Acrylic glass offers superior impact resistance and flexibility compared to tempered glass, making it ideal for applications requiring lightweight and shatterproof materials. While tempered glass provides higher scratch resistance and a more polished appearance, acrylic glass is easier to fabricate and can be cut or drilled without compromising its structural integrity. Choosing between acrylic and tempered glass depends on the balance between durability, aesthetics, and project requirements.

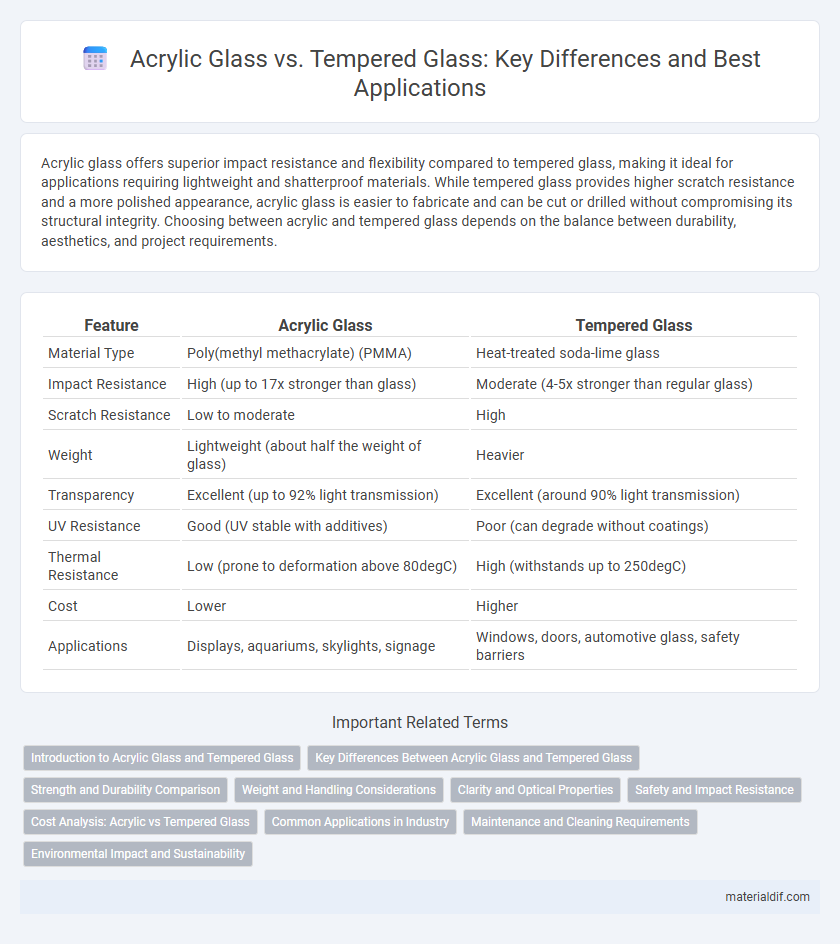

Table of Comparison

| Feature | Acrylic Glass | Tempered Glass |

|---|---|---|

| Material Type | Poly(methyl methacrylate) (PMMA) | Heat-treated soda-lime glass |

| Impact Resistance | High (up to 17x stronger than glass) | Moderate (4-5x stronger than regular glass) |

| Scratch Resistance | Low to moderate | High |

| Weight | Lightweight (about half the weight of glass) | Heavier |

| Transparency | Excellent (up to 92% light transmission) | Excellent (around 90% light transmission) |

| UV Resistance | Good (UV stable with additives) | Poor (can degrade without coatings) |

| Thermal Resistance | Low (prone to deformation above 80degC) | High (withstands up to 250degC) |

| Cost | Lower | Higher |

| Applications | Displays, aquariums, skylights, signage | Windows, doors, automotive glass, safety barriers |

Introduction to Acrylic Glass and Tempered Glass

Acrylic glass, known as polymethyl methacrylate (PMMA), is a lightweight, shatter-resistant alternative to traditional glass, praised for its clarity and UV resistance. Tempered glass undergoes a controlled thermal or chemical treatment to enhance strength and safety by causing it to crumble into small granular chunks upon breakage. Both materials are widely used in applications requiring durability and transparency, with acrylic glass offering superior impact resistance and tempered glass providing enhanced heat tolerance.

Key Differences Between Acrylic Glass and Tempered Glass

Acrylic glass is a lightweight, shatter-resistant material known for its exceptional clarity and ease of fabrication, while tempered glass is a heat-treated, durable product designed to withstand high impact and thermal stress. Acrylic glass offers superior UV resistance and flexibility, making it ideal for outdoor applications, whereas tempered glass excels in scratch resistance and safety, breaking into small, blunt pieces to reduce injury risk. The key differences include acrylic's lower weight and higher impact resistance compared to tempered glass's enhanced strength and thermal resistance.

Strength and Durability Comparison

Acrylic glass offers greater impact resistance and flexibility, making it less prone to shattering compared to tempered glass, which is harder but more brittle. Tempered glass provides superior scratch resistance and withstands higher temperatures, but it can break into small granular pieces under extreme stress. The strength of acrylic is about 10 to 24 times stronger than ordinary glass, while tempered glass is approximately four to five times stronger, balancing weight, durability, and safety for various applications.

Weight and Handling Considerations

Acrylic glass is significantly lighter than tempered glass, weighing approximately half as much per square foot, which enhances ease of handling and installation. Its lightweight nature reduces stress on supporting frames and minimizes the risk of injury during transport and assembly. Tempered glass, although heavier and more fragile during handling, offers superior impact resistance and shatters into small, less dangerous pieces when broken.

Clarity and Optical Properties

Acrylic glass offers superior optical clarity with a light transmission rate of approximately 92%, surpassing tempered glass which transmits around 80-85%. Unlike tempered glass, acrylic does not undergo heat treatment that can cause slight distortion or haze, preserving its crystal-clear appearance. The inherent molecular structure of acrylic ensures minimal light refraction, making it ideal for applications requiring high visual fidelity.

Safety and Impact Resistance

Acrylic glass offers superior impact resistance compared to tempered glass, making it less likely to shatter upon impact and reducing the risk of injury from sharp fragments. Tempered glass, while stronger under compression and heat-treated for durability, tends to break into small, blunt pieces that enhance safety but is more prone to cracking under high impact. For applications requiring both safety and high impact resistance, acrylic glass provides a more robust and shatter-resistant option.

Cost Analysis: Acrylic vs Tempered Glass

Acrylic glass generally costs 50-70% less than tempered glass while offering comparable clarity and impact resistance. Tempered glass prices are higher due to its heat treatment process, which enhances strength and safety but increases production expenses. For budget-sensitive projects requiring lightweight and shatter-resistant materials, acrylic is the more cost-effective option without significantly compromising durability.

Common Applications in Industry

Acrylic glass is widely used in industries such as signage, automotive, and retail displays due to its lightweight, impact resistance, and ease of fabrication. Tempered glass finds common applications in automotive windows, architectural glazing, and safety glass for electronic devices because of its superior strength and shatter-resistant properties. Both materials serve crucial roles in manufacturing, with acrylic favored for customizable, lightweight solutions and tempered glass preferred for safety-critical applications.

Maintenance and Cleaning Requirements

Acrylic glass requires gentle cleaning with a soft cloth and mild soap to prevent scratches, avoiding ammonia-based cleaners commonly used for tempered glass. Tempered glass is more resistant to scratches and can be cleaned with a wider range of household glass cleaners without damage. Maintaining acrylic glass involves more careful handling to preserve clarity, while tempered glass offers easier upkeep due to its durability and scratch resistance.

Environmental Impact and Sustainability

Acrylic glass, made from polymethyl methacrylate (PMMA), is lightweight and recyclable, offering lower energy consumption in production compared to tempered glass, which requires high-temperature heat treatment leading to greater carbon emissions. While acrylic is more prone to scratching and has a shorter lifespan, it generates less waste and can be reprocessed into new products, enhancing its sustainability profile. Tempered glass, although durable and resistant to impact, is less recyclable due to complex manufacturing processes and often ends in landfills, increasing its environmental footprint.

Acrylic Glass vs Tempered Glass Infographic

materialdif.com

materialdif.com