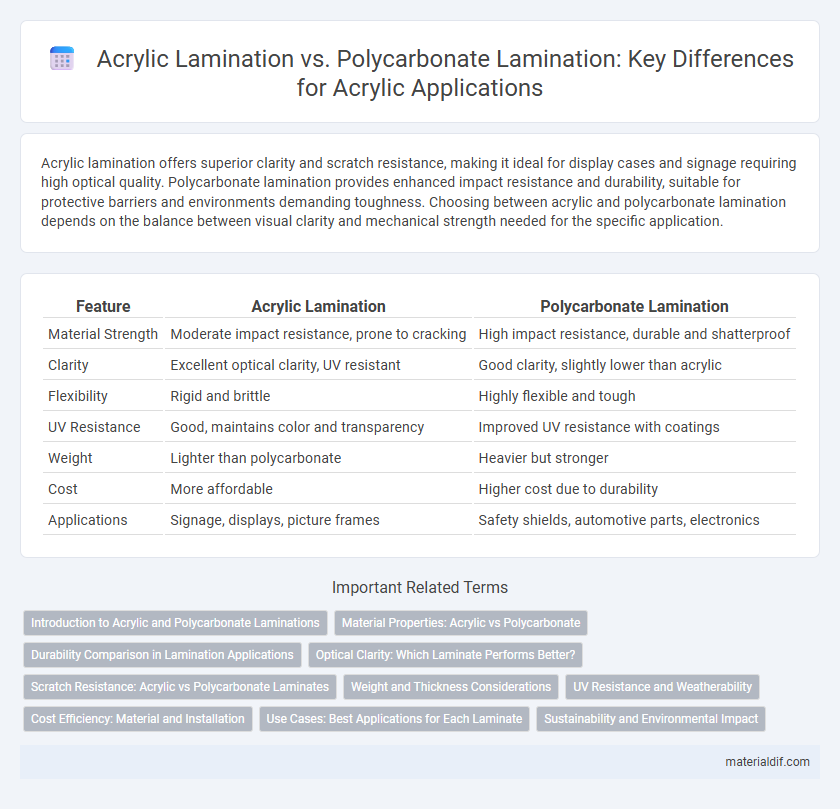

Acrylic lamination offers superior clarity and scratch resistance, making it ideal for display cases and signage requiring high optical quality. Polycarbonate lamination provides enhanced impact resistance and durability, suitable for protective barriers and environments demanding toughness. Choosing between acrylic and polycarbonate lamination depends on the balance between visual clarity and mechanical strength needed for the specific application.

Table of Comparison

| Feature | Acrylic Lamination | Polycarbonate Lamination |

|---|---|---|

| Material Strength | Moderate impact resistance, prone to cracking | High impact resistance, durable and shatterproof |

| Clarity | Excellent optical clarity, UV resistant | Good clarity, slightly lower than acrylic |

| Flexibility | Rigid and brittle | Highly flexible and tough |

| UV Resistance | Good, maintains color and transparency | Improved UV resistance with coatings |

| Weight | Lighter than polycarbonate | Heavier but stronger |

| Cost | More affordable | Higher cost due to durability |

| Applications | Signage, displays, picture frames | Safety shields, automotive parts, electronics |

Introduction to Acrylic and Polycarbonate Laminations

Acrylic lamination offers superior clarity and UV resistance, making it ideal for displays and protective coverings where transparency is critical. Polycarbonate lamination provides enhanced impact resistance and durability, suitable for applications requiring robust protection against physical damage. Both materials serve as effective laminates but differ in strength and optical properties, influencing their selection based on specific use cases.

Material Properties: Acrylic vs Polycarbonate

Acrylic offers superior optical clarity with a light transmission rate of approximately 92%, making it ideal for applications requiring high transparency. Polycarbonate exhibits greater impact resistance, about 250 times that of glass, and better heat resistance, withstanding temperatures up to PC reaches 115degC, compared to acrylic's limit of around 80degC. Both materials provide UV resistance, but acrylic tends to yellow less over time, while polycarbonate offers enhanced flexibility and durability in extreme conditions.

Durability Comparison in Lamination Applications

Acrylic lamination offers excellent scratch resistance and clarity, making it ideal for applications requiring high transparency and aesthetic appeal. Polycarbonate lamination provides superior impact resistance and toughness, outperforming acrylic in environments exposed to frequent mechanical stress or harsh conditions. Durability in lamination applications depends on balancing the need for optical quality with resistance to physical damage, where polycarbonate excels in strength and acrylic in surface hardness.

Optical Clarity: Which Laminate Performs Better?

Acrylic lamination offers superior optical clarity with a light transmittance of up to 92%, making it ideal for applications requiring clear, distortion-free visuals. Polycarbonate lamination, while more impact-resistant, typically transmits around 88-90% light and may introduce slight color distortion under certain conditions. For projects prioritizing crisp transparency and minimal haze, acrylic lamination outperforms polycarbonate in maintaining pure optical clarity.

Scratch Resistance: Acrylic vs Polycarbonate Laminates

Acrylic laminates exhibit superior scratch resistance compared to polycarbonate laminates, making them ideal for applications requiring durable surfaces. Polycarbonate laminates, while offering higher impact resistance, are more prone to surface scratches and require additional coatings for durability. Selecting acrylic laminates ensures enhanced longevity in environments where abrasion and surface wear are critical factors.

Weight and Thickness Considerations

Acrylic lamination typically offers a lighter weight option compared to polycarbonate lamination, making it preferable for applications where minimizing weight is crucial. In terms of thickness, acrylic sheets can be produced thinner while maintaining clarity, whereas polycarbonate lamination requires thicker layers to achieve similar impact resistance. These weight and thickness differences influence design decisions in industries such as automotive, signage, and protective glazing.

UV Resistance and Weatherability

Acrylic lamination offers superior UV resistance with exceptional clarity and long-lasting color retention, making it ideal for outdoor applications exposed to intense sunlight. Polycarbonate lamination provides enhanced impact resistance but tends to yellow and degrade faster under prolonged UV exposure, reducing its weatherability over time. For applications requiring long-term durability against harsh weather conditions, acrylic lamination is the preferred choice due to its stable performance in UV protection and environmental resilience.

Cost Efficiency: Material and Installation

Acrylic lamination offers a lower material cost compared to polycarbonate, making it a budget-friendly option for lightweight applications. Installation expenses for acrylic are generally reduced due to its easier cutting and shaping properties, which require less specialized labor and equipment. Polycarbonate, while more expensive upfront, may provide better long-term value in high-impact environments due to its durability, despite higher initial installation costs.

Use Cases: Best Applications for Each Laminate

Acrylic lamination excels in applications requiring excellent optical clarity and UV resistance, making it ideal for signage, displays, and protective coverings in outdoor environments. Polycarbonate lamination offers superior impact resistance and durability, suited for high-traffic areas, safety glazing, and protective barriers in industrial or security settings. Selecting between acrylic and polycarbonate lamination depends on the balance between transparency needs and mechanical strength requirements specific to the project.

Sustainability and Environmental Impact

Acrylic lamination offers a lower carbon footprint compared to polycarbonate due to its energy-efficient manufacturing process and higher recyclability rates. Polycarbonate lamination, while providing superior impact resistance, often involves more complex chemical treatments that can generate hazardous waste. Choosing acrylic lamination supports sustainability goals by reducing environmental pollutants and promoting easier end-of-life material recovery.

Acrylic Lamination vs Polycarbonate Lamination Infographic

materialdif.com

materialdif.com