Acrylic offers superior impact resistance compared to glass, making it less likely to crack or break under sudden force. Its shatter resistance ensures that if it does break, it fractures into larger, duller pieces rather than sharp shards, enhancing safety. This combination of impact and shatter resistance makes acrylic an ideal choice for applications requiring durability and safety.

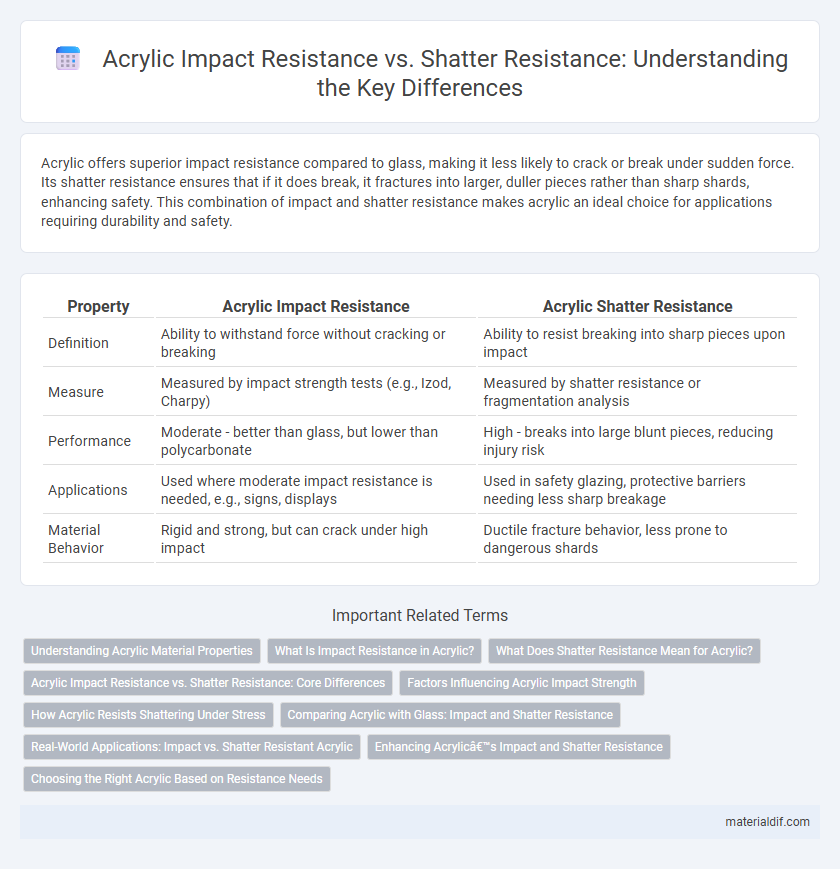

Table of Comparison

| Property | Acrylic Impact Resistance | Acrylic Shatter Resistance |

|---|---|---|

| Definition | Ability to withstand force without cracking or breaking | Ability to resist breaking into sharp pieces upon impact |

| Measure | Measured by impact strength tests (e.g., Izod, Charpy) | Measured by shatter resistance or fragmentation analysis |

| Performance | Moderate - better than glass, but lower than polycarbonate | High - breaks into large blunt pieces, reducing injury risk |

| Applications | Used where moderate impact resistance is needed, e.g., signs, displays | Used in safety glazing, protective barriers needing less sharp breakage |

| Material Behavior | Rigid and strong, but can crack under high impact | Ductile fracture behavior, less prone to dangerous shards |

Understanding Acrylic Material Properties

Acrylic offers excellent impact resistance, making it less likely to crack or break under sudden force compared to glass. Its shatter resistance is also notable, as it tends to fracture into larger, less hazardous pieces rather than tiny, sharp shards. Understanding these properties highlights acrylic's suitability for applications requiring durable, safe, and lightweight transparent materials.

What Is Impact Resistance in Acrylic?

Impact resistance in acrylic refers to the material's ability to absorb and withstand sudden forces or shocks without cracking or breaking. This property makes acrylic highly durable and suitable for applications such as protective barriers, eyewear lenses, and signage where unexpected impacts occur. Unlike shatter resistance, which describes how a material fragments upon breaking, impact resistance emphasizes the material's toughness and capacity to endure forceful impacts without catastrophic failure.

What Does Shatter Resistance Mean for Acrylic?

Shatter resistance in acrylic refers to its ability to withstand sudden impacts or stresses without breaking into sharp, dangerous shards, making it safer than glass in many applications. This material's inherent flexibility allows it to absorb and disperse energy, reducing the likelihood of catastrophic failure. Understanding shatter resistance is crucial for selecting acrylic in environments requiring durable, impact-tolerant materials such as protective barriers and glazing.

Acrylic Impact Resistance vs. Shatter Resistance: Core Differences

Acrylic impact resistance refers to the material's ability to absorb and withstand sudden forces without cracking, making it more durable under stress compared to glass. Shatter resistance focuses on the likelihood of the material breaking into sharp pieces when fractured, with acrylic exhibiting superior shatter resistance due to its flexibility and toughness. The core difference lies in impact resistance measuring force absorption capacity, while shatter resistance addresses the safety aspect by preventing hazardous shards.

Factors Influencing Acrylic Impact Strength

Acrylic impact resistance is primarily influenced by factors such as thickness, molecular weight, and polymer chain alignment, which enhance its ability to absorb and dissipate energy upon impact. Surface treatments and additives like plasticizers also play a crucial role in increasing impact strength by improving flexibility and reducing brittleness. Environmental conditions, including temperature and UV exposure, can significantly affect acrylic's shatter resistance by altering its structural integrity and stress distribution.

How Acrylic Resists Shattering Under Stress

Acrylic exhibits high impact resistance due to its molecular structure, which allows it to absorb and disperse energy without cracking. Unlike glass, acrylic deforms slightly under stress, preventing sudden shattering and enhancing safety in applications. Its ability to maintain structural integrity under impact makes it a preferred material for protective barriers, lenses, and safety glazing.

Comparing Acrylic with Glass: Impact and Shatter Resistance

Acrylic exhibits significantly higher impact resistance than glass, with the ability to absorb up to 17 times more force before breaking, making it less prone to cracking under pressure. Glass, while offering superior shatter resistance through tempered or laminated varieties, tends to break into sharp shards that can pose safety hazards. The superior impact resistance of acrylic makes it a preferred material in applications requiring durability and safety, such as protective barriers and glazing.

Real-World Applications: Impact vs. Shatter Resistant Acrylic

Acrylic impact resistance is critical in applications like safety shields and protective barriers where repeated force absorption is necessary, while shatter resistance ensures the material breaks into less harmful fragments, crucial in automotive and architectural glazing. Impact-resistant acrylic withstands sudden hits without cracking, making it ideal for high-traffic environments, whereas shatter-resistant acrylic prioritizes minimizing injury risk by preventing dangerous shards. Real-world usage balances these properties depending on the need for durability versus safety, influencing material choice in construction, transportation, and consumer products.

Enhancing Acrylic’s Impact and Shatter Resistance

Acrylic's impact resistance refers to its ability to absorb energy and withstand sudden forces without cracking, while shatter resistance describes its tendency to break into large, sharp pieces upon failure. Enhancing acrylic's impact and shatter resistance involves incorporating additives like polycarbonate blends or using specialized formulations that improve toughness and flexibility. Surface treatments and multi-layer laminations further increase durability, making acrylic suitable for demanding applications requiring both high impact absorption and controlled fracture behavior.

Choosing the Right Acrylic Based on Resistance Needs

Acrylic offers superior impact resistance compared to traditional glass, making it ideal for applications requiring durability and safety. However, its shatter resistance should be carefully evaluated, as acrylic can crack under extreme stress despite its toughness. Selecting the right acrylic depends on balancing impact resistance with the expected environmental and mechanical conditions to ensure optimal performance and longevity.

Acrylic Impact Resistance vs Shatter Resistance Infographic

materialdif.com

materialdif.com