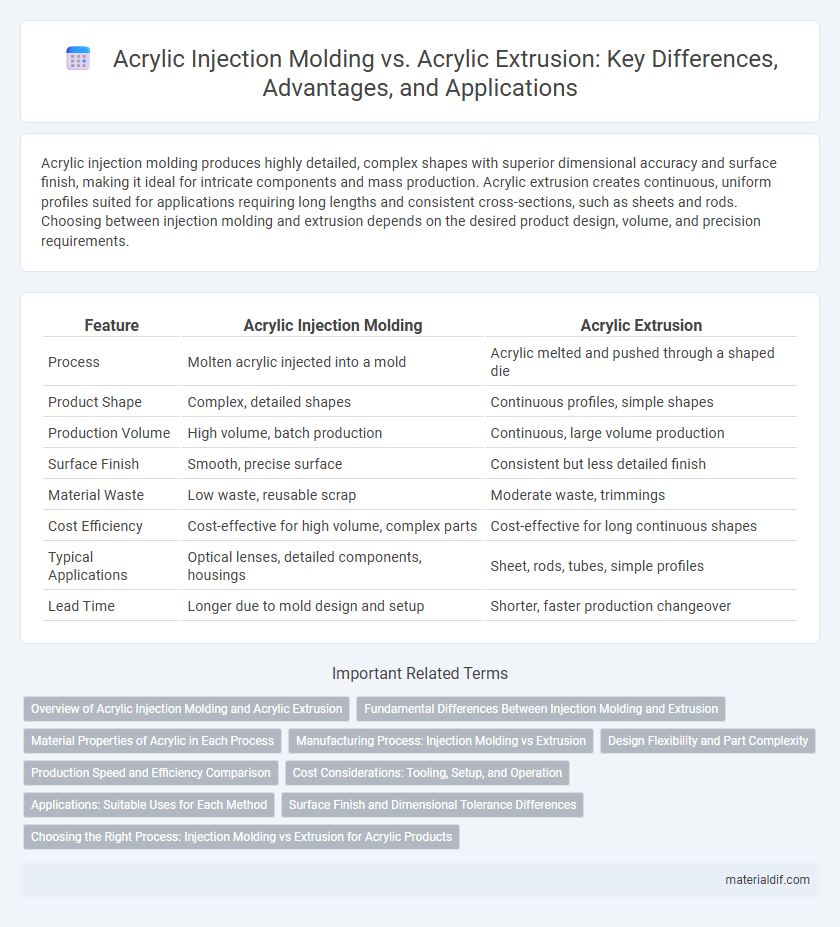

Acrylic injection molding produces highly detailed, complex shapes with superior dimensional accuracy and surface finish, making it ideal for intricate components and mass production. Acrylic extrusion creates continuous, uniform profiles suited for applications requiring long lengths and consistent cross-sections, such as sheets and rods. Choosing between injection molding and extrusion depends on the desired product design, volume, and precision requirements.

Table of Comparison

| Feature | Acrylic Injection Molding | Acrylic Extrusion |

|---|---|---|

| Process | Molten acrylic injected into a mold | Acrylic melted and pushed through a shaped die |

| Product Shape | Complex, detailed shapes | Continuous profiles, simple shapes |

| Production Volume | High volume, batch production | Continuous, large volume production |

| Surface Finish | Smooth, precise surface | Consistent but less detailed finish |

| Material Waste | Low waste, reusable scrap | Moderate waste, trimmings |

| Cost Efficiency | Cost-effective for high volume, complex parts | Cost-effective for long continuous shapes |

| Typical Applications | Optical lenses, detailed components, housings | Sheet, rods, tubes, simple profiles |

| Lead Time | Longer due to mold design and setup | Shorter, faster production changeover |

Overview of Acrylic Injection Molding and Acrylic Extrusion

Acrylic injection molding involves injecting molten acrylic into a mold to produce complex, high-precision parts with excellent dimensional accuracy and surface finish, ideal for detailed and custom applications. Acrylic extrusion forces melted acrylic through a shaped die to create continuous profiles like sheets and tubes, offering cost-effective production for simpler, uniform shapes with consistent thickness. Both processes optimize acrylic's optical clarity and weather resistance but cater to different design requirements and volume demands.

Fundamental Differences Between Injection Molding and Extrusion

Acrylic injection molding involves melting acrylic pellets and injecting the molten material into a mold cavity to create complex, high-precision shapes with excellent surface finishes, ideal for detailed parts and small production runs. Acrylic extrusion forces molten acrylic through a die to produce continuous profiles, sheets, or rods with consistent cross-sections, making it cost-effective for long-length products and large volume manufacturing. The fundamental differences lie in the process mechanics, with injection molding suited for intricate geometries and extrusion optimized for uniform, linear shapes.

Material Properties of Acrylic in Each Process

Acrylic injection molding produces parts with superior structural strength and intricate detail due to the high-pressure process that enhances molecular bonding, resulting in a more impact-resistant material. Acrylic extrusion yields continuous sheets or profiles with consistent thickness and excellent optical clarity, but typically exhibits lower tensile strength and impact resistance compared to injection-molded acrylic. The thermal stability of acrylic supports both processes, though injection molding offers better control over shrinkage and internal stresses, improving dimensional accuracy.

Manufacturing Process: Injection Molding vs Extrusion

Acrylic injection molding involves melting acrylic pellets and injecting the molten material into a mold cavity under high pressure, enabling the production of complex, detailed shapes with high precision and fast cycle times. In contrast, acrylic extrusion forces molten acrylic through a shaped die to create continuous profiles with consistent cross-sections, ideal for long, uniform parts but limited in geometric complexity. Injection molding requires precise mold design and higher tooling costs, while extrusion offers cost-effective production for simpler, linear components.

Design Flexibility and Part Complexity

Acrylic injection molding offers superior design flexibility and the ability to produce highly complex parts with intricate details and undercuts, making it ideal for precision applications. Acrylic extrusion, while cost-effective for producing continuous profiles and simpler shapes, is limited in creating complex geometries or detailed designs. Choosing between acrylic injection molding and extrusion depends on the required part complexity, with injection molding enabling more versatile design options.

Production Speed and Efficiency Comparison

Acrylic injection molding offers faster production cycles with high precision, making it ideal for complex, high-volume parts. Acrylic extrusion provides continuous, cost-effective output suitable for long, uniform profiles but operates at a slower overall speed compared to injection molding. Efficiency in injection molding excels with rapid cooling and minimal post-processing, whereas extrusion efficiency depends heavily on consistent material flow and lengthier production runs.

Cost Considerations: Tooling, Setup, and Operation

Acrylic injection molding involves higher initial tooling and setup costs due to custom molds and complex machinery, making it cost-effective only for large production runs. Acrylic extrusion offers lower tooling expenses with continuous profiles and quicker setup, suitable for medium to large quantities but less precise shapes. Operational costs for injection molding are generally higher because of energy-intensive processes, while extrusion provides more efficient, cost-effective production for simpler acrylic parts.

Applications: Suitable Uses for Each Method

Acrylic injection molding is ideal for producing complex, high-precision components like optical lenses, medical devices, and intricate consumer goods that require sharp detailing and consistent quality. Acrylic extrusion is best suited for creating continuous profiles such as sheets, rods, and tubes used in signage, displays, and lighting fixtures where uniform thickness and smooth surfaces are essential. Selecting the appropriate method depends on the application's design complexity, production volume, and required material properties.

Surface Finish and Dimensional Tolerance Differences

Acrylic injection molding produces parts with superior surface finish and intricate detail due to high-pressure filling of molds, resulting in smooth, glossy surfaces ideal for optical clarity. In contrast, acrylic extrusion offers consistent thickness but typically yields rougher surfaces requiring post-processing to achieve similar aesthetics. Dimensional tolerance in injection molding is tighter, often within +-0.1 mm, whereas extrusion tolerances are broader, around +-0.3 mm, impacting precision in complex applications.

Choosing the Right Process: Injection Molding vs Extrusion for Acrylic Products

Injection molding offers precise, complex shapes and high production rates, ideal for detailed acrylic parts like lenses and enclosures. Extrusion suits continuous profiles and sheets, delivering cost-efficient, uniform acrylic products for applications such as signage and glazing. Selecting between injection molding and extrusion depends on design complexity, volume, and product consistency requirements.

Acrylic Injection Molding vs Acrylic Extrusion Infographic

materialdif.com

materialdif.com