UV printing on acrylic offers superior detail and vibrant color accuracy compared to screen printing, making it ideal for complex designs and photo-quality images. Unlike screen printing, UV printing involves directly curing ink with ultraviolet light, resulting in a durable, scratch-resistant finish that adheres seamlessly to smooth acrylic surfaces. Screen printing, while cost-effective for large runs, often struggles with fine details and multiple color layers on acrylic, limiting its use for highly detailed or intricate visuals.

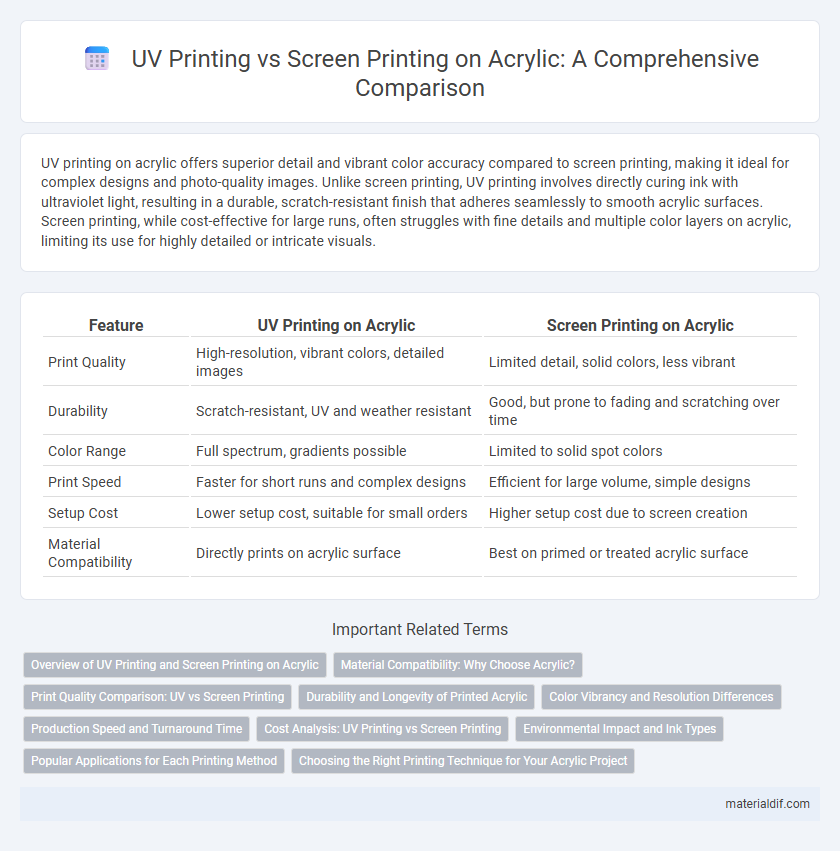

Table of Comparison

| Feature | UV Printing on Acrylic | Screen Printing on Acrylic |

|---|---|---|

| Print Quality | High-resolution, vibrant colors, detailed images | Limited detail, solid colors, less vibrant |

| Durability | Scratch-resistant, UV and weather resistant | Good, but prone to fading and scratching over time |

| Color Range | Full spectrum, gradients possible | Limited to solid spot colors |

| Print Speed | Faster for short runs and complex designs | Efficient for large volume, simple designs |

| Setup Cost | Lower setup cost, suitable for small orders | Higher setup cost due to screen creation |

| Material Compatibility | Directly prints on acrylic surface | Best on primed or treated acrylic surface |

Overview of UV Printing and Screen Printing on Acrylic

UV printing on acrylic utilizes ultraviolet light to cure ink instantly, producing sharp, vibrant images with high durability and resistance to fading. Screen printing on acrylic involves pushing ink through a mesh stencil onto the surface, offering excellent opacity and color saturation but typically less detail and longer drying times compared to UV printing. Both methods are widely used in signage and decorative applications, with UV printing favored for intricate designs and screen printing preferred for bold, solid colors.

Material Compatibility: Why Choose Acrylic?

UV printing on acrylic offers superior adherence and vibrant color reproduction due to its direct ink curing process, which bonds effectively with the smooth, non-porous surface of acrylic sheets. Screen printing on acrylic may require specialized inks and surface treatments to achieve durability, but both methods benefit from acrylic's excellent clarity, rigidity, and weather resistance. Choosing acrylic ensures optimal print quality and longevity, making it an ideal substrate for high-definition graphics and outdoor displays.

Print Quality Comparison: UV vs Screen Printing

UV printing on acrylic delivers superior print quality with vibrant colors, fine details, and smooth gradients due to its direct-to-surface technology and fast curing UV light. Screen printing on acrylic offers solid, durable colors but may struggle with intricate designs and color gradients because of the mesh stencil limitations. The choice between UV and screen printing on acrylic ultimately depends on the desired print resolution, color complexity, and production volume.

Durability and Longevity of Printed Acrylic

UV printing on acrylic offers superior durability with its ability to resist fading, scratching, and weathering thanks to the UV-cured inks that bond directly to the acrylic surface. Screen printing on acrylic provides a thick ink layer, but it is more prone to cracking and peeling over time, especially under prolonged exposure to sunlight and outdoor elements. For applications demanding long-lasting visual appeal and resistance to environmental wear, UV printing is generally considered the optimal choice.

Color Vibrancy and Resolution Differences

UV printing on acrylic offers superior color vibrancy and higher resolution compared to screen printing, producing crisp, detailed images with a wider color gamut. Screen printing tends to result in flatter, less vibrant colors due to its limited ink layering and lower resolution capabilities. The advanced technology of UV printing allows for intricate designs and sharp text, making it ideal for high-quality acrylic signage and displays.

Production Speed and Turnaround Time

UV printing on acrylic offers significantly faster production speed and shorter turnaround times due to its digital process, allowing for immediate print setup and minimal drying time. Screen printing on acrylic requires longer preparation, including creating screens and mask alignments, which increases overall production time. For projects with tight deadlines, UV printing provides a more efficient solution compared to the more labor-intensive screen printing method.

Cost Analysis: UV Printing vs Screen Printing

UV printing on acrylic offers lower setup costs compared to screen printing, making it ideal for small to medium print runs and customized designs. Screen printing involves higher initial setup expenses due to stencil creation and ink setup but becomes cost-effective for large volume orders. The choice between UV and screen printing on acrylic largely depends on print quantity and budget constraints, with UV printing providing flexibility and reduced costs for short runs.

Environmental Impact and Ink Types

UV printing on acrylic uses UV-curable inks that emit fewer volatile organic compounds (VOCs) and generate less hazardous waste compared to the solvent-based inks used in screen printing, making it a more environmentally friendly option. The ultraviolet light curing process in UV printing requires less energy and produces minimal air pollution, while screen printing often involves the use of harsh chemicals and solvents for ink preparation and cleanup. Choosing UV printing on acrylic supports sustainable practices by reducing toxic ink disposal and lowering overall environmental impact.

Popular Applications for Each Printing Method

UV printing on acrylic is widely used for vibrant, detailed graphics in applications such as signage, retail displays, and promotional products due to its ability to produce high-resolution images with durable color fidelity. Screen printing on acrylic is preferred for applications requiring bold, solid colors and durability, including industrial labels, automotive parts, and architectural panels. Both methods cater to different needs, with UV printing excelling in intricate designs and screen printing offering superior opacity and longevity on flat or textured acrylic surfaces.

Choosing the Right Printing Technique for Your Acrylic Project

UV printing on acrylic delivers sharp, detailed images with vibrant colors, making it ideal for projects requiring high-resolution graphics and rapid turnaround. Screen printing on acrylic offers durability and cost-effectiveness for larger runs, especially when using fewer colors or simpler designs. Evaluate project complexity, color requirements, budget, and production time to select the optimal printing technique for your acrylic application.

UV Printing on Acrylic vs Screen Printing on Acrylic Infographic

materialdif.com

materialdif.com