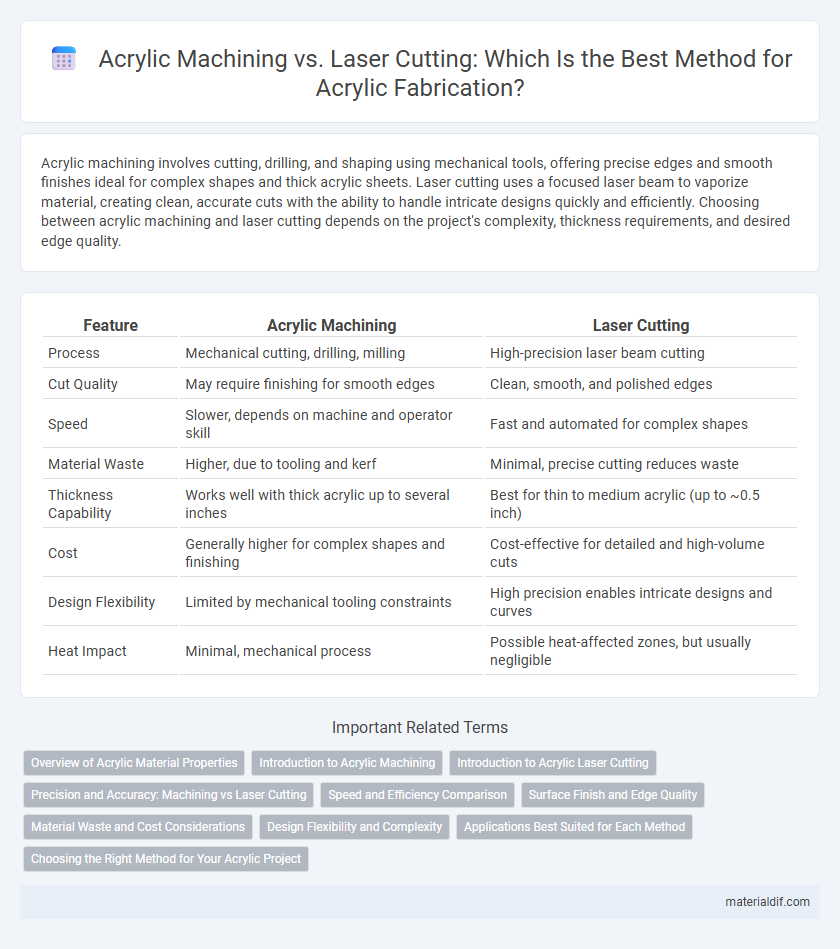

Acrylic machining involves cutting, drilling, and shaping using mechanical tools, offering precise edges and smooth finishes ideal for complex shapes and thick acrylic sheets. Laser cutting uses a focused laser beam to vaporize material, creating clean, accurate cuts with the ability to handle intricate designs quickly and efficiently. Choosing between acrylic machining and laser cutting depends on the project's complexity, thickness requirements, and desired edge quality.

Table of Comparison

| Feature | Acrylic Machining | Laser Cutting |

|---|---|---|

| Process | Mechanical cutting, drilling, milling | High-precision laser beam cutting |

| Cut Quality | May require finishing for smooth edges | Clean, smooth, and polished edges |

| Speed | Slower, depends on machine and operator skill | Fast and automated for complex shapes |

| Material Waste | Higher, due to tooling and kerf | Minimal, precise cutting reduces waste |

| Thickness Capability | Works well with thick acrylic up to several inches | Best for thin to medium acrylic (up to ~0.5 inch) |

| Cost | Generally higher for complex shapes and finishing | Cost-effective for detailed and high-volume cuts |

| Design Flexibility | Limited by mechanical tooling constraints | High precision enables intricate designs and curves |

| Heat Impact | Minimal, mechanical process | Possible heat-affected zones, but usually negligible |

Overview of Acrylic Material Properties

Acrylic exhibits excellent optical clarity, high impact resistance, and superior weatherability, making it a versatile material for both machining and laser cutting processes. Machining acrylic allows for precise mechanical shaping with smooth edges, while laser cutting provides intricate designs and sharp, clean cuts due to localized melting and vaporization. Understanding acrylic's thermal sensitivity and potential for chipping or melting is crucial when selecting the appropriate fabrication method to maintain material integrity.

Introduction to Acrylic Machining

Acrylic machining involves precise shaping and fabrication of acrylic sheets using tools such as CNC routers, drills, and saws to create custom parts with smooth edges and intricate details. This method offers superior control over thickness and depth compared to laser cutting, enabling complex designs and thicker material processing without causing heat-related stress or discoloration. It is ideal for applications requiring high structural integrity and polished finishes, such as signage, displays, and optical components.

Introduction to Acrylic Laser Cutting

Acrylic laser cutting leverages high-precision laser beams to achieve intricate designs and smooth edges, outperforming traditional acrylic machining in detail accuracy. The non-contact process reduces material stress and produces cleaner cuts, making it ideal for complex shapes and customized applications. Laser cutting also offers faster turnaround times and minimal finishing, enhancing production efficiency in acrylic fabrication.

Precision and Accuracy: Machining vs Laser Cutting

Acrylic machining offers high precision with the ability to create intricate, detailed designs through controlled mechanical cutting, ensuring consistent dimensional accuracy for complex parts. Laser cutting excels in precision by delivering clean, sharp edges and fine detail with minimal material distortion, especially effective for thin acrylic sheets. Both methods provide superior accuracy, but laser cutting typically achieves tighter tolerances and smoother finishes, optimizing quality for delicate or high-volume acrylic production.

Speed and Efficiency Comparison

Acrylic laser cutting offers superior speed and precision, enabling intricate designs to be completed in a fraction of the time compared to traditional acrylic machining. Machining involves slower, mechanical processes that may require multiple tool changes and generate more waste, reducing overall efficiency. Laser cutting minimizes material distortion and accelerates production, making it the preferred method for high-volume acrylic fabrication projects.

Surface Finish and Edge Quality

Acrylic machining produces smooth surfaces with minimal thermal impact, resulting in polished edges that often require less post-processing. Laser cutting offers precise cuts but can lead to slightly melted or frosted edges due to heat exposure, sometimes necessitating additional finishing for clarity. Choosing between the two depends on the desired edge quality and surface finish, with machining favored for superior clarity and laser cutting preferred for intricate shapes.

Material Waste and Cost Considerations

Acrylic machining typically produces more material waste due to the subtractive process involving cutting and shaping, which can increase overall costs. Laser cutting offers precise, clean cuts with minimal waste, enhancing material efficiency and reducing expenses. Cost considerations favor laser cutting for large-scale projects where material conservation is critical, while machining may be preferred for complex, detailed components despite higher waste.

Design Flexibility and Complexity

Acrylic machining offers enhanced design flexibility by enabling intricate 3D shapes, detailed engravings, and thicker material cuts with smoother edges. Laser cutting excels in precision and speed for flat acrylic sheets, producing complex 2D patterns and fine details with minimal heat distortion. Choosing between the two depends on project requirements, as machining supports more complex geometries, while laser cutting is ideal for high-volume, precise flat designs.

Applications Best Suited for Each Method

Acrylic machining excels in producing intricate, three-dimensional shapes and customized parts with high precision, making it ideal for applications such as display stands, medical devices, and aerospace components. Laser cutting offers exceptional speed and clean edges, best suited for flat or sheet acrylic used in signage, decorative panels, and packaging inserts. Choosing between these methods depends on the complexity, dimensional requirements, and production volume of the acrylic project.

Choosing the Right Method for Your Acrylic Project

Acrylic machining offers precise shaping and smooth edges ideal for intricate designs and thick materials, while laser cutting provides faster processing and highly detailed cuts suitable for thinner sheets and complex patterns. Selecting the right method depends on factors like project complexity, material thickness, budget constraints, and desired finish quality. For durable, clean cuts in heavy acrylic, machining is preferred, whereas laser cutting excels in speed and precision for delicate or decorative projects.

Acrylic Machining vs Laser Cutting Infographic

materialdif.com

materialdif.com