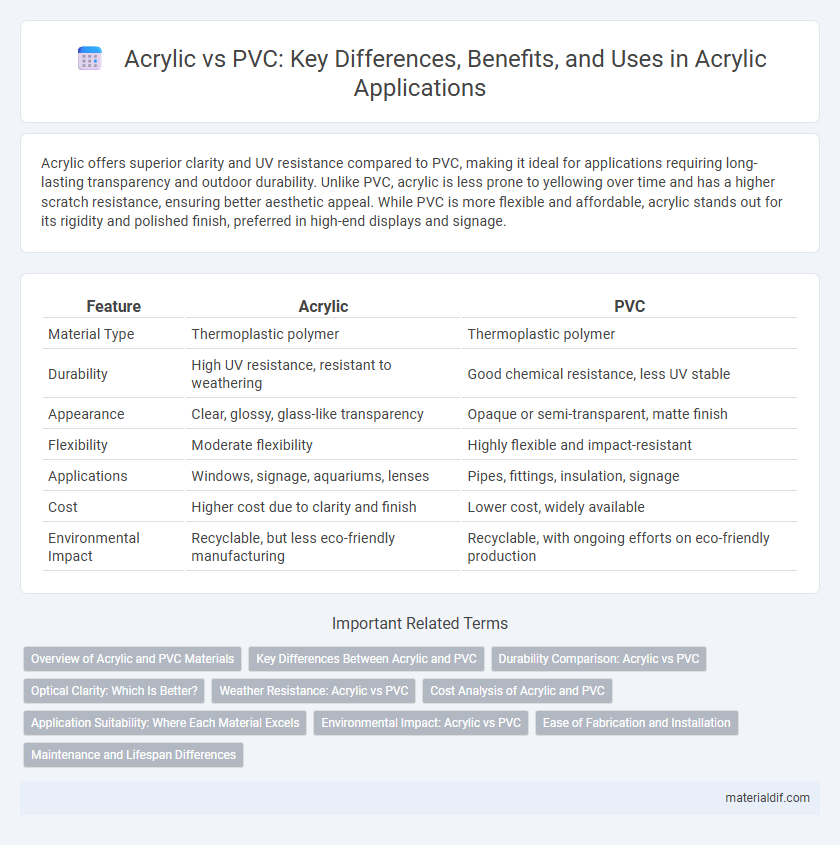

Acrylic offers superior clarity and UV resistance compared to PVC, making it ideal for applications requiring long-lasting transparency and outdoor durability. Unlike PVC, acrylic is less prone to yellowing over time and has a higher scratch resistance, ensuring better aesthetic appeal. While PVC is more flexible and affordable, acrylic stands out for its rigidity and polished finish, preferred in high-end displays and signage.

Table of Comparison

| Feature | Acrylic | PVC |

|---|---|---|

| Material Type | Thermoplastic polymer | Thermoplastic polymer |

| Durability | High UV resistance, resistant to weathering | Good chemical resistance, less UV stable |

| Appearance | Clear, glossy, glass-like transparency | Opaque or semi-transparent, matte finish |

| Flexibility | Moderate flexibility | Highly flexible and impact-resistant |

| Applications | Windows, signage, aquariums, lenses | Pipes, fittings, insulation, signage |

| Cost | Higher cost due to clarity and finish | Lower cost, widely available |

| Environmental Impact | Recyclable, but less eco-friendly manufacturing | Recyclable, with ongoing efforts on eco-friendly production |

Overview of Acrylic and PVC Materials

Acrylic, also known as polymethyl methacrylate (PMMA), is a transparent thermoplastic known for its clarity, weather resistance, and lightweight properties, making it ideal for signage, glazing, and display applications. PVC (polyvinyl chloride) is a versatile plastic characterized by its durability, chemical resistance, and affordability, widely used in piping, window frames, and vinyl flooring. Both materials offer distinct advantages: acrylic excels in optical clarity and UV resistance, while PVC provides superior impact strength and cost-effectiveness.

Key Differences Between Acrylic and PVC

Acrylic offers superior optical clarity and UV resistance compared to PVC, making it ideal for applications requiring transparency and weather durability. In contrast, PVC is more flexible, impact-resistant, and cost-effective, commonly used in plumbing and construction. The choice between acrylic and PVC hinges on factors like rigidity, environmental exposure, and visual clarity requirements.

Durability Comparison: Acrylic vs PVC

Acrylic offers superior durability compared to PVC, with higher resistance to UV light, weathering, and impact, making it ideal for outdoor applications and long-lasting installations. PVC tends to degrade faster under prolonged sun exposure, becoming brittle and prone to cracking over time. Acrylic's robustness ensures extended lifespan and reduced maintenance, outperforming PVC in durability and structural integrity.

Optical Clarity: Which Is Better?

Acrylic offers superior optical clarity compared to PVC, with light transmittance up to 92%, making it ideal for applications requiring crystal-clear visibility. PVC typically transmits about 82-85% of light, resulting in a slightly cloudier appearance that can affect visual quality. The higher refractive index and clarity of acrylic sheets make them preferred for glazing, display cases, and lenses where transparency is critical.

Weather Resistance: Acrylic vs PVC

Acrylic offers superior weather resistance compared to PVC, maintaining clarity and structural integrity under prolonged exposure to sunlight, rain, and temperature fluctuations. UV resistance in acrylic prevents yellowing and brittleness, making it ideal for outdoor applications. PVC, while durable, tends to degrade and discolor faster when exposed to harsh weather conditions, limiting its lifespan in exterior settings.

Cost Analysis of Acrylic and PVC

Acrylic generally costs more upfront compared to PVC due to its superior clarity and durability, making it a preferred choice for premium applications. PVC offers a lower initial investment with decent performance for budget-sensitive projects but may incur higher long-term maintenance costs. When analyzing total cost of ownership, acrylic's resistance to UV damage and weathering often results in better value over time despite the higher initial price.

Application Suitability: Where Each Material Excels

Acrylic excels in applications requiring high optical clarity and weather resistance, making it ideal for signage, aquariums, and skylights. PVC offers superior chemical resistance and durability in harsh environments, suited for plumbing, electrical insulation, and outdoor piping. Each material's unique properties determine its best use, with acrylic favored for aesthetic and transparency-focused projects, while PVC is chosen for structural and protective functions.

Environmental Impact: Acrylic vs PVC

Acrylic and PVC differ significantly in environmental impact, with acrylic being more eco-friendly due to its higher recyclability and lower emissions during production. PVC releases harmful dioxins and other toxic chemicals when manufactured and incinerated, contributing to environmental pollution and health risks. Choosing acrylic over PVC reduces carbon footprint and supports sustainable material use in construction and manufacturing industries.

Ease of Fabrication and Installation

Acrylic offers superior ease of fabrication and installation compared to PVC due to its lightweight nature and excellent machinability, allowing for precise cutting, drilling, and thermoforming without cracking. Unlike PVC, acrylic sheets bond seamlessly with solvent-based adhesives, reducing installation time and effort. The material's smooth surface and rigidity enable cleaner edges and faster fitting in applications ranging from signage to architectural panels.

Maintenance and Lifespan Differences

Acrylic offers superior UV resistance and retains color vibrancy longer than PVC, resulting in lower maintenance requirements over time. Unlike PVC, acrylic surfaces resist yellowing and cracking, extending their lifespan significantly, often lasting 10-15 years with minimal upkeep. Routine cleaning with mild soap preserves acrylic's clarity, whereas PVC may need more frequent replacement due to brittleness and discoloration.

Acrylic vs PVC Infographic

materialdif.com

materialdif.com