Acrylic sheets typically range from 1/16 inch to 1 inch in thickness, offering excellent clarity and rigidity, while polycarbonate sheets commonly start at 1/8 inch and can exceed 1 inch, providing superior impact resistance. Acrylic's thinner options are suitable for applications requiring lightweight and scratch resistance, whereas polycarbonate's thicker gauges deliver enhanced durability and flexibility in more demanding environments. Choosing between the two depends on balancing the required strength, weight, and transparency for the specific project.

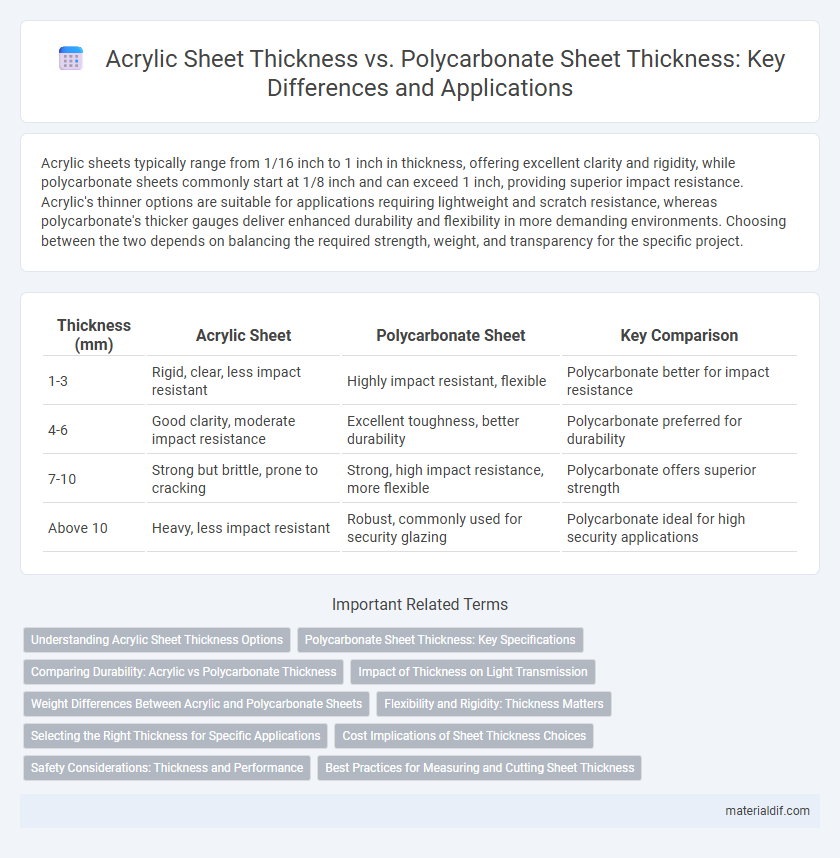

Table of Comparison

| Thickness (mm) | Acrylic Sheet | Polycarbonate Sheet | Key Comparison |

|---|---|---|---|

| 1-3 | Rigid, clear, less impact resistant | Highly impact resistant, flexible | Polycarbonate better for impact resistance |

| 4-6 | Good clarity, moderate impact resistance | Excellent toughness, better durability | Polycarbonate preferred for durability |

| 7-10 | Strong but brittle, prone to cracking | Strong, high impact resistance, more flexible | Polycarbonate offers superior strength |

| Above 10 | Heavy, less impact resistant | Robust, commonly used for security glazing | Polycarbonate ideal for high security applications |

Understanding Acrylic Sheet Thickness Options

Acrylic sheet thickness options range from 1 mm to over 25 mm, offering versatility for applications requiring clarity and rigidity. Compared to polycarbonate sheets, which typically start thicker for impact resistance, acrylic provides a balance between lightweight properties and strength at varied thickness levels. Selecting the right acrylic sheet thickness depends on factors such as load-bearing requirements, environmental exposure, and fabrication needs.

Polycarbonate Sheet Thickness: Key Specifications

Polycarbonate sheet thickness ranges typically from 0.75 mm to 15 mm, offering superior impact resistance compared to acrylic sheets of similar thickness. Key specifications include high tensile strength of approximately 70 MPa and an ability to withstand temperatures from -40degC to 120degC, making polycarbonate ideal for applications requiring durability and thermal stability. Thickness variations influence optical clarity and UV resistance, with thicker polycarbonate sheets providing enhanced protection against environmental stressors.

Comparing Durability: Acrylic vs Polycarbonate Thickness

Polycarbonate sheets generally offer greater durability than acrylic sheets at equivalent thicknesses due to their higher impact resistance and flexibility. Acrylic sheets tend to be more brittle, making them more prone to cracking under stress, especially at thinner gauges. When selecting between acrylic and polycarbonate, consider that thicker polycarbonate sheets provide enhanced toughness and longevity for demanding applications.

Impact of Thickness on Light Transmission

Acrylic sheets typically offer higher light transmission rates, around 92%, which remains relatively stable across thicknesses from 1mm to 10mm, whereas polycarbonate sheets have slightly lower transmission, about 88%, with increased thickness causing more noticeable light diffusion. Thicker acrylic sheets maintain clarity and brightness, making them ideal for applications requiring optimal optical performance. Polycarbonate's increased thickness enhances impact resistance but results in a more significant reduction in light transmission and increased haze, affecting visual clarity.

Weight Differences Between Acrylic and Polycarbonate Sheets

Acrylic sheets typically have a lower density of around 1.18 g/cm3, making them generally lighter than polycarbonate sheets, which have a density near 1.2 g/cm3. When comparing equivalent thicknesses, polycarbonate sheets weigh slightly more due to their higher molecular weight and impact-resistant structure. The weight difference impacts handling and installation choices, especially for applications requiring frequent adjustments or transportation.

Flexibility and Rigidity: Thickness Matters

Acrylic sheet thickness typically ranges from 1mm to 10mm, providing moderate rigidity but less flexibility compared to polycarbonate sheets of similar thickness, which range from 0.75mm to 12mm and offer superior impact resistance and flexibility. Thicker acrylic sheets increase stiffness and reduce bendability, making them ideal for applications requiring hardness and clarity, while thicker polycarbonate sheets maintain better flexibility for curved or dynamic installations. Selecting the right thickness balances durability and shape adaptability, with polycarbonate excelling in scenarios demanding both toughness and flexibility.

Selecting the Right Thickness for Specific Applications

Selecting the right thickness for acrylic sheets depends on factors like load-bearing requirements, transparency, and durability, with common thicknesses ranging from 1mm to 25mm for various applications. Polycarbonate sheets typically offer greater impact resistance at thinner gauges, often available between 0.75mm and 12mm, making them ideal for high-impact or safety-critical installations. Choosing between acrylic and polycarbonate sheet thickness involves balancing clarity, strength, and flexibility to meet specific needs such as glazing, signage, or protective barriers.

Cost Implications of Sheet Thickness Choices

Acrylic sheet thickness generally costs less per unit compared to polycarbonate, making thinner acrylic sheets a budget-friendly option for projects requiring clarity and rigidity without high impact resistance. Thicker polycarbonate sheets, while more expensive, offer superior durability and impact resistance, justifying the higher initial investment in environments demanding robust performance. Selecting the appropriate sheet thickness balances upfront material costs with long-term durability and maintenance expenses, influencing overall project budget efficiency.

Safety Considerations: Thickness and Performance

Acrylic sheets typically require greater thickness than polycarbonate sheets to achieve similar impact resistance, influencing safety performance in applications such as protective barriers and glazing. Polycarbonate's superior strength allows thinner sheets to provide robust protection against impacts, reducing weight while enhancing safety. When selecting sheet thickness, balancing material properties with safety standards ensures optimal performance in environments where durability and impact resistance are critical.

Best Practices for Measuring and Cutting Sheet Thickness

Acrylic sheet thickness typically ranges from 1/16 inch to 1 inch, while polycarbonate sheets usually vary from 1/32 inch to 1 inch, impacting their cutting and measurement methods. Best practices for measuring involve using precise calipers to ensure accurate thickness readings, and when cutting, employing fine-tooth blades designed for plastics to minimize chipping and cracking. Proper support and slow, steady cutting speeds enhance edge quality and maintain structural integrity in both acrylic and polycarbonate sheets.

Acrylic Sheet Thickness vs Polycarbonate Sheet Thickness Infographic

materialdif.com

materialdif.com