UV-stabilized acrylic offers superior protection against fading, yellowing, and brittleness caused by prolonged exposure to sunlight, making it ideal for outdoor applications. Non-UV acrylic lacks these protective additives, resulting in faster degradation and reduced lifespan when exposed to UV rays. Choosing UV-stabilized acrylic ensures durability and maintains clarity over time, enhancing both aesthetics and functionality.

Table of Comparison

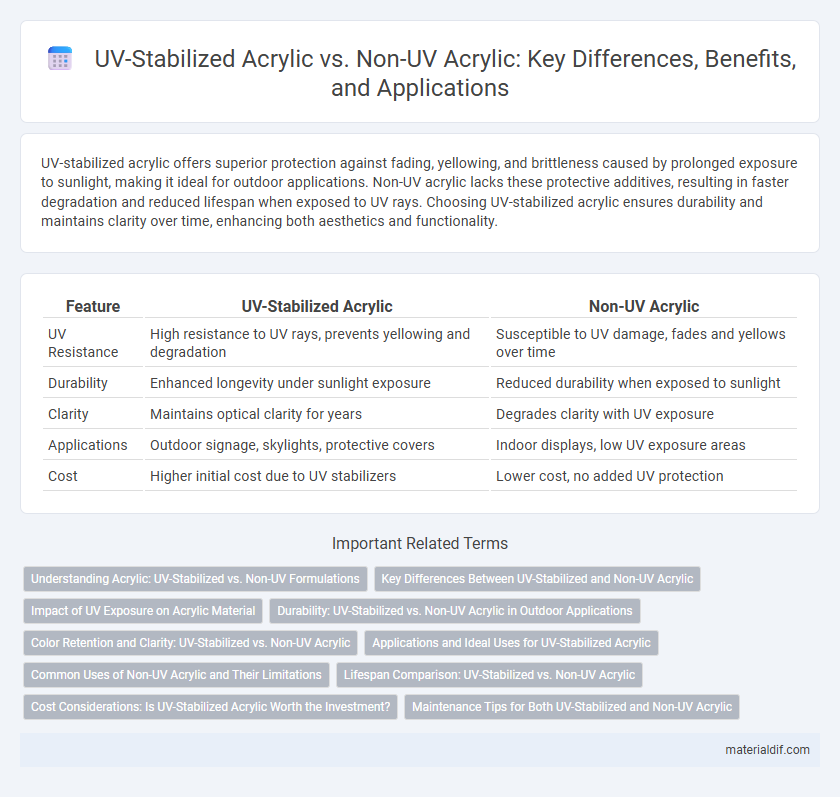

| Feature | UV-Stabilized Acrylic | Non-UV Acrylic |

|---|---|---|

| UV Resistance | High resistance to UV rays, prevents yellowing and degradation | Susceptible to UV damage, fades and yellows over time |

| Durability | Enhanced longevity under sunlight exposure | Reduced durability when exposed to sunlight |

| Clarity | Maintains optical clarity for years | Degrades clarity with UV exposure |

| Applications | Outdoor signage, skylights, protective covers | Indoor displays, low UV exposure areas |

| Cost | Higher initial cost due to UV stabilizers | Lower cost, no added UV protection |

Understanding Acrylic: UV-Stabilized vs. Non-UV Formulations

UV-stabilized acrylic incorporates additives that protect against ultraviolet radiation, significantly enhancing its resistance to yellowing, brittleness, and surface degradation over time. Non-UV acrylic lacks these protective compounds, making it more susceptible to fading, cracking, and loss of clarity when exposed to sunlight. Choosing UV-stabilized formulations ensures longer durability and color retention, especially for outdoor applications where prolonged UV exposure is common.

Key Differences Between UV-Stabilized and Non-UV Acrylic

UV-stabilized acrylic contains additives that protect against harmful ultraviolet rays, significantly reducing yellowing and degradation over time compared to non-UV acrylic. This enhanced durability makes UV-stabilized acrylic ideal for outdoor applications where prolonged sun exposure occurs. Non-UV acrylic, lacking these protective compounds, tends to become brittle and discolored more quickly when exposed to sunlight.

Impact of UV Exposure on Acrylic Material

UV-stabilized acrylic incorporates additives that protect the material from ultraviolet radiation, significantly reducing yellowing, brittleness, and surface degradation caused by prolonged sun exposure. Non-UV acrylic lacks these protective agents, making it vulnerable to fading, cracking, and loss of mechanical strength when exposed to UV light over time. The inclusion of UV stabilizers extends the durability and clarity of acrylic products used in outdoor applications, enhancing their lifespan and maintaining optical quality.

Durability: UV-Stabilized vs. Non-UV Acrylic in Outdoor Applications

UV-stabilized acrylic offers superior durability in outdoor applications by resisting yellowing, cracking, and brittleness caused by prolonged sun exposure, unlike non-UV acrylic which deteriorates faster under UV radiation. The incorporation of UV absorbers and stabilizers in UV-stabilized acrylic extends its lifespan, maintaining clarity and structural integrity for years. Non-UV acrylic typically shows signs of weathering within a few seasons, making it less reliable for long-term outdoor use.

Color Retention and Clarity: UV-Stabilized vs. Non-UV Acrylic

UV-stabilized acrylic maintains superior color retention and clarity over time by incorporating UV inhibitors that prevent yellowing and degradation caused by sun exposure. Non-UV acrylic lacks these protective additives, resulting in faster fading, discoloration, and a loss of transparency when exposed to prolonged ultraviolet radiation. Choosing UV-stabilized acrylic ensures long-lasting visual quality and durability, particularly in outdoor or high-sunlight environments.

Applications and Ideal Uses for UV-Stabilized Acrylic

UV-stabilized acrylic is specifically engineered to resist yellowing, cracking, and degradation caused by prolonged exposure to ultraviolet light, making it ideal for outdoor signage, skylights, and automotive applications. Non-UV acrylic lacks this protective feature and is better suited for indoor uses such as display cases and picture frames where UV exposure is minimal. The enhanced durability of UV-stabilized acrylic ensures longevity and maintained clarity in harsh sunlit environments.

Common Uses of Non-UV Acrylic and Their Limitations

Non-UV acrylic is commonly used for indoor applications such as picture frames, display cases, and protective barriers where prolonged sun exposure is minimal. Its affordability and clarity make it ideal for decorative and light-duty purposes but it lacks resistance to yellowing and brittleness when exposed to ultraviolet light over time. This limitation confines non-UV acrylic mainly to environments protected from direct sunlight to maintain its optical and structural integrity.

Lifespan Comparison: UV-Stabilized vs. Non-UV Acrylic

UV-stabilized acrylic significantly outperforms non-UV acrylic in lifespan, maintaining clarity and structural integrity for over 10 years under direct sunlight exposure. Non-UV acrylic often begins to yellow and degrade within 2 to 3 years due to prolonged UV radiation damage. The incorporation of UV inhibitors in UV-stabilized acrylic reduces photodegradation, making it ideal for outdoor applications requiring long-term durability.

Cost Considerations: Is UV-Stabilized Acrylic Worth the Investment?

UV-stabilized acrylic typically costs 20-30% more than non-UV acrylic due to added protective treatments that extend material lifespan by preventing yellowing and brittleness. Investing in UV-stabilized acrylic is cost-effective for outdoor applications or prolonged sun exposure, reducing replacement frequency and maintenance expenses. Non-UV acrylic may be suitable for indoor use where UV degradation is minimal, offering initial savings but potentially higher long-term costs.

Maintenance Tips for Both UV-Stabilized and Non-UV Acrylic

UV-stabilized acrylic requires less frequent cleaning and is more resistant to yellowing and surface degradation caused by prolonged sun exposure, making it ideal for outdoor applications. Non-UV acrylic demands more regular maintenance, including gentle cleaning with non-abrasive, mild detergents and protection from direct sunlight to prevent brittleness and discoloration. Both types benefit from avoiding abrasive materials, using soft cloths for cleaning, and storing in shaded or indoor environments to extend their lifespan.

UV-stabilized Acrylic vs Non-UV Acrylic Infographic

materialdif.com

materialdif.com