Acrylic displays offer superior clarity and scratch resistance compared to PETG displays, making them ideal for high-end presentations and long-term use. PETG displays provide enhanced impact resistance and flexibility, which allows for better durability in dynamic environments. Choosing between acrylic and PETG depends on the balance of optical quality and mechanical toughness needed for the specific display application.

Table of Comparison

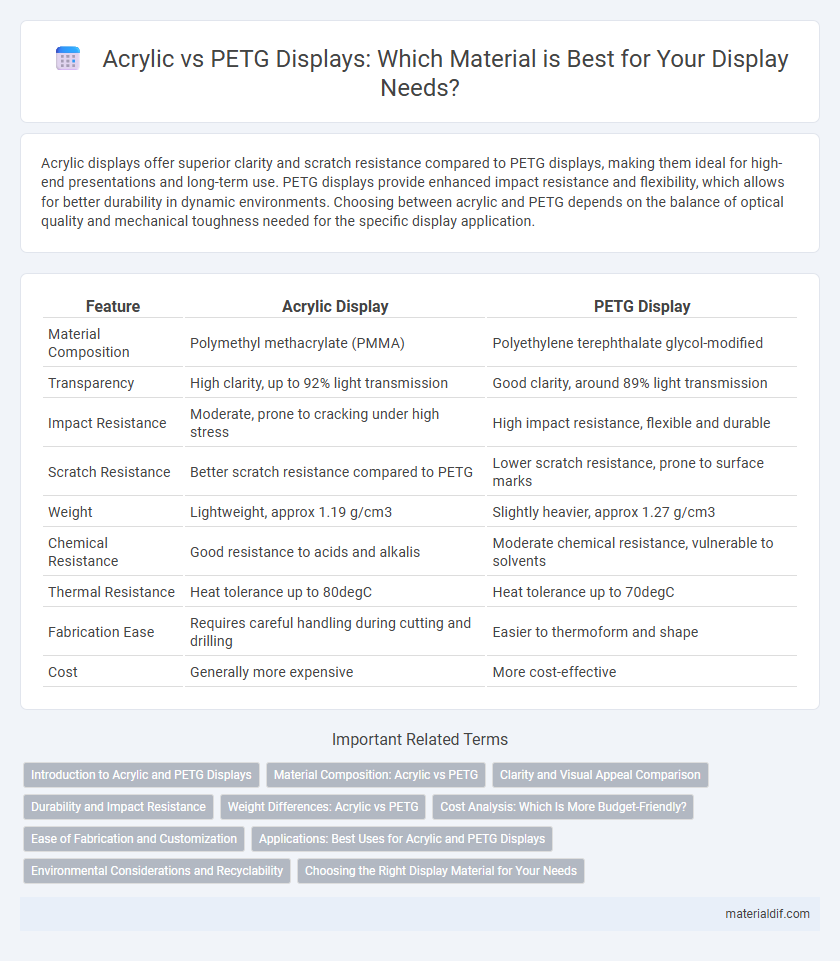

| Feature | Acrylic Display | PETG Display |

|---|---|---|

| Material Composition | Polymethyl methacrylate (PMMA) | Polyethylene terephthalate glycol-modified |

| Transparency | High clarity, up to 92% light transmission | Good clarity, around 89% light transmission |

| Impact Resistance | Moderate, prone to cracking under high stress | High impact resistance, flexible and durable |

| Scratch Resistance | Better scratch resistance compared to PETG | Lower scratch resistance, prone to surface marks |

| Weight | Lightweight, approx 1.19 g/cm3 | Slightly heavier, approx 1.27 g/cm3 |

| Chemical Resistance | Good resistance to acids and alkalis | Moderate chemical resistance, vulnerable to solvents |

| Thermal Resistance | Heat tolerance up to 80degC | Heat tolerance up to 70degC |

| Fabrication Ease | Requires careful handling during cutting and drilling | Easier to thermoform and shape |

| Cost | Generally more expensive | More cost-effective |

Introduction to Acrylic and PETG Displays

Acrylic displays offer high optical clarity, superior scratch resistance, and excellent UV stability, making them ideal for long-term visual presentations. PETG displays provide enhanced impact resistance, greater flexibility, and easier thermoforming capabilities, suitable for dynamic and curved display applications. Both materials serve distinct purposes in the display industry, with acrylic favored for rigidity and clarity, while PETG excels in durability and versatility.

Material Composition: Acrylic vs PETG

Acrylic displays are made from polymethyl methacrylate (PMMA), offering superior clarity, UV resistance, and rigidity compared to PETG displays, which are composed of glycol-modified polyethylene terephthalate, known for its impact resistance and flexibility. The molecular structure of acrylic provides a glass-like transparency and scratch resistance, making it ideal for high-visibility applications. PETG, while less rigid, excels in durability and ease of thermoforming, making it suitable for complex shapes and environments where impact resistance is critical.

Clarity and Visual Appeal Comparison

Acrylic displays offer superior clarity with a light transmittance of approximately 92%, resulting in exceptionally vibrant and sharp visuals compared to PETG displays, which typically have around 89% light transmittance. The higher optical clarity of acrylic ensures minimal distortion and reflects less yellowing over time, enhancing long-term visual appeal in retail and exhibition environments. PETG displays exhibit greater flexibility and impact resistance but sacrifice some clarity, making acrylic the preferred choice for applications prioritizing crisp, clear presentation.

Durability and Impact Resistance

Acrylic displays offer superior scratch resistance and clarity but are more prone to cracking under heavy impact compared to PETG displays. PETG displays provide enhanced impact resistance and flexibility, making them less likely to shatter or break when dropped or subjected to stress. Both materials balance durability and impact resistance differently, with acrylic excelling in surface hardness and PETG in resilience against force.

Weight Differences: Acrylic vs PETG

Acrylic displays are significantly lighter than PETG displays, with acrylic density averaging around 1.18 g/cm3 compared to PETG's higher density of approximately 1.27 g/cm3. This weight difference impacts portability and ease of installation, making acrylic a preferred choice for lightweight applications. Despite its lower weight, acrylic maintains high durability and optical clarity suitable for various display uses.

Cost Analysis: Which Is More Budget-Friendly?

Acrylic displays generally offer a more budget-friendly option compared to PETG displays due to lower raw material costs and easier manufacturing processes. PETG displays, while slightly more expensive, provide greater impact resistance and durability, justifying the higher initial investment for long-term use. When prioritizing cost-effectiveness, acrylic remains the preferred choice for budget-conscious projects and short-term applications.

Ease of Fabrication and Customization

Acrylic displays offer superior ease of fabrication compared to PETG displays due to their greater rigidity and ability to be precisely cut, drilled, and thermoformed without compromising structural integrity. Customization is more versatile with acrylic because it supports a wide range of finishing options, including polishing for optical clarity and vibrant color applications. PETG displays, while easier to thermoform in complex shapes, often require more post-processing to achieve comparable aesthetics and durability.

Applications: Best Uses for Acrylic and PETG Displays

Acrylic displays excel in applications requiring high optical clarity and scratch resistance, making them ideal for retail signage, museum cases, and point-of-purchase displays. PETG displays offer superior impact resistance and flexibility, suited for protective shields, food packaging, and outdoor signage exposed to harsher conditions. Both materials are widely used in display cases and exhibit panels, but acrylic's rigidity and clarity favor indoor use while PETG's durability supports rougher environments.

Environmental Considerations and Recyclability

Acrylic displays offer high clarity and durability but present environmental challenges due to their non-biodegradable nature and limited recycling options, often ending up in landfills. PETG displays, made from recyclable polyester, provide better environmental performance with easier recycling processes and a lower carbon footprint. Choosing PETG supports sustainability efforts by reducing plastic waste and promoting circular economy practices in display manufacturing.

Choosing the Right Display Material for Your Needs

Acrylic displays offer superior clarity, UV resistance, and scratch resistance compared to PETG, making them ideal for long-term use in retail and signage. PETG displays provide better impact resistance and flexibility, suitable for environments where durability and safety are priorities. Selecting the right display material depends on balancing acrylic's premium optical qualities with PETG's robust physical properties to match your specific application requirements.

Acrylic Display vs PETG Display Infographic

materialdif.com

materialdif.com