Acrylic rods offer solid, cylindrical shapes ideal for applications requiring strength and clear visibility, while acrylic tubes provide hollow structures suited for lightweight frameworks and fluid transport. Both materials exhibit excellent clarity, weather resistance, and ease of machining, making them versatile for diverse industrial and decorative uses. Choosing between acrylic rods and tubes depends on the specific mechanical and design requirements of the project.

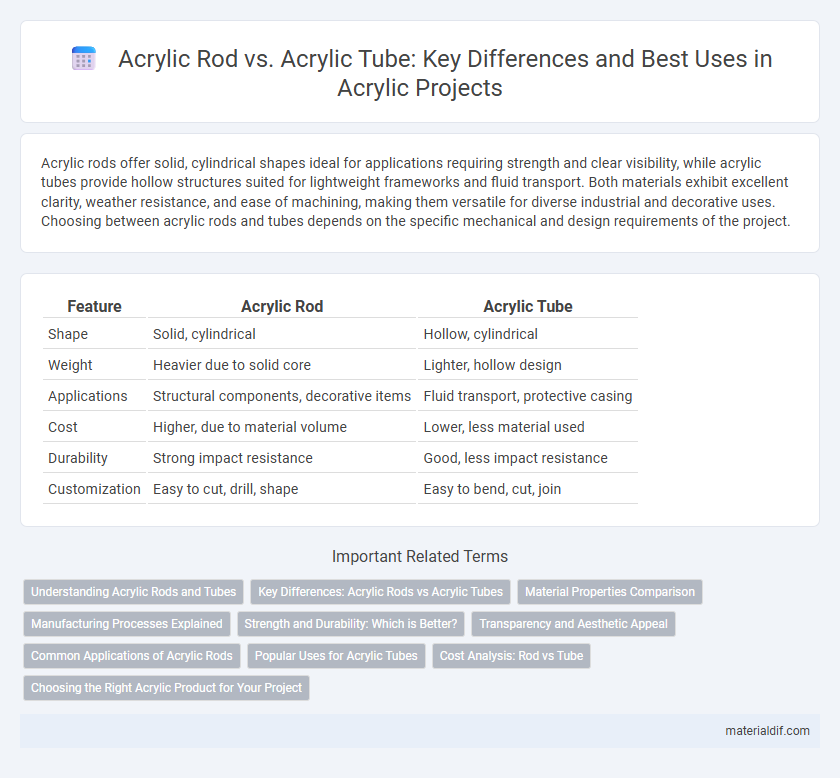

Table of Comparison

| Feature | Acrylic Rod | Acrylic Tube |

|---|---|---|

| Shape | Solid, cylindrical | Hollow, cylindrical |

| Weight | Heavier due to solid core | Lighter, hollow design |

| Applications | Structural components, decorative items | Fluid transport, protective casing |

| Cost | Higher, due to material volume | Lower, less material used |

| Durability | Strong impact resistance | Good, less impact resistance |

| Customization | Easy to cut, drill, shape | Easy to bend, cut, join |

Understanding Acrylic Rods and Tubes

Acrylic rods are solid cylindrical materials used for applications requiring strength and optical clarity, while acrylic tubes are hollow cylindrical structures designed for lightweight construction and fluid or wiring passage. Both rods and tubes share excellent weather resistance, high optical transparency, and superior impact resistance compared to glass. Selecting between acrylic rods and tubes depends on specific project needs such as load-bearing capacity, weight considerations, and design requirements.

Key Differences: Acrylic Rods vs Acrylic Tubes

Acrylic rods are solid cylindrical shapes primarily used for structural and decorative applications due to their strength and optical clarity, while acrylic tubes are hollow, designed for applications requiring lightweight, transparent piping or tubing solutions. Rods offer greater rigidity and are typically used in machining and fabrication, whereas tubes provide versatility in fluid transport and aesthetic design. The key differences lie in their construction--solid versus hollow--and their functional uses in industrial, architectural, and artistic projects.

Material Properties Comparison

Acrylic rods and acrylic tubes both offer excellent optical clarity and UV resistance, with rods typically exhibiting higher impact resistance due to their solid cross-section. Acrylic tubes, characterized by their hollow structure, provide greater flexibility and weight advantages, making them ideal for structural applications where reduced mass is critical. Both materials maintain superior weatherability and chemical resistance, but rods generally deliver enhanced strength and durability for machining and load-bearing uses.

Manufacturing Processes Explained

Acrylic rods and tubes are manufactured using distinct extrusion and casting methods tailored to their shapes; rods are typically produced through solid casting or extrusion to create cylindrical solids, while tubes require a more complex process involving extrusion or casting around a mandrel to form hollow cylinders. Casting involves pouring liquid acrylic into molds to achieve precise dimensions and optical clarity, whereas extrusion forces heated acrylic resin through shaped dies for continuous lengths with consistent cross-sections. Understanding these manufacturing processes highlights differences in strength, surface finish, and dimensional tolerances critical for selecting the right acrylic product for industrial or artistic applications.

Strength and Durability: Which is Better?

Acrylic rods generally exhibit higher strength and durability than acrylic tubes due to their solid, uniform structure, which provides better resistance to impact and stress. Acrylic tubes, while offering versatility and ease of fabrication, tend to be more prone to cracking or deformation under heavy loads because of their hollow design. For applications requiring maximum strength and long-lasting durability, solid acrylic rods are the superior choice over acrylic tubes.

Transparency and Aesthetic Appeal

Acrylic rods exhibit exceptional transparency with uniform clarity throughout their solid structure, making them ideal for applications requiring pristine optical properties. Acrylic tubes offer similar high transparency but provide an added aesthetic appeal through their hollow design, allowing for creative lighting effects and reduced weight in visual displays. Both materials maintain excellent UV resistance and brilliant gloss, enhancing their use in decorative and functional designs.

Common Applications of Acrylic Rods

Acrylic rods are widely used in optical and decorative applications due to their clarity, light transmission, and ease of machining. Common industries include signage, displays, and lighting, where rods function as light guides or structural elements. Their solid cross-section provides superior strength and durability compared to acrylic tubes, making them ideal for load-bearing and precise dimensional requirements.

Popular Uses for Acrylic Tubes

Acrylic tubes are widely used in applications requiring transparent, durable, and lightweight materials, such as display cases, aquariums, and protective barriers. Their hollow structure makes them ideal for fluid transport systems, lighting fixtures, and architectural installations where visibility and strength are essential. Compared to acrylic rods, tubes provide better versatility for engineering projects involving pipelines and decorative elements.

Cost Analysis: Rod vs Tube

Acrylic rods generally cost less per unit weight compared to acrylic tubes due to simpler manufacturing processes and lower material usage. Acrylic tubes often incur additional expenses for precision wall thickness and seamless extrusion, increasing overall pricing. When budget constraints are critical, selecting acrylic rods can provide a cost-effective solution, especially for applications not requiring hollow structures.

Choosing the Right Acrylic Product for Your Project

Acrylic rods offer solid, cylindrical forms ideal for structural support, display stands, and artistic projects requiring strength and clarity. Acrylic tubes, being hollow, are better suited for applications like fluid transport, protective covers, or lightweight frameworks where reduced weight and internal space are advantages. Selecting between acrylic rod and tube depends on specific project needs such as load-bearing capacity, transparency, weight considerations, and design flexibility.

Acrylic Rod vs Acrylic Tube Infographic

materialdif.com

materialdif.com