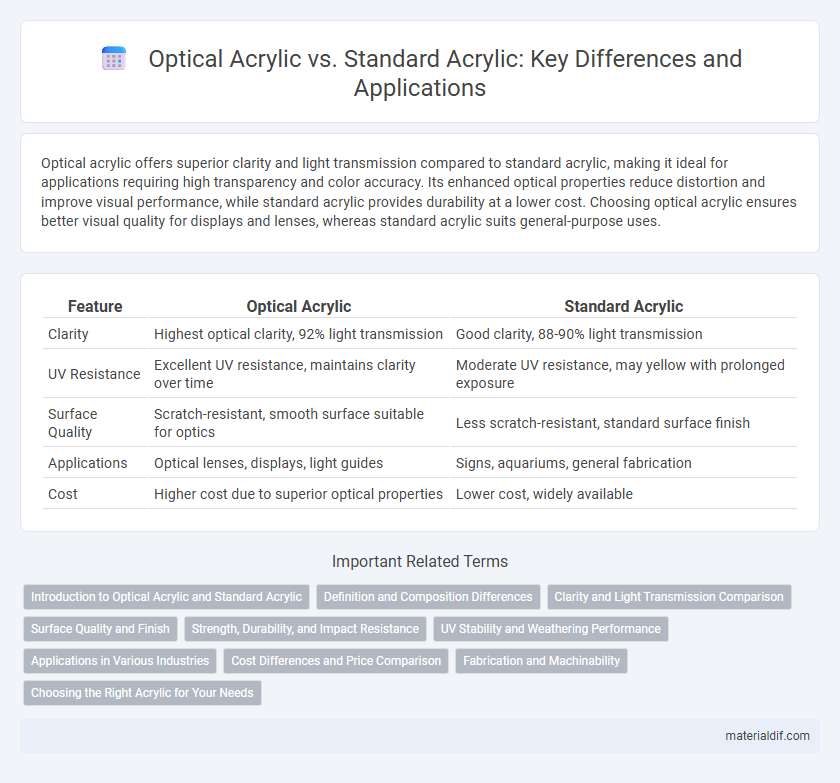

Optical acrylic offers superior clarity and light transmission compared to standard acrylic, making it ideal for applications requiring high transparency and color accuracy. Its enhanced optical properties reduce distortion and improve visual performance, while standard acrylic provides durability at a lower cost. Choosing optical acrylic ensures better visual quality for displays and lenses, whereas standard acrylic suits general-purpose uses.

Table of Comparison

| Feature | Optical Acrylic | Standard Acrylic |

|---|---|---|

| Clarity | Highest optical clarity, 92% light transmission | Good clarity, 88-90% light transmission |

| UV Resistance | Excellent UV resistance, maintains clarity over time | Moderate UV resistance, may yellow with prolonged exposure |

| Surface Quality | Scratch-resistant, smooth surface suitable for optics | Less scratch-resistant, standard surface finish |

| Applications | Optical lenses, displays, light guides | Signs, aquariums, general fabrication |

| Cost | Higher cost due to superior optical properties | Lower cost, widely available |

Introduction to Optical Acrylic and Standard Acrylic

Optical acrylic, also known as clear cast acrylic, offers superior clarity and light transmission compared to standard acrylic, making it ideal for applications requiring high optical performance. Standard acrylic features good strength and durability but may have slight haze or less transparency due to impurities and extrusion manufacturing processes. Both materials share similar chemical resistance and ease of fabrication, but optical acrylic is preferred in lenses, displays, and light guides where visual precision is critical.

Definition and Composition Differences

Optical acrylic is a specialized form of acrylic designed for high clarity and light transmission, typically having lower impurities and enhanced optical properties compared to standard acrylic. Standard acrylic consists of polymethyl methacrylate (PMMA) with general-purpose additives, leading to a broader range of uses but less optical precision. The difference in composition centers on purity levels and the inclusion of specific additives that improve refractive clarity in optical acrylic, making it ideal for lenses, screens, and optical devices.

Clarity and Light Transmission Comparison

Optical acrylic offers superior clarity compared to standard acrylic, boasting a light transmittance rate of approximately 92%, which closely rivals that of glass. Standard acrylic typically exhibits slightly lower clarity with light transmission around 88-90%, resulting in less crisp visual performance. This enhanced transparency in optical acrylic makes it ideal for applications requiring clear, distortion-free viewing such as lenses and display screens.

Surface Quality and Finish

Optical acrylic features superior surface quality with exceptional clarity, minimal distortion, and a smooth, polished finish ideal for high-precision applications such as lenses and displays. Standard acrylic often exhibits higher surface roughness and may contain minor imperfections, making it suitable for general-purpose uses where optical clarity is less critical. The advanced manufacturing processes in optical acrylic ensure enhanced transparency and durability compared to standard acrylic sheets.

Strength, Durability, and Impact Resistance

Optical Acrylic offers superior strength and impact resistance compared to Standard Acrylic, making it more durable in demanding applications. Its enhanced clarity and UV resistance maintain long-term optical performance without yellowing or cracking. Standard Acrylic, while versatile and cost-effective, is more prone to scratches and less capable of withstanding high-impact forces.

UV Stability and Weathering Performance

Optical acrylic exhibits superior UV stability compared to standard acrylic, significantly reducing yellowing and surface degradation over extended exposure to sunlight. Its enhanced weathering performance ensures clarity and mechanical integrity are maintained in harsh outdoor conditions, making it ideal for applications requiring prolonged durability. Standard acrylic, while cost-effective, tends to degrade faster under UV radiation, leading to compromised transparency and brittleness over time.

Applications in Various Industries

Optical acrylic offers superior clarity and light transmission compared to standard acrylic, making it ideal for precision applications in medical devices, optical lenses, and high-end display panels. Standard acrylic, with its cost-effectiveness and durability, is widely utilized in signage, automotive parts, and household products. The choice between optical and standard acrylic hinges on specific industry requirements for transparency, strength, and light diffusion.

Cost Differences and Price Comparison

Optical acrylic often commands a higher price than standard acrylic due to its superior clarity, light transmission of up to 92%, and precision manufacturing process that reduces impurities and defects. Standard acrylic is more cost-effective for general applications but typically exhibits lower optical quality and may contain minor imperfections affecting visual performance. Price differences can range from 20% to 50%, with optical acrylic preferred in display, lens, and optical instrument applications where clarity is critical.

Fabrication and Machinability

Optical acrylic offers superior clarity and minimal light distortion, making it ideal for precision applications requiring high-quality visual performance, while standard acrylic provides adequate transparency for general purposes. In terms of fabrication, optical acrylic demands careful machining with fine tools to prevent micro-cracks and maintain optical integrity, whereas standard acrylic is more forgiving and easier to cut, drill, and shape using conventional methods. The machinability of optical acrylic is best suited for industries like optics and medical devices, where precision and surface finish are critical, contrasting with standard acrylic's broader use in signs, displays, and protective barriers.

Choosing the Right Acrylic for Your Needs

Optical acrylic offers superior clarity and light transmission up to 92%, making it ideal for lenses, display cases, and high-precision optical applications. Standard acrylic provides excellent impact resistance and versatility at a lower cost, suitable for general signage, frames, and protective barriers. Selecting the right acrylic depends on balancing optical performance requirements with budget and structural needs.

Optical Acrylic vs Standard Acrylic Infographic

materialdif.com

materialdif.com